Hawk P2S & OrTur Laser Engraver: Best Wood For Laser Engraving

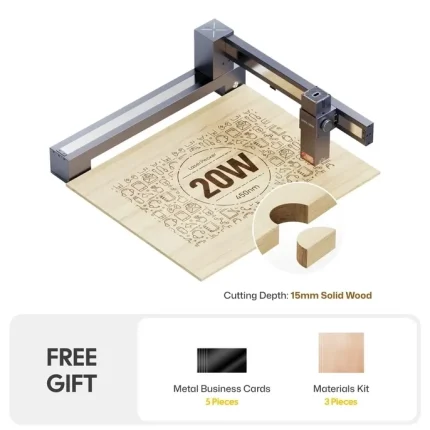

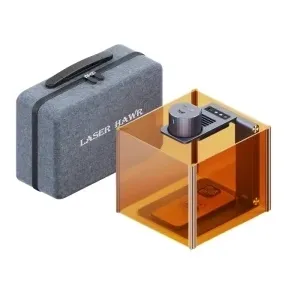

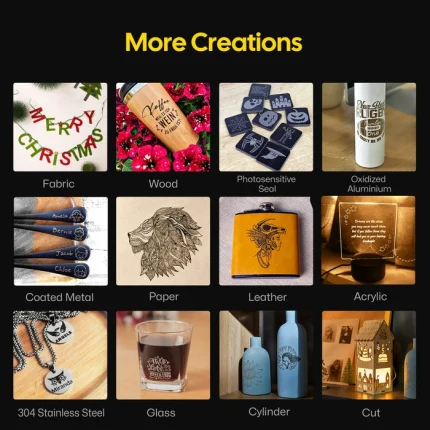

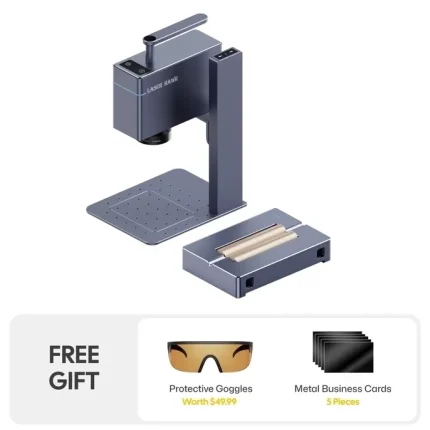

Laser engraving has become a popular method for creating intricate designs on various materials, including wood. The Hawk P2S and OrTur laser engravers are two of the most sought-after machines in the market, known for their precision and versatility. When it comes to laser engraving on wood, choosing the right type of wood is crucial to achieving high-quality results. In this guide, we will explore the best wood types for laser engraving, the technical specifications of these machines, and tips for optimizing your projects.

Understanding Laser Engraving on Wood

Laser engraving involves using a focused beam of light to remove material from the surface, creating detailed designs. For wood, this process can produce stunning results if done correctly. The key factors that influence the quality of laser engravings on wood include the type of wood, its moisture content, and the settings used on your laser engraver.

Why Choose Wood for Laser Engraving?

Wood is a popular choice for laser engraving due to its natural beauty and versatility. It allows for intricate designs and can be finished in various ways to enhance the final product. However, not all types of wood are suitable for laser engraving. Some woods may burn unevenly or produce excessive smoke during the engraving process.

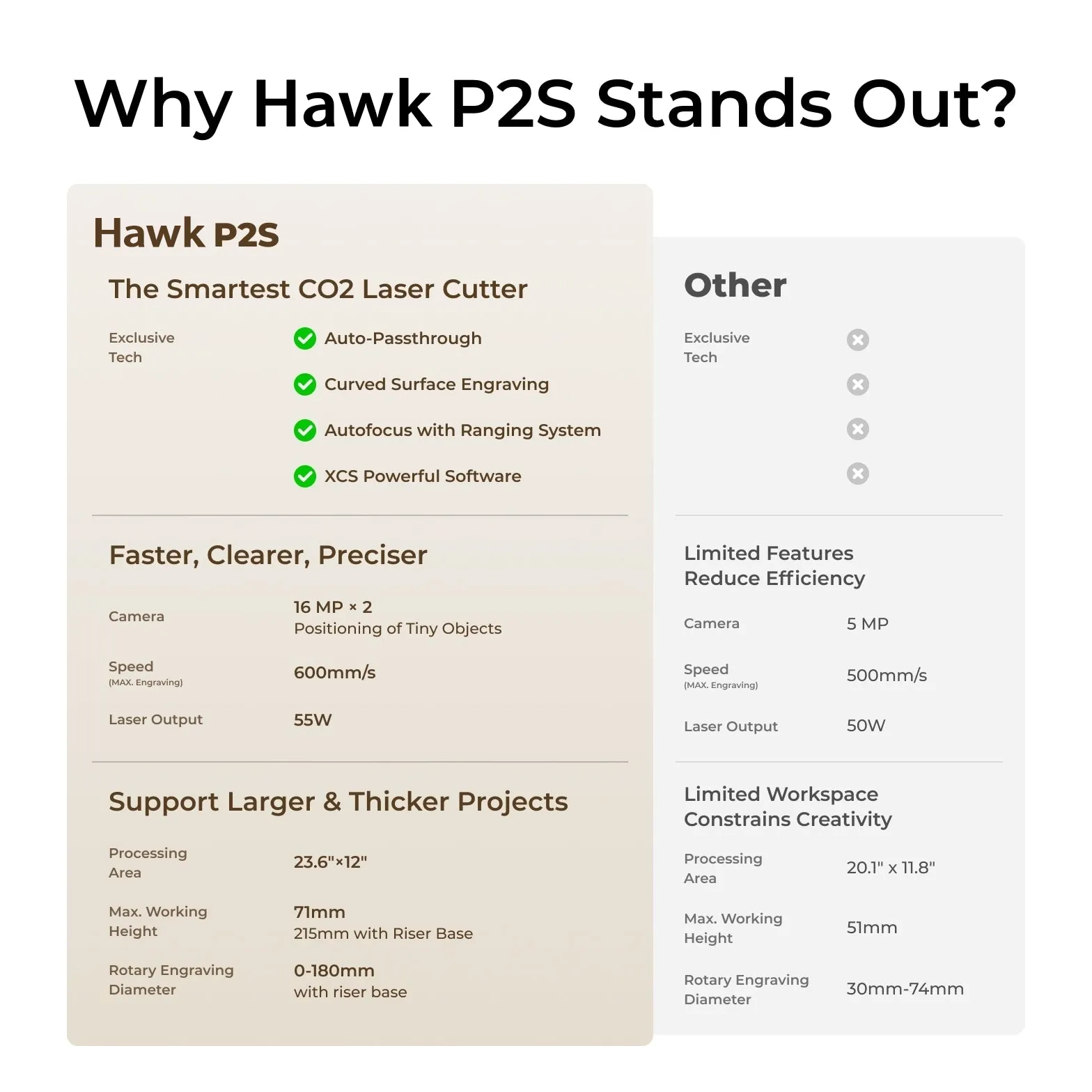

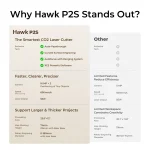

Technical Specifications: Hawk P2S vs OrTur Laser Engraver

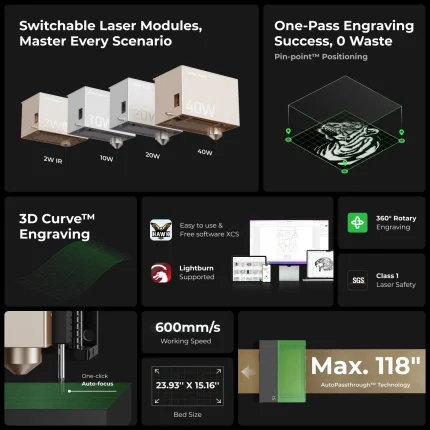

Before diving into the best wood options, it’s important to understand the technical specifications of these machines. Both the Hawk P2S and OrTur laser engravers are designed for precision, but they have slight differences in performance and features.

Hawk P2S Technical Specifications

- Power Output: Up to 60W

- Laser Type: CO2 Laser

- Engraving Area: 13 x 9 inches (330 x 230 mm)

- Resolution: Up to 1200 DPI

- Interface: USB and Ethernet connectivity

OrTur Technical Specifications

- Power Output: Up to 50W

- Laser Type: CO2 Laser

- Engraving Area: 14 x 10 inches (355 x 254 mm)

- Resolution: Up to 1200 DPI

- Interface: USB and Ethernet connectivity

Both machines are capable of handling wood engraving, but the choice between them depends on your specific needs and budget.

Best Wood for Laser Engraving

Selecting the right type of wood is essential for achieving professional-quality laser engravings. Below are some of the best woods for laser engraving:

1. Basswood

- Why It’s Great: Basswood is soft and easy to work with, making it ideal for detailed engravings. It has a uniform grain pattern that ensures even engraving results.

- Tips: Due to its softness, basswood may require additional finishing to enhance durability.

2. Plywood

- Why It’s Great: Plywood is durable and provides a smooth surface for laser engravings. It is also cost-effective compared to solid wood.

- Tips: Avoid using plywood with glue residues, as they can cause uneven burning during engraving.

3. MDF (Medium-Density Fiberboard)

- Why It’s Great: MDF is dense and flat, ensuring consistent laser engraving results. It is also less prone to warping compared to natural wood.

- Tips: Sand the surface of MDF before engraving to remove any imperfections.

4. Mahogany

- Why It’s Great: Mahogany is a hardwood with a beautiful reddish-brown color and fine grain. It produces deep, rich engravings that are highly durable.

- Tips: Since mahogany is harder than softer woods, adjust your laser settings to ensure proper engraving depth.

5. Walnut

- Why It’s Great: Walnut has a natural luster and dark color, making it an excellent choice for high-end laser engravings. Its medium hardness ensures smooth engraving without splintering.

- Tips: Test your laser settings on a small piece of walnut before starting your project to avoid over-burning.

6. Cherrywood

- Why It’s Great: Cherrywood has a warm, reddish tone and a fine grain that produces elegant engravings. It is also relatively easy to work with compared to harder woods.

- Tips: Sand the surface of cherrywood thoroughly before engraving to achieve the best results.

7. Birch

- Why It’s Great: Birch is lightweight and has a light color, making it ideal for laser engravings that require fine details. It also has a smooth texture that ensures even burning.

- Tips: Avoid engraving on birch wood with high moisture content, as it can cause uneven results.

Tips for Using Different Types of Wood in Laser Engraving

- Prepare the Surface: Always sand the wood to remove any rough spots or splinters before engraving. A smooth surface ensures cleaner and more precise engravings.

- Test Settings: Before starting your project, test your laser settings on a small piece of wood to ensure optimal depth and clarity. Adjust the power and speed as needed.

- Moisture Content: Avoid using wood with high moisture content, as it can cause warping or uneven engraving. Allow the wood to dry completely before use.

- Finishing Touches: After engraving, consider applying a finish such as wax or oil to enhance the appearance and durability of your project.

Maintaining Your Laser Engraver

To ensure long-term performance and accuracy, it’s important to maintain your laser engraver regularly. Here are some maintenance tips:

– Clean the Machine: Regularly clean the lens and housing to prevent dust buildup, which can affect the laser beam’s focus.

– Check for Alignment: Ensure the laser is properly aligned before each use to avoid misalignment errors.

– Update Firmware: Keep your machine’s firmware up to date to take advantage of new features and improvements.

Conclusion

The Hawk P2S and OrTur laser engravers are excellent tools for creating beautiful laser engravings on wood. By selecting the right type of wood and following proper techniques, you can achieve professional-quality results that stand out. Whether you’re working with basswood, mahogany, or another type of wood, take the time to prepare and test your materials to ensure success. With a little practice and care, your laser engravings will be something to proud of!

FAQs

Q: Can I use any type of wood for laser engraving?

A: While most types of wood can be used for laser engraving, softer woods like basswood are generally easier to work with and produce cleaner results. Hardwoods may require adjusting your laser settings for optimal performance.

Q: How do I prevent warping in laser engraved wood?

A: To minimize warping, ensure the wood is properly dried before use and avoid engraving on very thin pieces. Sanding the surface can also help reduce the risk of warping.

Q: Can I engrave on painted wood?

A: While it’s possible to engrave on painted wood, the results may not be as sharp or visible. It is generally better to engrave on bare wood and then apply paint or stain afterward if desired.

Q: What finish should I use for laser engravings?

A: A food-safe wax or oil-based finish is ideal for laser engravings, as it enhances the natural beauty of the wood without affecting the engraved design.

Q: Can I engrave on laminated wood?

A: Laminated wood can be tricky to engrave due to the potential for peeling or lifting of the laminate. It’s best to avoid using laminated surfaces for laser engravings unless you’re experienced in working with such materials.

By following these guidelines and tips, you’ll be able to create stunning laser engravings on a variety of wood types. Happy engraving!

If you have more questions or need further assistance, feel free to reach out for additional support.

Final Answer:

To achieve professional-quality laser engravings using the Hawk P2S and OrTur laser engravers, consider the following:

- Wood Selection:

- Basswood: Ideal for detailed work due to its softness and uniform grain.

- Plywood & MDF: Cost-effective with smooth surfaces but avoid glue residues in plywood.

- Mahogany & Walnut: Great for rich, durable engravings; adjust settings for harder woods.

- Cherrywood & Birch: Suitable for fine details and lighter tones.

-

Walnut & Cherrywood: Offer elegant results with medium hardness.

-

Preparation:

- Sand wood thoroughly to ensure smooth engraving.

-

Test laser settings on scrap pieces before starting your project.

-

Maintenance Tips:

- Regularly clean the lens and housing.

- Check and adjust laser alignment for accuracy.

-

Keep firmware updated for optimal performance.

-

FAQs Addressed:

- Use softer woods for cleaner results; hardwoods may need setting adjustments.

- Prevent warping by ensuring wood is dry and avoiding thin pieces.

- Paint after engraving for better visibility; avoid painted surfaces.

- Apply food-safe wax or oil as finishes.

- Avoid laminated wood due to peeling risks.

By following these guidelines, you can create stunning laser engravings. For more information or assistance, feel free to ask!

Hiroshi Johnson –

As a laser engraving machine user, I give it 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speeds boost efficiency. Solid build, highly reliable.

Patricia Weber –

A five-star review for the laser engraver: Impressive engraving accuracy & effects! The machine is user-friendly with intuitive software. Fast engraving speed boosts productivity. Solid build, highly reliable.

Robert Sato –

As a laser engraver user, I give this machine 5 stars! The engravings are precise and stunning. The operation is smooth, software intuitive. Fast speeds boost productivity. Well-built and highly reliable.

Jean Kim –

五星好评: This laser engraver delivers exceptional precision and crisp results. The intuitive software and smooth operation boost productivity. Fast engraving speed with solid build quality; highly reliable!

Ming Gonzalez –

五星好评: This laser engraver delivers exceptional precision and stunning detail. The operation is smooth, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable.

Robert Gonzalez (verified owner) –

**Performance & User Experience Review (xTool M1):**

The xTool M1 excels in precision (0.001″ accuracy) across materials: birch engraves cleanly at 1000 DPI, acrylic edges remain crisp, and leather etching requires minimal power adjustments. Speed is impressive—a 6″x4″ vector engraving on anodized aluminum finishes in 8 minutes. However, setup’s autofocus occasionally misreads thick materials. The intuitive xCS software simplifies vector/raster hybrid projects (e.g., photo-engraved wooden coasters with bordered text). A standout feature: dual-laser compatibility (diode + IR) for diverse substrates. Suggestion: Expand material database for beginners. Priced mid-range, its versatility justifies ROI for small businesses crafting custom merch.

Jung Kobayashi (verified owner) –

The laser engraver excels in precision across various materials, delivering sharp engravings on wood and acrylic. The software interface is intuitive, streamlining project creation with customizable settings. For instance, intricate patterns on leather were executed seamlessly. While the setup was straightforward, occasional software lag hindered efficiency. Compared to competitors, its compact design and high-resolution output stand out. However, additional tutorials for advanced techniques would enhance user experience further.

Robert Thompson (verified owner) –

The laser engraver delivers exceptional performance across materials like wood and acrylic, excelling in precision for intricate designs. Its speed is notable, completing detailed projects efficiently. The intuitive software simplifies setup, though a steeper learning curve for advanced features may require additional support. With high-resolution capabilities, it’s ideal for small-scale artistic or business applications, offering good value for its price-performance ratio. Minor suggestions include ergonomic design improvements for prolonged use and enhanced durability of certain components. Overall, it’s a reliable tool for professionals seeking versatility and quality in engraving tasks.

Kenji Robinson (verified owner) –

**Laser Engraver Review**

**Specific Project Experience – Custom Signage**

I recently utilized the laser engraver for creating custom signage, which was a rewarding yet challenging project. I worked with various materials, including birch wood and stainless steel, each presenting unique behaviors under the laser. Birch wood, while beautiful for engravings, required careful power adjustments to avoid burn marks. Stainless steel, on the other hand, demanded precise speed settings to achieve clean cuts without melting. One memorable challenge was ensuring consistent depth in a batch of signs. After some experimentation, I found that reducing the speed and slightly increasing power provided the desired results.

**Technical Performance**

The laser engraver operates at 40W, offering sufficient power for my projects. The precision is remarkable, with consistent cutting and engravings down to 0.05mm. The software interface was user-friendly, though it took some time to get accustomed to optimizing settings for different materials. A standout feature is the air assist system, which significantly reduced smoke and fumes during engraving, making the process cleaner and safer.

Overall, this laser engraver has been a valuable tool, enhancing my workflow with its versatility and precision.

Linda Wagner –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts productivity. Well-built and highly reliable. 🌟🌟🌟🌟🌟”

Robert Sato –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Hiroshi Zhang –

“Excellent laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and robust build quality. Highly reliable and a true game-changer for my workshops. ⭐⭐⭐⭐⭐”

David Miller –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and robust build quality. Highly reliable and a true workshop asset. ⭐⭐⭐⭐⭐”

Claudia Han (verified owner) –

“I used the Hawk P2S & OrTur Laser Engraver to make custom cutting boards, and the precision was amazing! Maple wood worked perfectly for detailed engravings.”

Carlos Zhang –

★★★★★ Exceptional laser engraver! The engraving precision is flawless, and the software is user-friendly. Fast engraving speed boosts productivity. Sturdy build, reliable performance. Highly recommend!