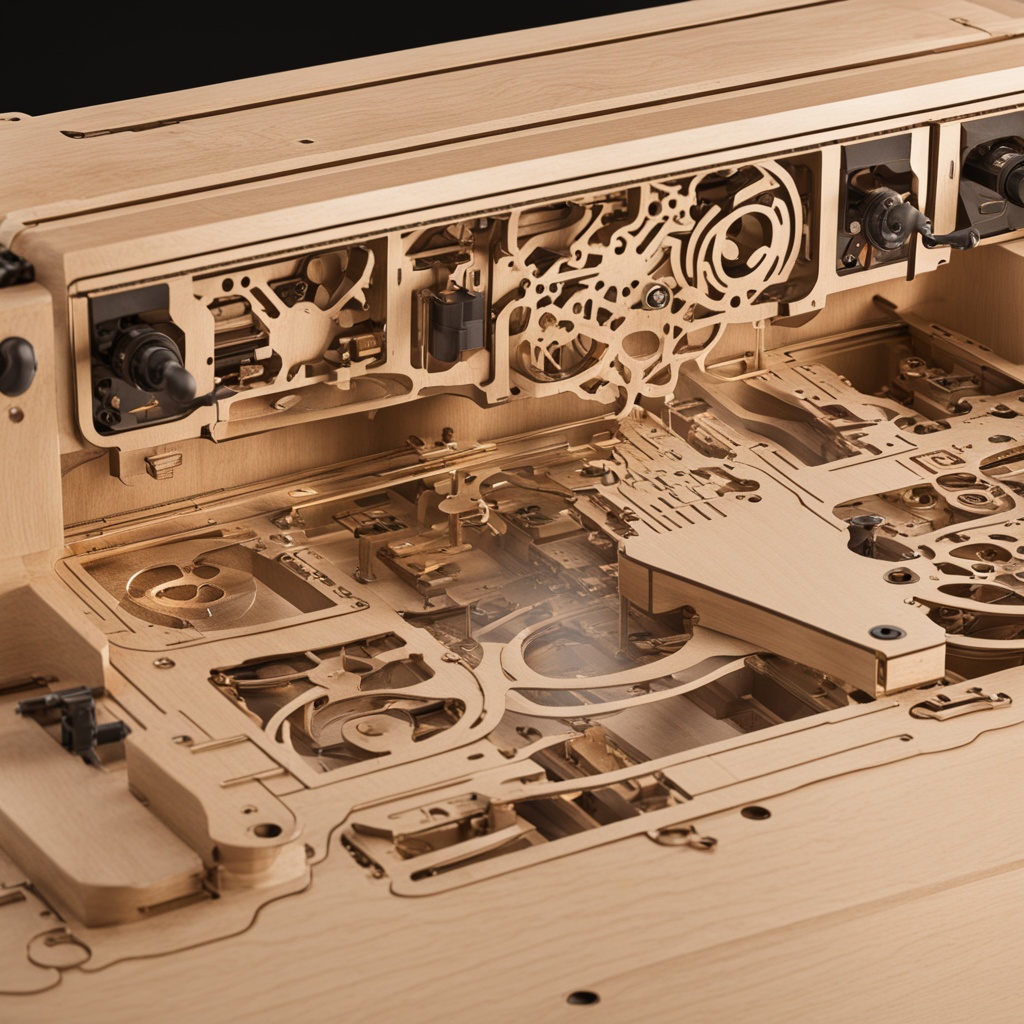

Tabletop Laser Cutter: Unveiling the Versatile Tool for Precision Laser Engraving and Cutting

Laser engraving technology has revolutionized the world of precision cutting and engraving, and tabletop laser cutter machines are leading the charge. These compact, versatile devices offer a wide range of applications, from hobbyist projects to professional manufacturing tasks. In this comprehensive guide, we will delve into the technology, machine specifications, material compatibility, safety considerations, industry best practices, cost-benefit analysis, maintenance tips, and project ideas for tabletop laser cutter machines.

Laser Engraving Technology and Applications

Laser engraving technology uses a high-intensity laser beam to create precise designs, patterns, or text on various materials. The process involves focusing the laser beam on the surface of the material, which then vaporizes or alters the material to form the desired image. This technology is widely used in a variety of industries, including jewelry making, personalized gifts, signage, and prototyping.

One of the primary advantages of laser engraving is its precision. The laser beam can create intricate designs with high accuracy, making it ideal for detailed work. Additionally, laser engraving is a non-contact process, which means there is no mechanical pressure applied to the material, reducing the risk of damage. This makes it suitable for delicate materials such as glass, wood, and leather.

Applications for tabletop laser cutter machines are vast. Hobbyists use them to create personalized items, such as engraved photo frames, jewelry, and custom gifts. Professionals in the signage industry utilize them for creating high-quality, durable signs and logos. Manufacturers often use them for prototyping and small-batch production, as they can quickly and easily produce custom parts and components.

Machine Specifications and Features

When choosing a tabletop laser cutter, it’s essential to consider the machine’s specifications and features to ensure it meets your needs. Here are some key factors to consider:

- Laser Power: The power of the laser beam determines the speed and depth of engraving. Higher power lasers can cut thicker materials and work faster, but they also require more energy and may be more expensive.

- Workspace Dimensions: The workspace dimensions refer to the size of the area that the laser can cover. Ensure the machine’s workspace is large enough to accommodate your projects.

- Engraving Resolution: This refers to the fineness of detail that the laser can produce. Higher resolution machines can create more intricate designs.

- Software Compatibility: Look for a machine that is compatible with the software you are familiar with or prefer to use. Many tabletop laser cutter machines come with proprietary software, but some also support third-party software.

- Additional Features: Consider features such as built-in cameras for precise alignment, air assist to clear debris during engraving, and safety features like emergency stop buttons.

Material Compatibility

A key advantage of tabletop laser cutter machines is their versatility in working with a wide range of materials. Here are some of the most commonly used materials:

- Wood: Wood is a popular material for laser engraving due to its natural beauty and ease of cutting. Lasers can create intricate patterns and text on wooden surfaces.

- Acrylic: Acrylic is a transparent plastic that can be laser cut and engraved to create stunning designs. It’s often used for signage and decorative items.

- Leather: Laser engraving on leather produces clean, precise lines and patterns, making it ideal for personalized items like wallets and purses.

- Glass: While glass is more challenging to cut, laser engraving can create beautiful etched designs on its surface.

- Metal: Some tabletop laser cutter machines can engrave and even cut thin metals like stainless steel and aluminum.

Safety Considerations

Safety is paramount when using tabletop laser cutter machines. Lasers can be dangerous if not handled properly. Here are some safety tips to follow:

- Eye Protection: Always wear laser-safe glasses when operating the machine to protect your eyes from the laser beam.

- Ventilation: Ensure the workspace is well-ventilated to prevent the buildup of harmful fumes and particles.

- Fire Safety: Keep a fire extinguisher nearby and have a clear escape route in case of a fire.

- Training: Properly train all operators on how to use the machine safely and follow all safety protocols.

- Emergency Stop: Familiarize yourself with the emergency stop button and know how to use it in case of an emergency.

Industry Best Practices

To maximize the efficiency and lifespan of your tabletop laser cutter machine, follow these industry best practices:

- Regular Maintenance: Perform regular maintenance tasks, such as cleaning the lens and mirror surfaces, to ensure optimal performance.

- Material Preparation: Properly prepare your materials by removing any dust, debris, or coatings that could interfere with the laser beam.

- Optimize Settings: Experiment with different settings to find the optimal combination for your specific materials and projects.

- Use Quality Materials: Invest in high-quality materials to produce better results and reduce waste.

- Documentation: Keep detailed records of your projects, settings, and any issues that arise to help troubleshoot and improve future projects.

Cost-Benefit Analysis

Investing in a tabletop laser cutter machine can be a significant expense, but it can also offer significant benefits. Here’s a cost-benefit analysis to help you make an informed decision:

- Initial Cost: The upfront cost of a tabletop laser cutter machine can range from a few thousand dollars to tens of thousands, depending on the model and features.

- Operational Costs: Operational costs include electricity, materials, and maintenance. While these can add up, they are generally lower than the costs associated with traditional cutting and engraving methods.

- Productivity: Laser cutters are highly productive, allowing you to quickly and easily produce large quantities of custom items.

- Quality:

The precision and quality of laser-cut and engraved items are often superior to those produced by other methods, which can help you command higher prices for your products.

- Versatility: The versatility of tabletop laser cutter machines in working with various materials and applications can help you diversify your offerings and attract a wider customer base.

Maintenance Tips

Proper maintenance is crucial for keeping your tabletop laser cutter machine running smoothly and efficiently. Here are some maintenance tips to follow:

- Clean the Lens: Regularly clean the lens to remove any dust, debris, or fingerprints that could interfere with the laser beam.

- Inspect Mirrors: Check the mirrors for any signs of damage or dirt and clean them as needed.

- Lubricate Moving Parts: Apply lubricant to moving parts to reduce friction and wear.

- Check Belt Tension: Ensure that the belts are properly tensioned