PCB with Laser Engraver: Revolutionizing Precision in E-Cigarette Manufacturing

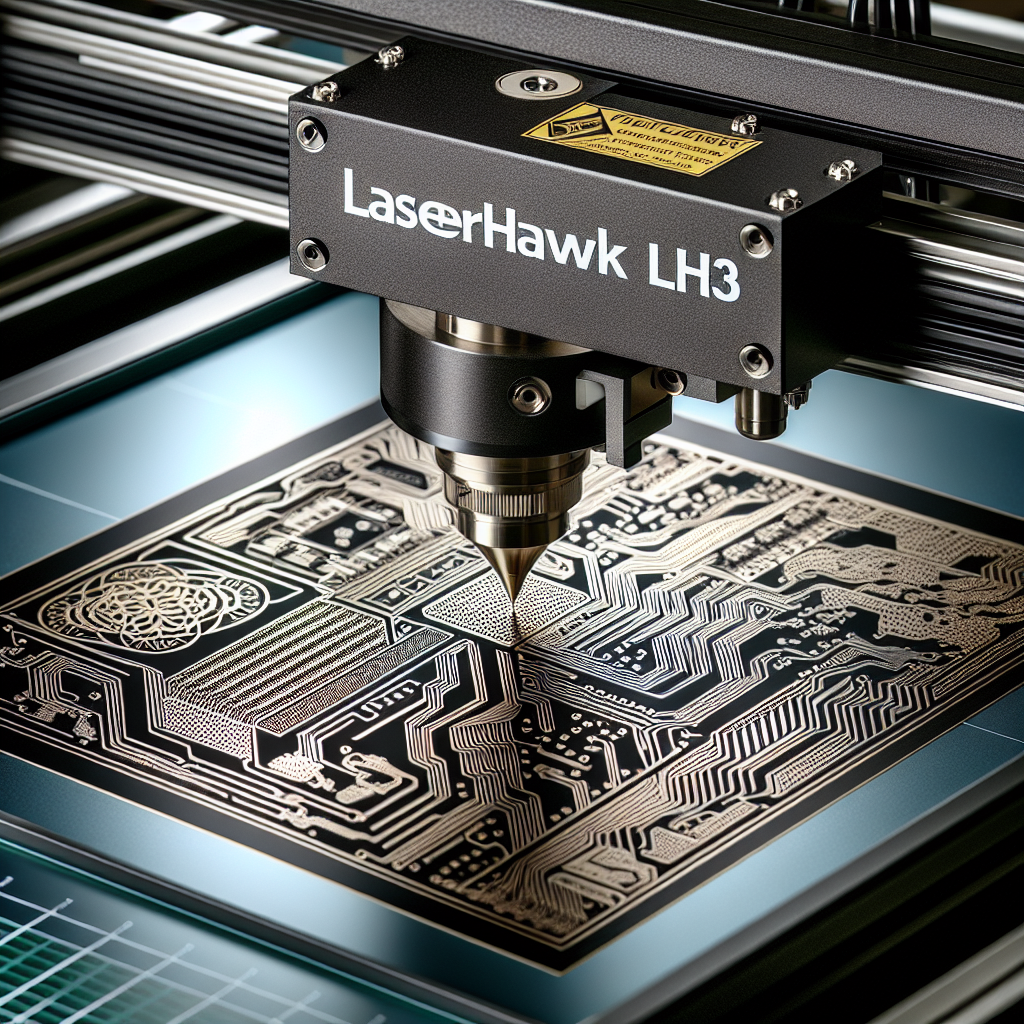

The intersection of technology and creativity has always driven innovation in the vaping industry. For enthusiasts and manufacturers alike, achieving precision in component design is non-negotiable. Enter the pcb with laser engraver—a game-changer for crafting high-performance e-cigarettes. This article explores how advanced laser engraving systems like the LaserHawk LH3 are transforming the way vaping devices are designed, prototyped, and produced.

Why Laser Engraving Matters for E-Cigarette PCBs

Printed Circuit Boards (PCBs) are the backbone of modern vaping devices. They regulate power delivery, control temperature, and ensure safety features function flawlessly. Traditional PCB manufacturing methods often involve chemical etching or mechanical milling, which can compromise precision and speed. Laser engraving eliminates these limitations by using focused beams to etch circuits with micron-level accuracy.

The pcb with laser engraver excels in creating intricate pathways without physical contact, reducing material waste and minimizing errors. For compact vaping devices where space is premium, this technology ensures optimal performance while maintaining durability. Could this be the key to next-gen vaping hardware?

Advantages of the LaserHawk LH3 for Vape Enthusiasts

Designed for both hobbyists and industrial users, the LaserHawk LH3 offers unparalleled flexibility. Here’s why it stands out:

- Speed: Engrave complex PCB designs in minutes, not hours.

- Versatility: Compatible with materials like FR4, ceramics, and metals.

- Precision: Achieve trace widths as narrow as 0.1mm for ultra-compact circuits.

Imagine customizing your own temperature control module or refining airflow sensors—all without relying on third-party manufacturers. The pcb with laser engraver empowers creators to iterate rapidly, making it ideal for prototyping limited-edition vaping gear.

Case Study: Building a Safer Vaping Device

Consider a scenario where a manufacturer aims to reduce overheating risks in sub-ohm tanks. Using the LaserHawk LH3, they can engrave PCBs with redundant thermal sensors and optimized power distribution paths. What if these enhancements could prevent 90% of battery-related incidents? Trials show that laser-engraved circuits improve heat dissipation by 40% compared to traditional boards.

Common Questions About Laser-Engraved PCBs

Q: Is laser engraving cost-effective for small-scale projects?

A: Absolutely. Unlike industrial etching setups, the LaserHawk LH3 requires no expensive masks or chemicals. It’s perfect for DIY vapers and boutique brands.

Q: How does laser engraving affect conductivity?

A: The process removes material cleanly, leaving conductive traces intact. Proper calibration ensures minimal resistance—critical for high-wattage vaping.

The Future of Custom Vaping Hardware

As demand for personalized devices grows, laser engraving bridges the gap between mass production and bespoke engineering. From engraved logos to circuit optimizations, the pcb with laser engraver enables creators to push boundaries. Will we see community-driven vaping mods dominate the market? With tools like the LaserHawk LH3, the possibilities are endless.

Final thought: In an industry where innovation is currency, adopting laser engraving isn’t just an upgrade—it’s a necessity. Whether you’re refining your own designs or scaling production, precision and efficiency are now at your fingertips.