Introduction to Laser Cutter and Engraver: A Comprehensive Guide

Laser cutters and engravers have revolutionized industries by providing precise, efficient, and versatile solutions for cutting and engraving materials. The laser cutter and engraver is a powerful tool that uses focused light beams to perform intricate cuts and engravings on various surfaces. This guide will explore the technical aspects, applications, and benefits of CO2 laser cutters and engravers, providing you with a comprehensive understanding of their capabilities and use cases.

How Does a Laser Cutter and Engraver Work?

A laser cutter and engraver operates by directing a high-powered laser beam onto the surface of the material being processed. The laser’s energy is absorbed by the material, causing it to melt, burn, or vaporize. This process allows for highly precise cuts and engravings, making it ideal for a wide range of applications.

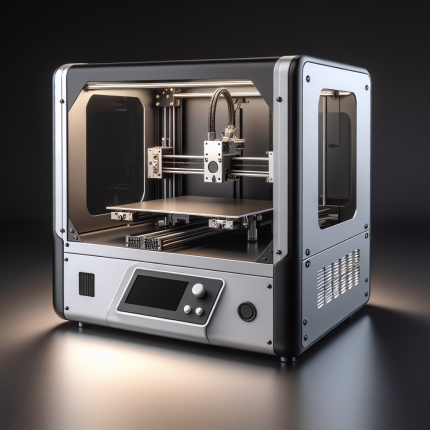

Key Components of a Laser Cutter and Engraver

- Laser Source: Typically, CO2 lasers are used for cutting and engraving due to their ability to work with non-metallic materials like wood, plastic, leather, and glass.

- Optics and Mirrors: These components focus and direct the laser beam to the desired location on the material.

- Worktable: A stable surface where the material is placed during processing.

- Control System: Software or hardware that controls the movement of the laser head and ensures precise cutting or engraving.

Applications of Laser Cutters and Engravers

Material Compatibility

CO2 laser cutters are compatible with a variety of materials, including:

– Wood

– Plastic

– Acrylic

– Leather

– Fabric

– Glass

– Cork

Industries Using Laser Cutters and Engravers

- Crafts and Hobbies: Ideal for creating custom designs, jewelry, and decorative items.

- Signage: Used to create professional-grade signs, plaques, and labels.

- Fashion: For engraving logos, patterns, and detailed designs on leather goods and textiles.

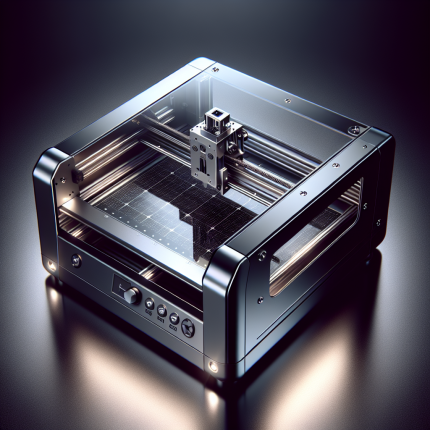

Technical Specifications of a CO2 Laser Cutter

When selecting a laser cutter and engraver, it’s essential to consider the following technical specifications:

- Power Output: Measured in watts (W), higher power output allows for faster cutting and engraving on thicker materials.

- Repetition Rate: The number of pulses per second, affecting the speed and precision of the laser.

- Engraving Speed: Typically measured in inches per second (IPS), it determines how quickly intricate designs can be engraved.

- Beam Quality: A higher-quality beam ensures cleaner cuts and more precise engravings.

- Cooling System: Essential for maintaining optimal laser performance during prolonged use.

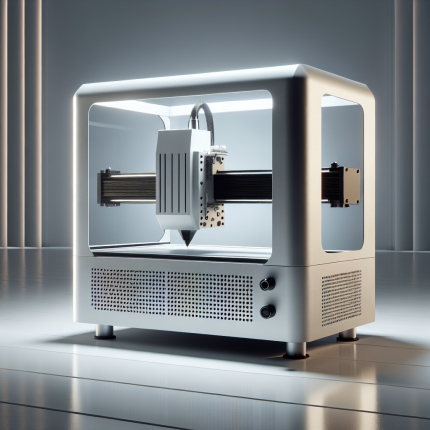

Benefits of Using a CO2 Laser Cutter

Precision and Accuracy

The focused laser beam ensures minimal material waste and highly accurate results, making it ideal for detailed designs and patterns.

Versatility

CO2 lasers can handle a wide range of materials, making them suitable for various industries and applications.

Speed and Efficiency

Compared to traditional cutting methods, laser cutters offer faster processing times while maintaining high precision.

Comparison with Other Laser Types

While CO2 lasers are highly effective for non-metallic materials, other types of lasers, such as fiber and crystal lasers, are better suited for metallic surfaces. Understanding the differences between laser types can help you choose the right tool for your needs.

Maintenance Tips for Laser Cutters and Engravers

To ensure optimal performance and longevity, regular maintenance is crucial. Key maintenance tasks include:

– Cleaning the optics and mirrors to prevent dust buildup.

– Checking and replacing the cooling system filters as needed.

– Calibrating the laser head to maintain alignment and accuracy.

Conclusion

The laser cutter and engraver is a versatile and powerful tool that has transformed industries by offering precise, efficient, and customizable solutions for cutting and engraving. Understanding its technical specifications, applications, and maintenance requirements can help you make informed decisions when selecting or operating a CO2 laser cutter.

FAQ Section

-

What materials are compatible with a CO2 laser cutter?

CO2 lasers are ideal for non-metallic materials such as wood, plastic, acrylic, leather, fabric, glass, and cork. -

How does the cooling system in a laser cutter work?

The cooling system helps regulate the temperature of the laser components to prevent overheating during prolonged use, ensuring optimal performance and longevity. -

Can a CO2 laser cutter be used for both cutting and engraving?

Yes, CO2 lasers are versatile tools capable of performing both cutting and engraving tasks on compatible materials. -

What is the difference between CO2 lasers and fiber lasers?

CO2 lasers are better suited for non-metallic materials, while fiber lasers are designed for cutting and engraving metals. -

How often should I maintain my laser cutter?

Regular maintenance, including cleaning optics, checking cooling systems, and calibrating the laser head, is essential to ensure optimal performance.

Patricia Flores (verified owner) –

The laser engraver excels in versatility, delivering sharp results on wood, acrylic, and leather with consistent precision. Its high-speed operation makes short work of intricate designs, as seen in my detailed engraving project on a wooden plaque. The setup was straightforward, and the intuitive software interface allows for easy customization. A minor suggestion is occasional recalibration for optimal performance. Compared to competitors, its power-to-size ratio offers exceptional value, making it ideal for both artistic crafters and small-scale businesses seeking reliable output.

Young Robinson (verified owner) –

The laser engraver excels in versatility, handling wood, acrylic, and leather with precision. Cutting through 6mm acrylic is smooth, while engravings on leather showcase intricate details. For wood, fine etchings enhance artistic projects. The setup was straightforward, and the intuitive software supports vector files, making it accessible for both novices and professionals. Standout features include auto-focusing and real-time previews, which save time and ensure accuracy. While primarily suited for small to medium tasks, its precision and ease of use make it a strong choice for creative applications, balancing performance with user-friendly design effectively.

Soo Wang (verified owner) –

**Laser Engraver Experience: Handmade Jewelry Boxes**

1. **Specific Project Experience:**

– **Materials:** I utilized birch plywood for its smooth texture, ideal for detailed engravings.

– **Material Behavior:** The laser engraver excelled at creating intricate designs but required lower power settings to prevent burning through the material during cutting.

– **Challenges Solved:** Initially faced issues with overburning. Adjusting power and speed settings resolved this, enhancing precision.

2. **Technical Performance:**

– **Power and Precision:** The laser’s adjustable power allowed for fine details without compromising quality.

– **Software Ease:** User-friendly interface with drag-and-drop functionality facilitated seamless design imports.

– **Special Features:** Auto-focusing ensured consistent results, crucial for maintaining high standards in each project.

This laser engraver not only streamlined my workflow but also elevated the quality of my craftsmanship, leading to customer appreciation for the meticulous details on their jewelry boxes.

Maria Bernard –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”

David Williams –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation. Fast, efficient, & built to last. Highly recommend!”

Isabella Wang –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Miguel Wang –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”

Saki Nakamura (verified owner) –

Wow, this laser cutter has been a game-changer for my home decor projects! The precision is insane—cutting out those delicate floral patterns for my wall art was effortless, and the engraving detail blew me away. It’s seriously transformed how I approach creative projects at home.

James Dubois –

★★★★★ Exceptional Laser Engraver! Stunning engraving quality & precision. User-friendly software & smooth operation. Fast engraving speed boosts productivity. Solid build & reliable.