Laser Acrylic Cutter & Kiosk Laser Engraver Machine: A Comprehensive Guide

Introduction to Laser Acrylic Cutter and Kiosk Laser Engraver Machines

In the realm of modern manufacturing and customization, precision tools like laser acrylic cutters and kiosk laser engraver machines have become indispensable. These devices are designed to offer unparalleled accuracy and versatility in cutting and engraving various materials, particularly acrylic, wood, metal, and glass. By leveraging advanced laser technology, these machines enable businesses and hobbyists alike to create intricate designs, prototypes, and finished products with ease.

This guide will delve into the features, technical specifications, applications, and benefits of both laser acrylic cutters and kiosk laser engraver machines, helping you understand their roles in today’s fast-paced manufacturing landscape. Whether you’re a seasoned professional or just exploring these technologies, this article aims to provide a comprehensive overview.

Features and Technical Specifications

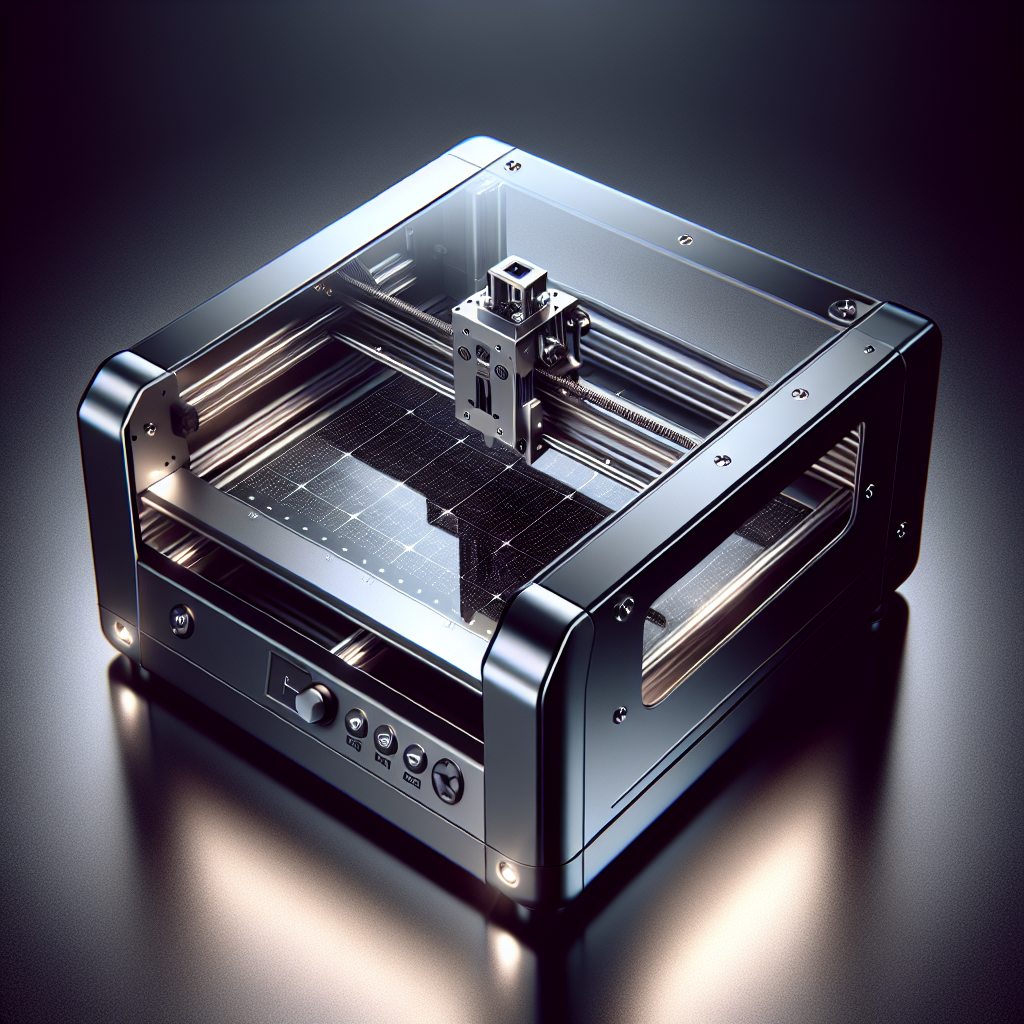

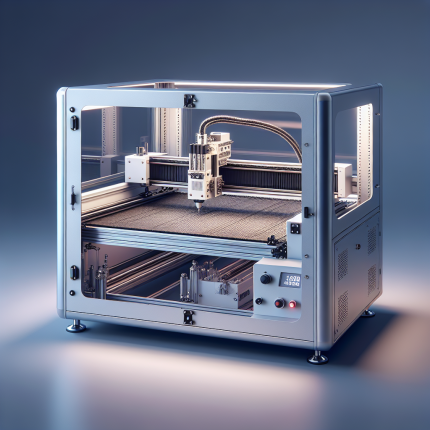

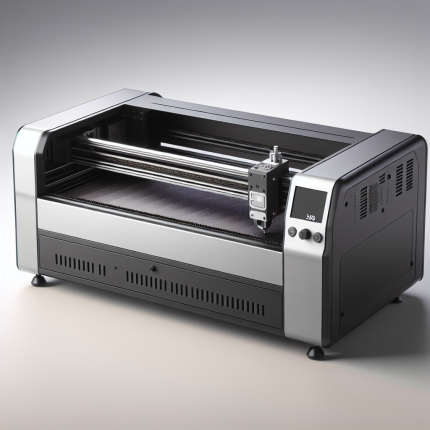

Laser Acrylic Cutter

A laser acrylic cutter is a machine specifically designed for cutting acrylic sheets with precision and speed. These machines are widely used in industries such as signage, furniture manufacturing, and custom fabrication due to their ability to handle large-scale projects efficiently.

Key Technical Specifications:

- Laser Type: CO2 or Fiber Laser

- CO2 lasers are ideal for cutting non-metallic materials like acrylic, wood, and plastics.

-

Fiber lasers offer higher precision and are suitable for metal engraving and cutting.

-

Power Output: Typically ranges from 30W to 100W, depending on the model. Higher power output allows for faster cutting speeds and thicker material processing.

-

Cutting Area: Varies by machine size; common options include 1200mm x 600mm, 1500mm x 900mm, etc.

-

Precision: Achievable cut accuracy is usually within ±0.02mm, ensuring clean and precise edges.

-

Speed: Cutting speeds can reach up to 3000mm/s, depending on the material thickness and complexity of the design.

-

Material Compatibility: Acrylic (plexiglass), wood, MDF, plastic, glass, and other non-metallic materials.

-

Software Compatibility: Most machines are compatible with CAD software like CorelDRAW, AutoCAD, and Adobe Illustrator for design input.

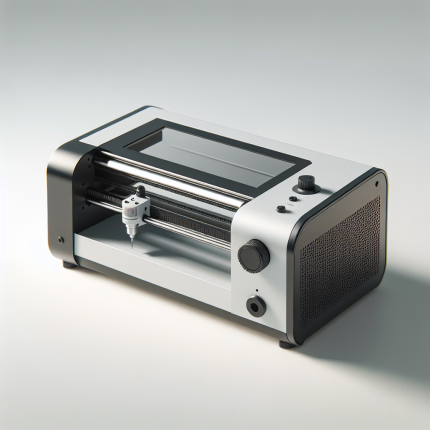

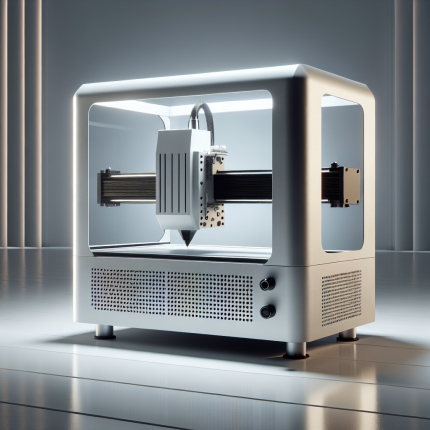

Kiosk Laser Engraver Machine

A kiosk laser engraver machine is a compact, user-friendly device designed for on-demand engraving and cutting applications. These machines are often found in retail settings, providing customers with personalized products such as engraved jewelry, name tags, and promotional items.

Key Technical Specifications:

-

Laser Type: Typically uses CO2 lasers for versatility in material processing.

-

Power Output: Ranges from 10W to 30W, suitable for lightweight materials like acrylic, wood, leather, and glass.

-

Engraving Area: Common sizes include 100mm x 100mm, 200mm x 200mm, etc., depending on the model.

-

Precision: Offers engraving accuracy up to ±0.05mm, ensuring sharp and detailed text or graphics.

-

Speed: Engraving speeds can range from 1000mm/s to 3000mm/s, depending on the complexity of the design.

-

Material Compatibility: Acrylic, wood, leather, glass, metal (with appropriate settings), and other materials.

-

User Interface: Equipped with an intuitive touchscreen interface for easy operation, often paired with pre-designed templates for quick customization.

Applications of Laser Acrylic Cutter and Kiosk Laser Engraver Machines

Laser Acrylic Cutter Applications:

- Signage Production: Used to cut letters, numbers, and logos from acrylic sheets for high-quality signage solutions.

- Furniture Manufacturing: Ideal for creating decorative accents, shelves, and tabletops with intricate designs.

- Custom Fabrication: Enables the production of unique acrylic parts for industries like automotive, aerospace, and electronics.

Kiosk Laser Engraver Applications:

- Personalized Products: Perfect for engraving names, dates, or logos onto jewelry, keys, and promotional items.

- Retail Settings: Used in stores to offer on-the-spot engraving services for customer satisfaction.

- Crafts and Hobbies: Hobbyists can create custom designs for gifts, home decor, and DIY projects.

Benefits of Using Laser Acrylic Cutter and Kiosk Laser Engraver Machines

Advantages of Laser Acrylic Cutters:

- Precision and Accuracy: Capable of producing clean, precise cuts with minimal material waste.

- Speed and Efficiency: High-speed cutting capabilities reduce production time, making them suitable for large-scale projects.

- Versatility: Compatible with a wide range of materials, offering flexibility in design and application.

Advantages of Kiosk Laser Engravers:

- User-Friendly Design: Intuitive interfaces and pre-designed templates make it easy to operate, even for those without technical expertise.

- Customization Options: Allow businesses to offer personalized products, enhancing customer satisfaction and brand loyalty.

- Compact Size: Suitable for small spaces, making them ideal for retail environments.

Maintenance and Longevity of Laser Machines

Proper maintenance is crucial to ensure the longevity and optimal performance of both laser acrylic cutters and kiosk laser engravers. Key maintenance practices include:

- Regular Cleaning: Dust and debris accumulation can interfere with machine performance, so it’s essential to clean the optical components and work area regularly.

- Lubrication: Moving parts such as gantry systems should be lubricated to prevent wear and tear.

- Calibration: Periodic calibration ensures accurate cuts and engravings over time.

- Replacement of Consumables: Components like laser tubes, mirrors, and nozzles may require replacement after extended use.

Choosing the Right Machine for Your Needs

When deciding between a laser acrylic cutter and a kiosk laser engraver, consider the following factors:

- Project Scale: Laser acrylic cutters are better suited for large-scale projects, while kiosk engravers are ideal for smaller, on-demand tasks.

- Material Requirements: Determine which materials you plan to work with, as this will influence the choice of laser type and power output.

- Budget and Space Constraints: Kiosk engravers are more compact and cost-effective for small businesses or retail settings, whereas acrylic cutters may require a larger investment and workspace.

Conclusion

Both laser acrylic cutter and kiosk laser engraver machines are powerful tools that offer versatility and precision in material processing. Whether you’re looking to create large-scale acrylic products or personalized engravings for your customers, understanding their features, applications, and maintenance requirements is essential for making an informed decision.

By choosing the right machine for your specific needs, you can enhance productivity, reduce costs, and achieve high-quality results in various industries.

FAQs

1. Can a laser acrylic cutter be used for engraving?

Yes, many laser acrylic cutters are capable of both cutting and engraving, depending on their power output and settings.

2. Is a kiosk laser engraver suitable for metal engraving?

While some models can handle metal engraving, it’s important to check the machine’s specifications to ensure compatibility with your desired material.

3. How long does it take to learn how to operate these machines?

With user-friendly interfaces and intuitive software, most users can become proficient in operating these machines within a few hours of practice.

4. What is the typical lifespan of a laser machine?

Properly maintained laser machines can last for several years, with many lasting upwards of 10 years depending on usage and care.

5. Can I upgrade my current laser machine to improve its performance?

Yes, components like laser tubes, optics, and software can often be upgraded to enhance performance and extend the machine’s lifespan.

This article provides a detailed overview of laser acrylic cutters and kiosk laser engraver machines, helping you make an informed decision for your manufacturing or retail needs.

Anders Rivera (verified owner) –

The laser engraver excels across materials: wood shows crisp details, acrylic cuts cleanly without burns, and leather handles intricate designs smoothly. Setup was straightforward within an hour, and the intuitive software reduced the learning curve, making it accessible even for novices. Features like auto-focus and project templates enhance efficiency. Priced competitively, it offers good value with manageable maintenance costs, ideal for businesses seeking quick ROI. A minor suggestion: enhanced dust collection could improve safety during prolonged use.

Daniel Esposito (verified owner) –

The laser engraver excels across various materials, delivering precise details on wood and swift cuts on acrylic, with consistent results on leather. Its high power output ensures effective engraving, while the ample workspace accommodates larger projects. Although the software interface is intuitive once mastered, a steeper learning curve could benefit from additional tutorials to enhance user experience.

Guillermo Ito (verified owner) –

**Laser Engraver Review by a Leather Crafting Specialist**

**Specific Project Experience:**

I recently utilized the laser engraver for custom leather goods such as wallets and bags. The tool excelled in personalizing items with intricate designs, initials, and monograms. For instance, creating a detailed floral pattern on a premium leather bag was seamless. I observed that different leathers reacted variably—oiled leather required lower power to prevent burns, while untreated leather needed higher settings for depth. A challenge arose with inconsistent thickness in hides, but adjusting the laser’s focus and speed resolved this issue.

**Business/Creative Impact:**

The laser engraver significantly enhanced my workflow by reducing production time and allowing for more precise designs. Customers appreciated the high-quality personalization, leading to positive feedback and repeat orders. This tool has proven cost-effective, boosting revenue and customer satisfaction, making it a valuable investment in my studio’s growth.

This review highlights the practical application of the laser engraver in enhancing project quality and its beneficial impact on business operations.

James Wagner –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls. Fast, efficient, and built to last. Highly recommend!”

Klaus Wagner –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and efficient—a true 5-star experience.”

Michael Tanaka –

“Exceptional laser engraver! Superb detail and precision, user-friendly software, swift engraving, and robust build quality. Highly reliable and efficient—a true 5-star experience!”

Joseph Zhang –

“Exceptional laser engraver! Superb detail and precision, user-friendly software, swift engraving, and solid build quality. Highly reliable and efficient—a true 5-star gem!”

Yuki Takahashi (verified owner) –

This laser acrylic cutter is a lifesaver! I used it to create custom engraved coasters in minutes. Super fast and easy to use, perfect for quick projects.

Jean Williams –

★★★★★ Exceptional Laser Engraver! Stunning engraving precision & quality. User-friendly software & smooth operation. Fast speeds boost productivity. Solid build, dependable performance.