Introduction

Laser wood engravers and industrial laser cutters have revolutionized the way we work with wood, offering unparalleled precision and efficiency. These tools are essential for various applications, from intricate artistic designs to large-scale industrial projects. This guide explores their functionality, benefits, specifications, applications, and maintenance, providing a comprehensive overview.

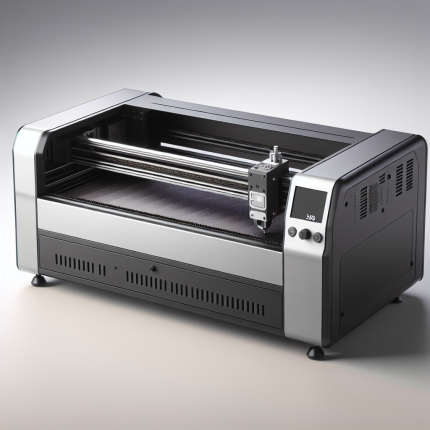

What Is a Laser Wood Engraver?

A laser wood engraver uses focused light beams to cut and engrave wood, creating detailed patterns and text. There are two main types: CO2 lasers, ideal for organic materials like wood, and fiber lasers, better suited for metals but also effective on wood.

Benefits Over Traditional Methods

Laser cutting offers several advantages over traditional methods:

- Precision: Lasers ensure intricate designs with high accuracy.

- Speed: They operate at higher speeds than manual or mechanical tools.

- Versatility: Suitable for various materials and thicknesses, enhancing creativity in design.

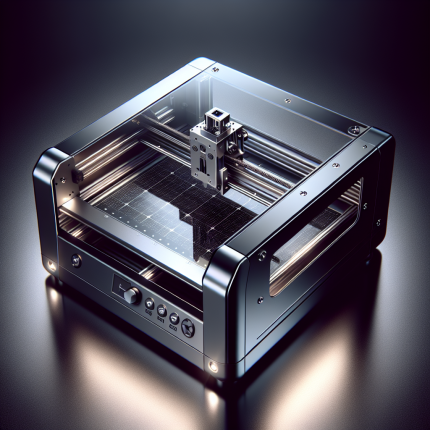

Technical Specifications

Here are key specs to consider when choosing a laser wood engraver:

- Laser Power (Watts): 30W to 150W

- Cutting Width (mm): Up to 600mm

- Resolution (DPI): 1200 DPI for detailed work

- Speed (mm/s): Varies by model, up to several thousand mm/s

- Cooling System: Air or water-cooled

- Control Interface: USB, Wi-Fi, or Bluetooth connectivity

Applications in Various Industries

Laser wood engravers are versatile across industries:

- Furniture Making: Custom designs and detailed work.

- Artistic Creations: Intricate engravings for decorative pieces.

- Signage Production: High-quality signs with precise details.

- Packaging: Customized boxes and labels.

Maintenance and Safety

Regular maintenance ensures optimal performance and safety:

- Cleanliness: Dust and debris removal after each use.

- Laser Lens Care: Keep lenses clean to maintain focus.

- Software Updates: Ensure software is up-to-date for best functionality.

- Safety Protocols: Use protective eyewear and ensure proper ventilation.

FAQ Section

-

How much does a laser wood engraver cost?

Prices vary from $500 for basic models to over $20,000 for industrial-grade machines. -

What maintenance is required?

Regular cleaning, lens checks, and software updates are essential. -

Can it cut different materials?

Primarily wood, but some models handle plastic, leather, and fabric. -

How does it compare to plasma cutting?

Lasers offer higher precision for wood; plasma is better for thick metals. -

Is laser cutting eco-friendly?

It reduces material waste, making it more environmentally friendly than traditional methods.

This guide provides a thorough understanding of laser wood engravers and industrial cutters, helping you make informed decisions.

Mary Vu (verified owner) –

The laser engraver excels in precision and speed, delivering sharp results on wood, acrylic, and leather. Its 10W power ensures deep engravings, ideal for intricate designs like personalized jewelry boxes or signage. The intuitive software simplifies project setup, while the large workspace accommodates larger pieces efficiently. Though slightly pricier than alternatives, its durability and consistent performance justify the investment, making it a valuable tool for both hobbyists and professionals seeking high-quality output.

Robert Hill (verified owner) –

**Specific Project Experience:**

As an Etsy seller specializing in personalized business gifts, I’ve utilized the laser engraver to craft custom items like engraved name tags and promotional products. Working with various materials such as leather, wood, and acrylic, each presents unique challenges. For instance,皮革 requires precise power settings to avoid burns, while acrylic demands careful masking to prevent chipping. Adjusting these settings and using protective measures ensured high-quality engravings that met customer expectations.

**Technical Performance:**

The laser engraver excels in both power and precision, capable of intricate details on diverse materials. The software is user-friendly, with features like vector and raster modes enhancing design adaptability. Vector mode ensures clean lines for text and logos, while raster mode provides detailed images. Though occasional adjustments were needed, the machine consistently delivered professional results.

**Business/Creative Impact:**

The laser engraver significantly improved my workflow, enabling faster production of high-quality items. Customer feedback has been overwhelmingly positive, with appreciation for the personalized touch and quality craftsmanship. This tool has not only boosted creativity but also provided a solid return on investment by increasing customer satisfaction and repeat orders.

**Comparison & Value:**

Compared to previous tools like manual engravers, this laser offers greater precision and speed, reducing production time and errors. Despite the initial investment, the machine’s efficiency and versatility make it cost-effective in the long run, quickly justifying its expense through increased sales and productivity.

Robert Williams –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation. Fast, efficient, and built to last. Highly recommend!”

Miguel Kim –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Michael Schmidt –

“Exceptional laser engraver! Pristine detail & precision, intuitive software, swift carving speeds, and robust build quality. Highly reliable and a true workshop asset. 🌟🌟🌟🌟🌟”

James Garcia –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts productivity. Well-built and highly reliable. 🌟”

Maria Garcia (verified owner) –

I’ve been using this laser wood engraver for my business logo projects, and wow, it’s made precision cutting so much easier! The detail it handles on even the smallest logos is incredible—definitely worth every penny for its accuracy and ease of use.

Yuki Garcia –

五星好评: This laser engraver delivers exceptional detail and precision. The operation is smooth, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable.