Mastering Laser Engraving on Metal: A Comprehensive Guide

Laser engraving on metal has become one of the most popular methods for creating intricate designs, logos, and patterns with precision and durability. Whether you’re a hobbyist or a professional artist, this technique offers unparalleled control over your projects. In this article, we’ll explore everything you need to know about laser engraving on metal, including its advantages, essential tools, and tips for achieving stunning results. Let’s dive in!

What is Laser Engraving on Metal?

Laser engraving on metal involves using a focused laser beam to etch designs or patterns onto the surface of metal. This process removes material layer by layer, creating permanent and highly detailed engravings. Unlike traditional methods like acid etching or mechanical engraving, laser engraving is fast, precise, and non-contact, making it ideal for delicate surfaces.

If you’re new to this technology, you might be wondering, how does a laser engraver work? The machine uses a high-power laser beam that generates intense heat, vaporizing the metal surface in specific areas. This process is controlled by software, allowing for intricate designs and patterns to be replicated with remarkable accuracy.

The Advantages of Laser Engraving on Metal

Laser engraving on metal offers numerous benefits compared to traditional methods. Here are some key advantages:

- Precision and Detail: Lasers can create extremely fine lines and intricate patterns that would be impossible with manual tools.

- Durability: The engravings are permanent and resistant to wear, making them ideal for industrial and decorative applications.

- Versatility: Laser engraving can be used on a wide range of metals, including steel, stainless steel, aluminum, brass, and copper.

- Speed: The process is much faster than hand engraving, making it suitable for large-scale production.

- Cost-Effective: Once the initial setup is done, laser engraving can be more affordable than other methods, especially for high-volume projects.

If you’re considering this technique, what industries benefit most from laser engraving on metal? It’s widely used in jewelry making, industrial manufacturing, automotive detailing, and custom artwork. The possibilities are truly endless!

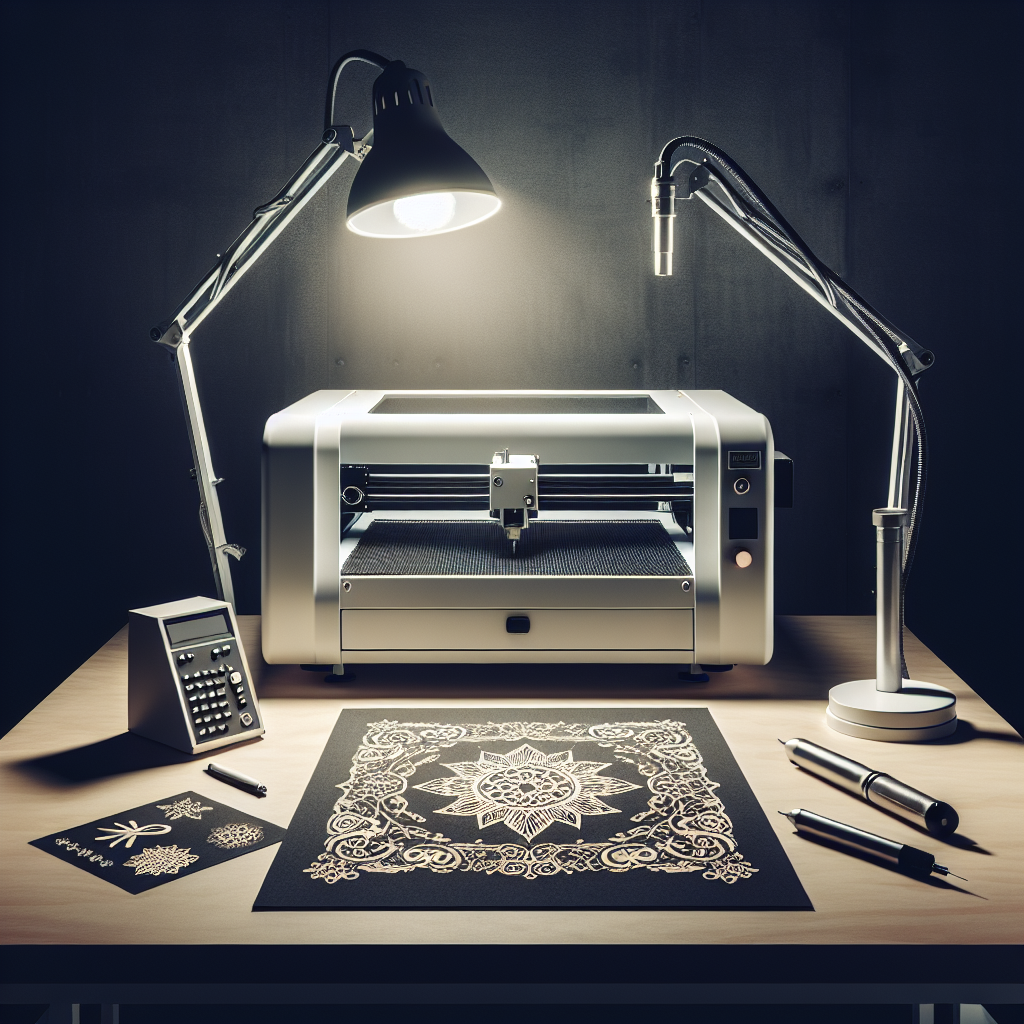

Essential Tools for Laser Engraving on Metal

To get started with laser engraving on metal, you’ll need the right equipment. One of the most popular tools for beginners is the . This machine is designed to be user-friendly while delivering professional-quality results.

Before purchasing any equipment, ask yourself, what factors should I consider when choosing a laser engraver? Key considerations include the power of the laser, the size of the work area, and the type of materials you plan to engrave. For metalwork, look for a machine with sufficient power to handle thicker or harder metals without overheating.

Selecting the Right Metal for Laser Engraving

Not all metals are created equal when it comes to laser engraving. Some materials are easier to work with than others, and understanding their properties can help you achieve better results. Here are some popular choices:

- Steel: Known for its durability, steel is a great option for industrial applications. However, it requires higher laser power due to its hardness.

- Stainless Steel: This material is widely used in jewelry and decorative items because of its resistance to corrosion and its ability to maintain sharp engravings.

- Aluminum: Aluminum is lightweight and easy to engrave, making it a favorite for custom signs and plaques.

- Brass: Brass offers a golden finish and is commonly used in decorative items like clocks and trophies.

- Copper: Copper is soft and conducts heat well, which makes it ideal for intricate designs. However, it tends to oxidize over time, so finishing is often required.

What about plated metals? While gold and silver plating can add a luxurious finish to your projects, they require careful handling to avoid damaging the coating during engraving.

Tips for Achieving Perfect Laser Engravings on Metal

To get the best results from your laser engraving projects, follow these tips:

- Preparation is Key: Clean the metal surface thoroughly before engraving to ensure optimal adhesion and clarity. Remove any dirt or oils that could interfere with the process.

- Test Your Settings: Always perform a test run on scrap material to adjust your laser power, speed, and focus settings. This helps prevent mistakes on your final piece.

- Use Proper Safety Gear: Laser engraving produces fumes and debris, so wear safety goggles, gloves, and a mask to protect yourself.

- Experiment with Design: Don’t be afraid to try different patterns, fonts, and depths. Software like CorelDRAW or Adobe Illustrator can help you create custom designs that bring your vision to life.

- Add Finishing Touches: After engraving, consider polishing or coating the metal to enhance its appearance and protect it from wear and tear.

Frequently Asked Questions About Laser Engraving on Metal

If you’re just starting out, here are some common questions and answers:

- Q: Can I engrave on any type of metal?

A: While most metals can be engraved with a laser, the results may vary depending on their hardness and thickness. Always test your materials first. - Q: How deep can a laser engraving go?

A: The depth depends on the power of your laser and the settings you use. With higher power, you can achieve deeper engravings suitable for industrial applications. - Q: Is laser engraving on metal environmentally friendly?

A: Compared to traditional methods that use chemicals or mechanical abrasion, laser engraving is cleaner and produces less waste. However, proper ventilation is still needed due to fumes generated during the process.

Conclusion

Laser engraving on metal is a versatile and powerful technique that opens up a world of creative possibilities. Whether you’re creating custom jewelry, industrial parts, or decorative items, this method offers precision, durability, and unmatched detail. With the right tools and techniques, you can achieve professional-quality results even as a beginner.

If you’re ready to take the plunge into laser engraving on metal, consider starting with a reliable machine like the . With practice and experimentation, you’ll soon be creating stunning works of art that showcase your skills. Happy engraving!