The Best Wood for Laser Cutter: A Comprehensive Guide

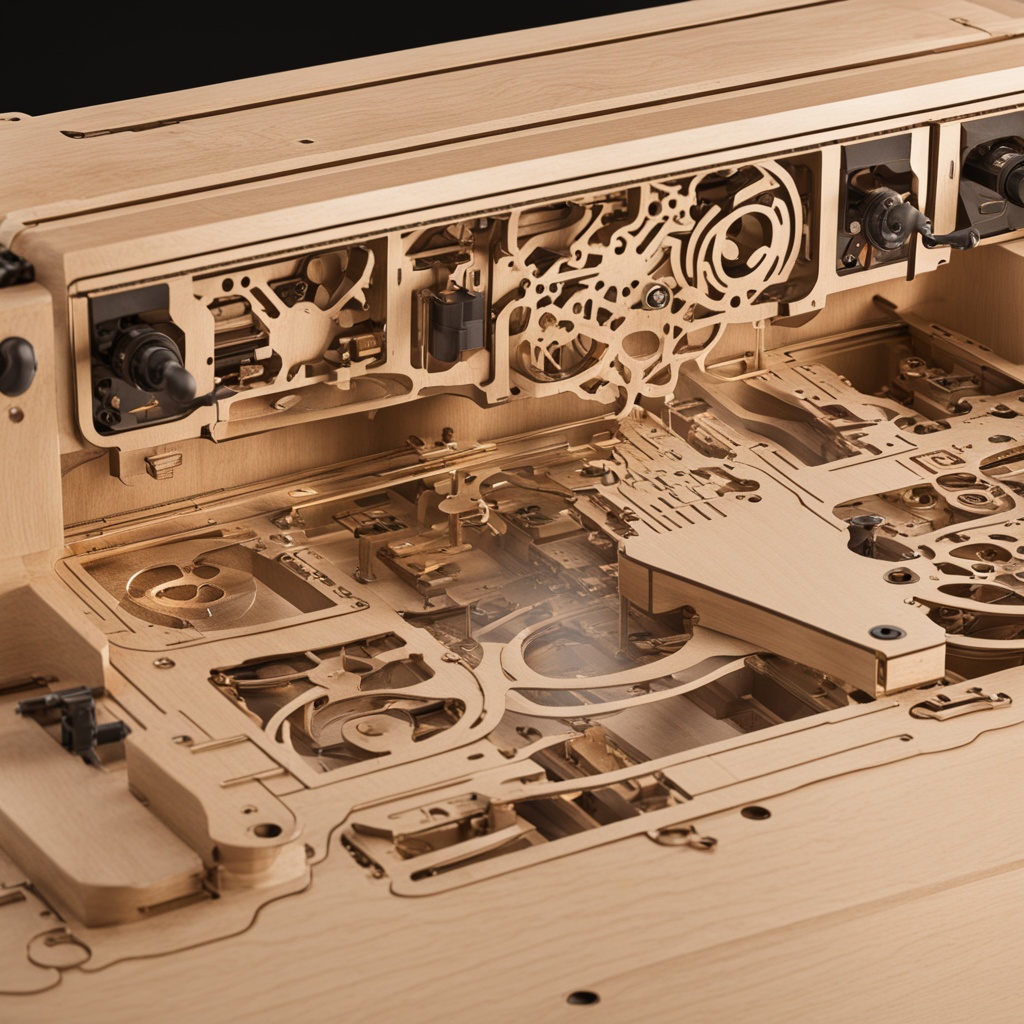

Laser cutting has become an indispensable tool in modern woodworking, offering precision, versatility, and creativity. Whether you’re crafting intricate designs, creating custom furniture, or producing decorative items, choosing the right wood is crucial for achieving professional results. In this guide, we’ll explore the best wood for laser cutter applications, discuss their properties, benefits, and considerations, and provide answers to common questions to help you make an informed decision.

Why Use Wood for Laser Cutting?

Laser cutting technology has revolutionized woodworking by enabling artists and craftsmen to create detailed and precise designs with ease. Unlike traditional cutting methods, laser cutting offers non-contact cutting, which minimizes material deformation and allows for intricate patterns and texturing. Additionally, wood is an ideal material for laser cutting due to its natural beauty, versatility, and ability to accept laser engraving, making it perfect for both functional and decorative projects.

Types of Wood Suitable for Laser Cutting

Not all woods are created equal when it comes to laser cutting. Some types perform better than others due to their density, grain structure, and moisture content. Below, we explore the most popular wood types for laser cutter applications:

- Maple Wood: Known for its fine texture and consistent grain, maple is a favorite among laser cutting enthusiasts. Its light color allows for vibrant engraving, making it ideal for decorative projects.

- Oak Wood: A durable and versatile choice, oak’s natural beauty and medium density make it suitable for both cutting and engraving. It’s perfect for furniture and home decor items.

- Birch Wood: Lightweight and easy to work with, birch is a great option for laser cutting due to its smooth surface and ability to hold detailed engravings.

- Plywood: A popular choice for laser cutting, plywood offers excellent stability and resistance to warping. It’s often used for creating signs, decorative panels, and 3D designs.

- Sycamore Wood: Similar to maple, sycamore has a fine grain and light color, making it ideal for laser engraving and cutting intricate designs.

- Mahogany Wood: Known for its rich color and durability, mahogany is a premium choice for high-quality laser-cut projects, such as furniture and musical instruments.

When selecting wood for laser cutter applications, it’s important to consider the material’s thickness, grain pattern, and moisture content. Proper preparation, such as sanding and drying, can also enhance the outcome of your project.

Benefits of Using Wood for Laser Cutting

Beyond its aesthetic appeal, wood offers several advantages when used with laser cutting technology:

- Precision and Detail: Lasers can cut and engrave intricate designs with exceptional accuracy, making it easier to create complex patterns and texturing.

- Versatility: Wood is compatible with a wide range of laser cutter models, allowing for endless creative possibilities. You can use the same material for cutting, engraving, or even 3D carving.

- Eco-friendliness: Wood is a renewable resource and biodegradable, making it an eco-friendly choice for sustainable projects.

- Affordability: Compared to other materials like metal or acrylic, wood is often more cost-effective, especially for small-scale or hobbyist projects.

Question: What type of wood do you prefer for laser cutting? Let us know in the comments below!

Considerations When Choosing Wood for Laser Cutter

While wood is an excellent material for laser cutting, there are several factors to keep in mind when selecting the right type:

- Density and Hardness: Denser woods like oak or mahogany may require more powerful lasers and slower cutting speeds compared to softer woods like birch or maple.

- Moisture Content: High moisture content in wood can lead to warping, cracking, or uneven laser cutting. Ensure the wood is properly dried and stored before use.

- Grain Pattern: Open-grained woods like oak may require additional sanding to achieve a smooth finish, while closed-grained woods like maple offer a more uniform surface.

- Color and Finish: Consider how the wood’s natural color and texture will complement your design. Some woods can be stained or painted post-laser cutting for added customization.

Question: Have you ever encountered challenges when working with certain types of wood? Share your experiences!

Tips for Working with Wood in Laser Cutting

To get the best results from your laser cutter, follow these tips:

- Preparation is Key: Always sand the wood surface to remove any rough spots or splinters. A smooth surface ensures cleaner cuts and engravings.

- Use the Right Settings: Adjust your laser cutter’s power, speed, and focus according to the type of wood you’re using. Experiment with different settings on scrap material before starting your final project.

- Ventilation is Essential: Laser cutting wood produces fumes and particulate matter. Ensure your workspace is well-ventilated or use a dust collection system to maintain air quality.

- Protect Your Workpiece: Place a sheet of cardboard or metal under the wood to catch laser debris and prevent damage to your work surface.

- Post-Cut Finishing: After cutting or engraving, sand the edges for a polished finish. You can also apply a protective coating like wax or oil to enhance durability.

Frequently Asked Questions About Wood and Laser Cutting

Laser cutting wood is a popular technique, but there are always questions that arise. Here are some answers to common inquiries:

- Q: Can I laser cut any type of wood?

A: While most types of wood can be laser cut, very dense or oily woods like teak may pose challenges and require specialized equipment. - Q: Does laser cutting damage the wood?

A: Laser cutting is a non-contact process, so it doesn’t physically damage the wood beyond the intended cuts. However, high-power lasers can char or discolor the material if not set properly. - Q: Can I engrave on any type of wood?

A: Yes, but softer woods like pine may require lower laser power to avoid burning. Hardwoods like maple and oak offer better results for detailed engravings. - Q: How thick can the wood be for laser cutting?

A: The maximum thickness depends on your laser cutter’s specifications. Most hobby-grade lasers can handle wood up to 20mm in thickness, while industrial-grade machines can cut much thicker materials.

Where to Find High-Quality Wood for Laser Cutting

If you’re looking for the best wood for laser cutter applications, consider purchasing from reputable suppliers who offer a variety of species and grades. Online marketplaces like Amazon, eBay, and specialized woodworking stores are great places to start your search. Additionally, many local lumberyards carry pre-cut and sanded wood sheets perfect for laser cutting projects.

Question: Where do you source your wood for laser cutting? Let us know!

Conclusion

Wood remains one of the most versatile and beautiful materials for laser cutting, offering endless creative possibilities. By understanding the properties of different wood types, preparing your material properly, and using the right techniques, you can achieve stunning results in your woodworking projects. Whether you’re a hobbyist or a professional craftsman, investing in high-quality wood is essential for producing polished and durable pieces.

Remember to experiment with various woods and settings to find what works best for your unique style and needs. Happy crafting!