The Art of Laser Engraving Stainless: Precision Meets Creativity

Laser engraving stainless steel has become a cornerstone of modern manufacturing and artistic expression. This cutting-edge technology allows for intricate designs, precise markings, and durable results that withstand the test of time. Whether you’re working in industries like jewelry, automotive, or aerospace, or simply looking to add a personal touch to your projects, laser engraving stainless steel offers unparalleled versatility and precision.

In this article, we’ll explore the world of , its applications, benefits, and how you can get started with this fascinating technology. Let’s dive in!

What is Laser Engraving Stainless Steel?

Laser engraving stainless steel involves the use of a high-powered laser to create permanent markings or designs on the surface of stainless steel materials. Unlike traditional methods like acid etching or mechanical engraving, laser engraving offers unmatched precision and flexibility. The laser beam heats and vaporizes the material, creating detailed patterns that are resistant to wear and tear.

This process is ideal for creating everything from logos and serial numbers to custom artwork and decorative elements. It’s no wonder that laser engraving stainless steel has become a go-to solution for industries requiring precision and durability.

Why Choose Laser Engraving Stainless Steel?

Laser engraving stainless steel offers numerous advantages over traditional methods:

- Precision: The laser beam can create intricate details with pinpoint accuracy, making it ideal for complex designs.

- Durability: Laser engravings are permanent and resistant to fading, ensuring long-lasting results.

- Versatility: It can be used on a wide range of stainless steel products, from small parts to large components.

- Efficiency: The process is fast and automated, reducing production time and costs.

These benefits make laser engraving stainless steel a preferred choice for industries ranging from healthcare to electronics.

Applications of Laser Engraving Stainless Steel

Laser engraving stainless steel is widely used in various industries due to its adaptability and precision. Here are some common applications:

- Jewelry Making: Custom engravings on rings, necklaces, and bracelets add a personal touch that customers love.

- Automotive Industry: Laser engraving is used to create vehicle identification numbers (VINs) and logos on parts.

- Aerospace: Precision engravings are essential for marking components in aircraft manufacturing.

- Medical Devices: Stainless steel medical instruments often require permanent, traceable markings for safety and regulation compliance.

- Art and Design: Artists use laser engraving to create stunning, intricate designs on stainless steel surfaces.

These applications highlight the versatility of laser engraving stainless steel in both industrial and creative settings.

Getting Started with Laser Engraving Stainless Steel

If you’re interested in laser engraving stainless steel, there are a few key steps to take:

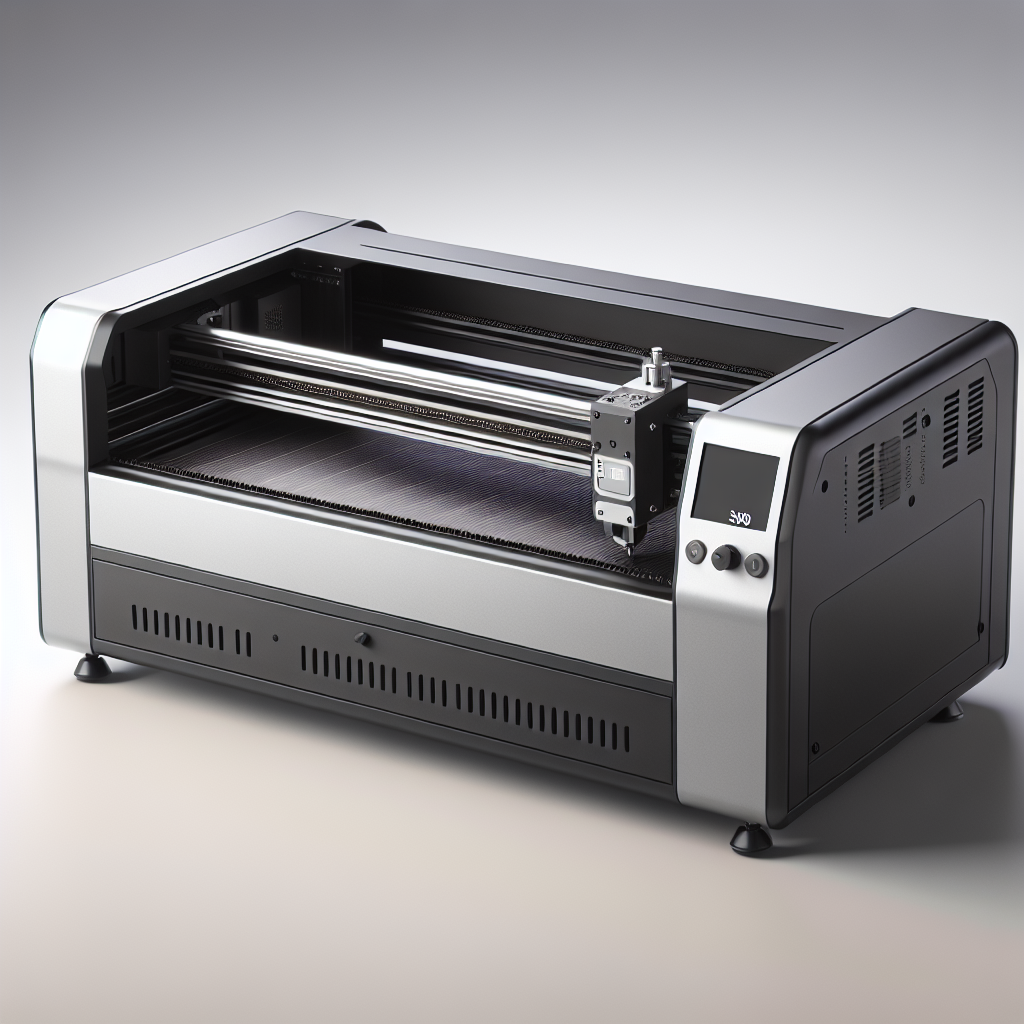

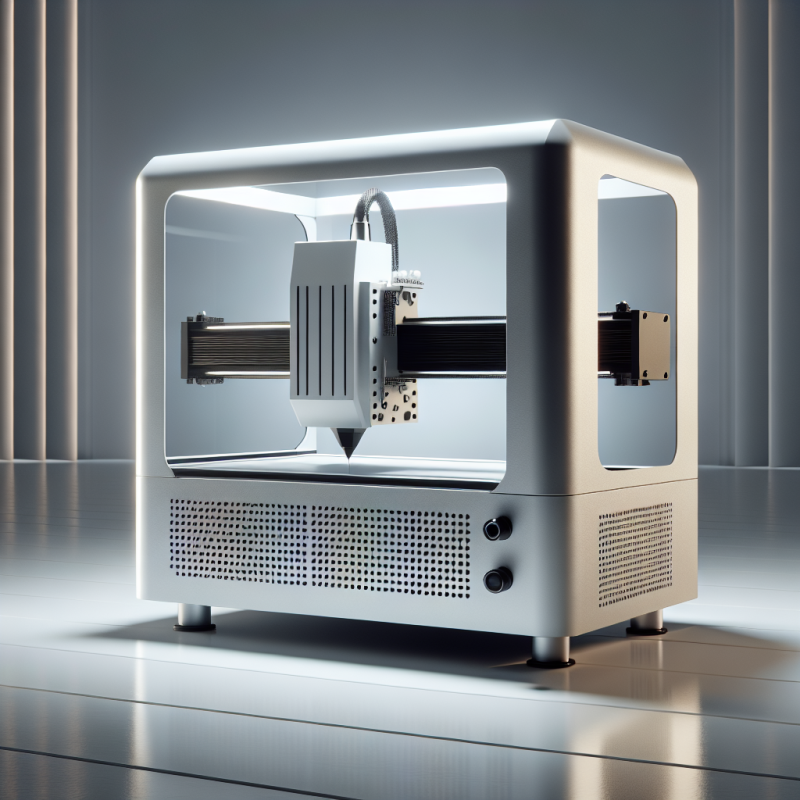

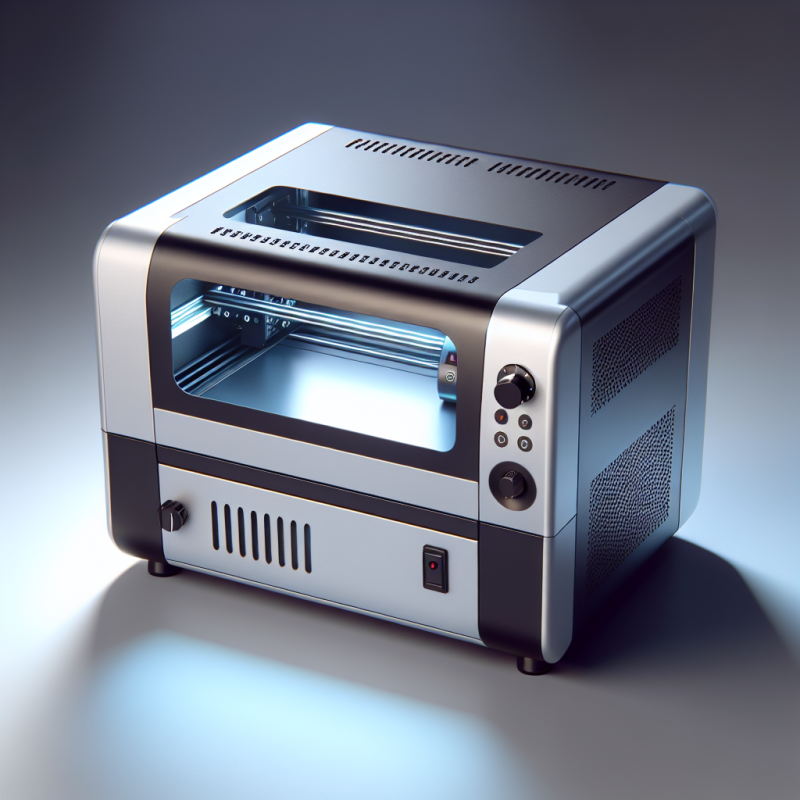

- Select the Right Equipment: Invest in a high-quality laser engraver designed for metal. Look for machines with adjustable power settings and advanced software for precise control. For example, the machine is a top choice for its versatility and performance.

- Design Your Project: Use CAD software to create your design or artwork. Ensure the design is compatible with your laser engraver’s capabilities.

- Prepare the Material

- Set Up the Laser Engraver: Follow the manufacturer’s instructions to calibrate your machine and adjust settings like power, speed, and focus.

- Start Engraving: Once everything is set up, load your design into the software and begin engraving. Monitor the process to ensure accuracy and quality.

: Clean and polish the stainless steel surface to ensure optimal results. Remove any dirt or grease that could interfere with the engraving process.

With these steps in place, you can start creating stunning laser engravings on stainless steel with ease.

Tips for Achieving Perfect Laser Engravings

To get the best results from your laser engraving stainless steel projects, consider the following tips:

- Choose the Right Power Setting: Too much power can damage the material, while too little may result in shallow engravings. Experiment with different settings to find the optimal level for your project.

- Use Proper Focus: Ensure the laser beam is focused properly on the surface of the stainless steel for sharp and precise engravings.

- Test Your Design: Always test your design on a scrap piece of stainless steel before engraving it on your final project. This allows you to make adjustments without wasting materials.

- Work in a Well-Ventilated Area: Laser engraving produces fumes and particulate matter, so ensure good ventilation to protect yourself and the environment.

By following these tips, you can achieve professional-quality laser engravings on stainless steel every time.

Frequently Asked Questions

If you’re new to laser engraving stainless steel, here are answers to some common questions:

- Is laser engraving stainless steel safe?

Yes, but it’s important to follow safety guidelines. Wear protective eyewear and work in a well-ventilated area to avoid inhaling fumes. - Can I engrave on any type of stainless steel?

Most types of stainless steel can be laser engraved, but the process may vary depending on the material’s thickness and finish. Always test on a small sample first. - How deep can the engravings be?

The depth depends on the power and duration of the laser beam. Higher power settings or longer exposure times will create deeper engravings.

These answers should help you feel more confident about starting your laser engraving stainless steel projects.

Conclusion

Laser engraving stainless steel is a powerful and versatile technique that has revolutionized industries ranging from jewelry making to aerospace. Its precision, durability, and adaptability make it an ideal choice for creating custom designs and markings on stainless steel surfaces.

If you’re looking to invest in laser engraving equipment, consider the machine. With its advanced features and reliable performance, it’s a great choice for both beginners and professionals.

So why wait? Start exploring the possibilities of laser engraving stainless steel today and bring your creative visions to life!