CO2 Laser Cutter: A Comprehensive Guide to Precision Cutting

When it comes to precision cutting and engraving, few tools can rival the capabilities of a CO2 laser cutter. This versatile machine has become an indispensable tool in various industries, from woodworking and metalworking to sign-making and electronics manufacturing. Whether you’re a hobbyist or a professional, understanding the intricacies of a CO2 laser cutter can open up a world of creative possibilities. In this article, we’ll explore everything you need to know about CO2 laser cutters, including their benefits, applications, and how to choose the right one for your needs.

What is a CO2 Laser Cutter?

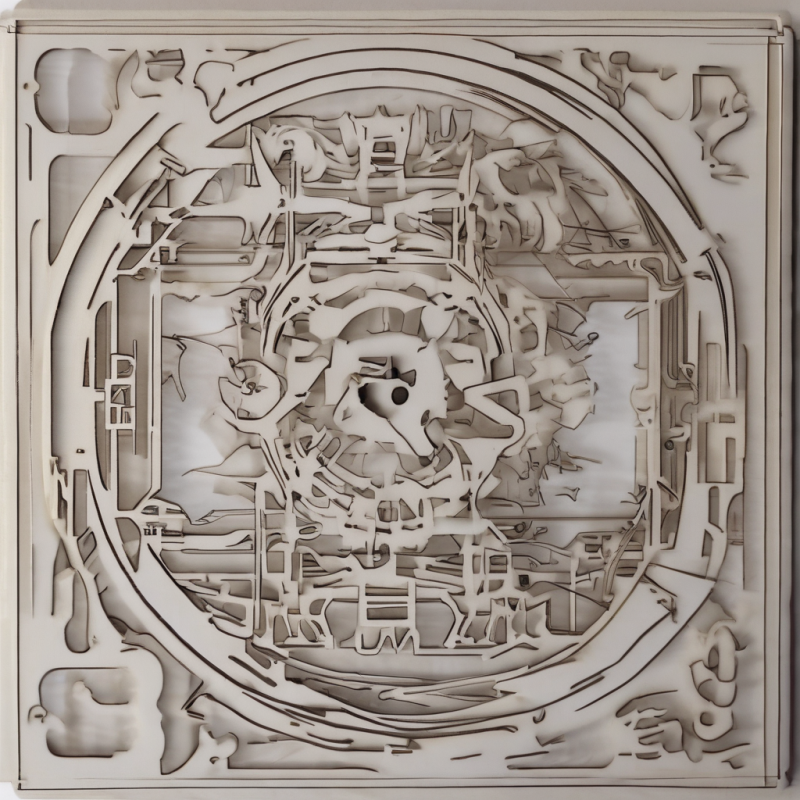

A CO2 laser cutter is a machine that uses a laser beam generated by a carbon dioxide (CO2) gas-filled tube. The laser is directed through mirrors and focused onto a workpiece to cut, engrave, or etch materials with high precision. Unlike traditional cutting methods, a CO2 laser cutter offers unparalleled accuracy, speed, and versatility. It can handle a wide range of materials, including wood, acrylic, metal, glass, and plastic.

The process involves creating a design on a computer-aided design (CAD) software or importing it from another program. The design is then sent to the laser cutter, which reads the instructions and executes the cuts with precision. This makes it an ideal tool for both small-scale projects and large-scale production runs.

Benefits of Using a CO2 Laser Cutter

There are numerous reasons why CO2 laser cutters have become so popular in recent years. Here are some of the key benefits:

- Precision and Accuracy: A CO2 laser cutter can achieve cuts with a tolerance of less than 0.001 inches, making it ideal for intricate designs and complex patterns.

- Versatility: It can cut through a wide variety of materials, allowing you to work on different projects without needing multiple tools.

- Speed: Compared to traditional cutting methods, a CO2 laser cutter is much faster, reducing production time and increasing efficiency.

- Low Maintenance: With proper care, a CO2 laser cutter can last for years without requiring frequent repairs or replacements.

- Eco-Friendly: It produces minimal waste compared to other cutting methods, making it an environmentally friendly option.

These benefits make a CO2 laser cutter a must-have tool for anyone looking to enhance their productivity and creativity. But how do you choose the right one? Let’s dive deeper into its applications and uses.

Applications of CO2 Laser Cutters

CO2 laser cutters are used in a variety of industries due to their versatility and precision. Here are some common applications:

- Woodworking: Cutting intricate designs, patterns, and shapes on wood for furniture, decorative items, and signage.

- Metalworking: Engraving and cutting metals like steel, aluminum, and stainless steel for industrial parts and components.

- Sign Making: Creating custom signs with precise lettering and graphics on materials like acrylic and metal.

- Fabrication: Prototyping and producing small batches of parts for electronics, automotive, and aerospace industries.

- Crafts and Artwork: Engraving intricate designs on materials like glass, stone, and leather for custom art pieces.

The possibilities are endless with a CO2 laser cutter. Whether you’re working on a small project or large-scale production, this tool can handle it all with ease. But how does it compare to other types of lasers?

How Does a CO2 Laser Cutter Compare to Other Lasers?

While CO2 laser cutters are highly versatile, they do have limitations compared to other types of lasers. For example:

- Fiber Lasers: These are more powerful and can handle thicker materials than a CO2 laser cutter. However, they are also more expensive and require more advanced cooling systems.

- Diode Lasers: These are smaller and more compact but lack the cutting power of a CO2 laser cutter for heavy-duty applications.

Despite these limitations, a CO2 laser cutter remains one of the most popular choices for general-purpose cutting and engraving due to its balance of cost, performance, and versatility.

Choosing the Right CO2 Laser Cutter

If you’re in the market for a CO2 laser cutter, there are several factors to consider:

- Material Thickness: Determine the maximum thickness of the materials you’ll be cutting. This will help you choose a machine with sufficient power and beam quality.

- Cutting Speed: Consider how quickly you need to complete your projects. Higher-powered machines can cut through materials faster but may come at a higher cost.

- Budget: Decide on your budget and compare different models within that range. Look for features like build quality, software compatibility, and customer support.

- Software Compatibility: Ensure the machine is compatible with the CAD software you plan to use. Many modern CO2 laser cutters come with user-friendly interfaces and intuitive controls.

By carefully evaluating these factors, you can find a CO2 laser cutter that meets your needs and fits within your budget. Remember, investing in a high-quality machine will pay off in the long run by providing years of reliable service and superior results.

Maintenance Tips for Your CO2 Laser Cutter

To ensure your CO2 laser cutter performs optimally, regular maintenance is essential. Here are some tips to keep your machine running smoothly:

- Clean the Optics: Regularly clean the mirrors and lenses to prevent dust and debris from interfering with the laser beam.

- Check Gas Levels: Ensure the CO2 gas levels are adequate and replace them as needed. Low gas pressure can reduce cutting performance.

- Lubricate Moving Parts: Keep all moving parts lubricated to prevent wear and tear. This includes the gantry, rails, and stepper motors.

- Update Software: Stay up-to-date with software updates to ensure your machine is running the latest firmware and features.

- Inspect for Damage: Regularly inspect the machine for any signs of damage or wear, such as cracked lenses or worn belts. Address issues promptly to avoid costly repairs down the line.

By following these maintenance tips, you can extend the lifespan of your CO2 laser cutter and maintain its performance over time. Remember, a well-maintained machine is more efficient, reliable, and safer to operate.

Frequently Asked Questions About CO2 Laser Cutters

If you’re new to CO2 laser cutters, you might have some questions. Here are answers to some of the most common ones:

- Q: Can a CO2 laser cutter cut through metal?

- A: Yes, but it depends on the thickness and type of metal. A CO2 laser cutter can handle thin to medium-thickness metals like steel, aluminum, and stainless steel.

- Q: Is a CO2 laser cutter safe to use?

- A: Yes, as long as you follow proper safety guidelines. Always wear protective eyewear and ensure the machine is properly ventilated to avoid inhaling fumes from cutting materials.

- Q: How expensive is a CO2 laser cutter?

- A: Prices vary depending on the model, power, and features. Entry-level machines can cost around $1,000, while high-end models can exceed $10,000.

- Q: Can I use a CO2 laser cutter for woodworking?

- A: Yes! Many woodworkers use CO2 laser cutters to create intricate designs and patterns on wooden surfaces. The laser cuts cleanly without burning the material.

These answers should give you a better understanding of what to expect when using a CO2 laser cutter. If you have more questions, consult your machine’s manual or contact the manufacturer for assistance.

The Future of CO2 Laser Cutting

As technology continues to advance, so does the field of laser cutting. The future looks promising for CO2 laser cutters, with innovations in beam quality, automation, and software integration expected to enhance their performance even further. With these advancements, we can expect CO2 laser cutters to remain a staple tool in workshops, fabrication shops, and hobbyist garages alike.

If you’re ready to take the plunge into the world of laser cutting, a CO2 laser cutter is an excellent choice for its versatility, affordability, and ease of use. With proper care and maintenance, this machine will serve you well for years to come, helping you bring your creative visions to life with precision and efficiency.

Happy cutting!