Double Color Acrylic for Laser Engraving

Laser Engraving Technology and Applications

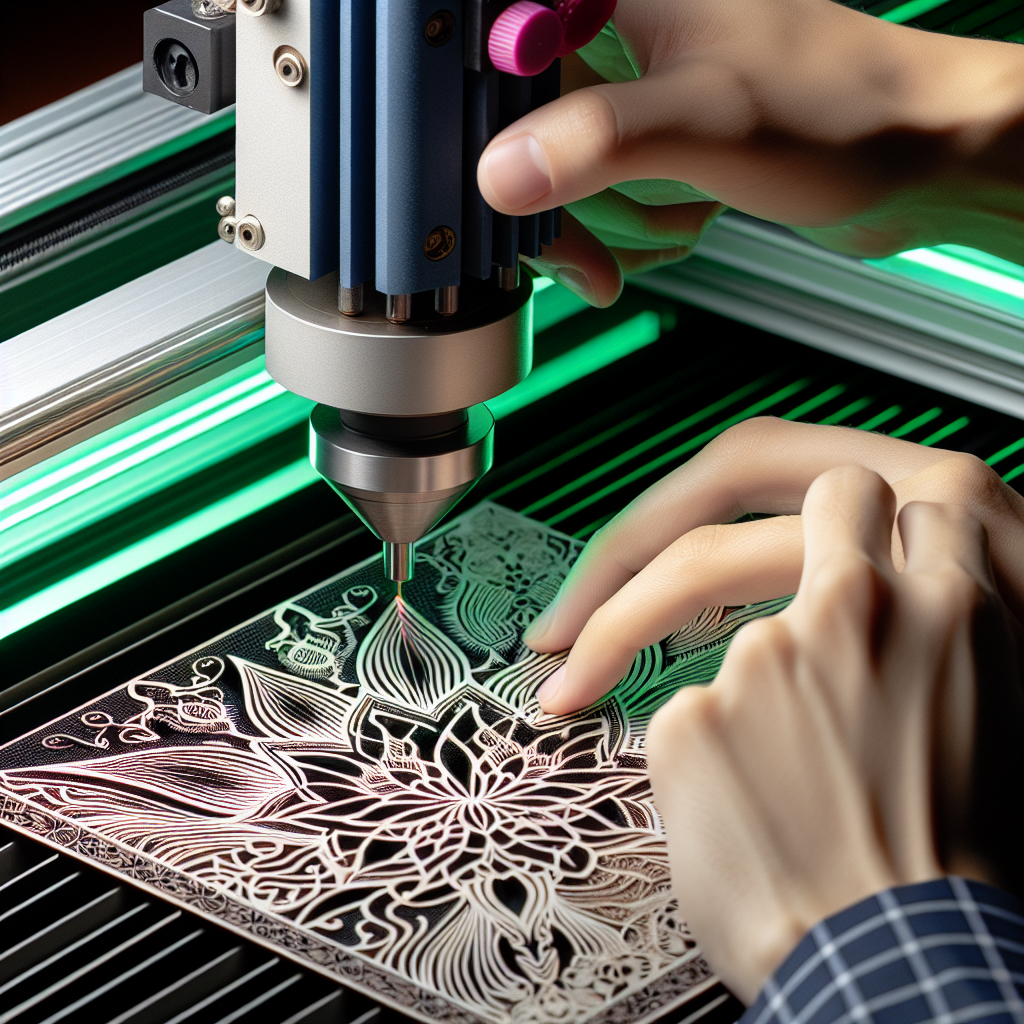

Laser engraving technology has revolutionized the way we create intricate designs and patterns on various materials, including double color acrylic. This advanced technique involves using a high-intensity laser beam to vaporize the surface of the material, revealing the contrasting layer beneath. The result is a stunning, permanent, and precise image or text.

Double color acrylic, specifically, offers a unique challenge and opportunity for laser engravers. This material consists of two layers of acrylic with different colors, allowing for striking visual effects when engraved. The outer layer can be any color, while the inner layer typically contrasts sharply for maximum impact. This combination makes double color acrylic ideal for a wide range of applications, from signage and awards to personalized gifts and decorative items.

The versatility of laser engraving on double color acrylic is unparalleled. From simple text and logos to complex images and patterns, the possibilities are endless. This technology is particularly suited for creating intricate details and fine lines, which would be difficult or impossible to achieve with traditional methods.

Machine Specifications and Features

When choosing a laser engraver for double color acrylic, it’s crucial to consider the machine’s specifications and features. A high-quality laser engraver, such as the XTool Laser Engraver, offers several key advantages:

- Precision and Accuracy: Advanced laser engravers utilize high-precision stepper motors and optical systems to ensure accuracy down to microns. This level of precision is essential for creating clean, sharp lines and intricate details on double color acrylic.

- Power and Speed: The laser beam’s power and the machine’s engraving speed are critical factors. A more powerful laser can vaporize material more quickly, while adjustable speed settings allow for greater control over the depth and appearance of the engraving.

- Software Compatibility: Look for a laser engraver that is compatible with industry-standard design software, such as Adobe Illustrator or CorelDRAW. This will enable you to import and edit your designs easily before sending them to the machine.

- Bed Size and Workspace: The size of the engraving bed determines the maximum workpiece dimensions. Ensure the machine you choose can accommodate your largest pieces of double color acrylic.

- Safety Features: Safety should always be a top priority. Look for features such as emergency stop buttons, enclosed workspaces, and laser safety glasses to protect operators from harm.

Material Compatibility

Double color acrylic is highly compatible with laser engraving machines. However, it’s essential to understand the material’s properties and how they interact with the laser beam. The outer layer’s thickness, color, and material composition can affect the engraving process. For instance, darker colors may absorb more laser energy, resulting in faster engraving speeds and deeper cuts.

It’s also important to note that double color acrylic can have different melting points for the two layers. This can create challenges during the engraving process, as the laser may need to be adjusted to avoid melting or deforming the inner layer. Testing with scrap pieces of material is always recommended to dial in the perfect settings for your project.

Safety Considerations

Safety is paramount when working with laser engraving machines. The intense laser beam can cause serious eye and skin injuries if not handled properly. Here are some essential safety tips:

- Wear Laser Safety Glasses: Always wear approved laser safety glasses when operating the machine or handling laser-engraved materials.

- Use an Enclosed Workspace: Ensure the laser engraver is used in an enclosed workspace to prevent laser radiation from escaping and harming bystanders.

- Follow Manufacturer Instructions: Read and follow the machine’s operator manual carefully. Understand all warning signs and emergency stop procedures.

- Ventilation: Ensure adequate ventilation to prevent the accumulation of harmful fumes and particles generated during the laser engraving process.

- Regular Maintenance: Keep the machine clean and well-maintained to reduce the risk of malfunctions or accidents.

Industry Best Practices

To get the best results when laser engraving double color acrylic, follow these industry best practices:

- Design Optimization: Use vector graphics with clean, simple lines for the best results. Avoid using raster images, as they can result in pixelated or blurred engravings.

- Material Preparation: Ensure the double color acrylic is clean and free of dust, debris, or protective films before engraving. Use a lint-free cloth and mild cleaner if necessary.

- Test Cuts: Always perform test cuts on scrap material to determine the optimal laser settings for your project. Adjust power, speed, and focal distance as needed.

- Layer Management: Be aware of the melting points of the two acrylic layers. Adjust the laser settings to avoid melting the inner layer and ruining your design.

- Post-Processing: Consider post-processing steps such as cleaning and polishing to enhance the finished appearance of your engraved pieces.

Cost-Benefit Analysis

Investing in a high-quality laser engraver for double color acrylic can offer significant cost benefits. While the initial purchase price may be higher than traditional engraving methods, the long-term savings and increased productivity more than justify the investment. Here are some key benefits:

- Efficiency: Laser engraving is much faster than manual methods, allowing you to produce more pieces in less time.

- Precision: The high level of precision and detail achievable with laser engraving can increase the perceived value of your products.

- Versatility: A laser engraver can be used for a wide range of materials and applications, making it a versatile addition to your workshop.

- Scalability: As your business grows, you can easily scale up your laser engraving capabilities without significant additional investment.

Maintenance Tips

Proper maintenance is essential for keeping your laser engraver in top condition and ensuring long-term reliability. Here are some maintenance tips:

- Clean the Lens: Regularly clean the laser lens with a lint-free cloth and lens cleaner to prevent dust and debris from affecting the beam quality.

- Lubricate Moving Parts: Use approved lubricants to keep moving parts, such as stepper motors and guide rails, running smoothly.

- Check Belt Tension: Ensure the belts are properly tensioned to prevent slippage and maintain precision.

- Inspect Ventilation:

Keep the ventilation system clean and free of obstructions to prevent overheating and ensure safe operation.

Project Ideas and Tutorials

To inspire your creativity and help you get started with laser engraving double color acrylic, here are some project ideas and tutorials:

- Custom Signage: Create unique and eye-catching signs for your business or home using double color acrylic. Engrave text and graphics for a professional look.

- Personalized Gifts: Make personalized gifts for friends and family by engraving their names, initials, or a special message on double color acrylic keychains, coasters, or ornaments.

- Decorative Art:

Explore the artistic possibilities of laser engraving by creating intricate patterns and designs on double color acrylic panels for wall art or tabletop displays.