Exploring the Capabilities of Laser Cutter Engraving Machines

Have you ever wondered how precision and creativity come together in modern manufacturing? The laser cutter engraving machine stands as a testament to technological innovation, enabling intricate designs and precise cuts on various materials. This article delves into its functionalities, benefits, applications, and more, providing a comprehensive overview of this essential tool.

What is a Laser Cutter Engraving Machine?

A laser cutter engraving machine is a versatile device that uses focused laser beams to cut or engrave materials with exceptional precision. Unlike traditional methods, it offers non-contact processing, reducing material deformation and enhancing finish quality. The machine operates on the principle of directing high-powered lasers through optics to achieve desired cuts or engravings.

How does it differ from traditional cutting methods? The laser cutter’s precision and adaptability make it ideal for various industries, from metal fabrication to artistry. Its ability to handle multiple materials and produce intricate designs sets it apart as a valuable tool in modern workshops.

Benefits of Using a Laser Cutter Engraving Machine

Embracing a laser cutter engraving machine brings numerous advantages:

- Precision Cutting: Achieve accurate cuts with minimal material waste, ideal for detailed projects.

- Versatility: Capable of working on metals, plastics, wood, and glass, making it suitable for diverse applications.

- Speed: Efficient processing speeds reduce production time while maintaining quality.

- Cost-Effective: Low operational costs due to reduced material waste and energy efficiency.

- Clean Finish: Non-contact process ensures no mechanical stress, resulting in polished edges.

Applications of Laser Cutter Engraving Machines

The applications are vast and varied, spanning industries such as:

- Metal Fabrication: Precision cutting for automotive parts or metal art.

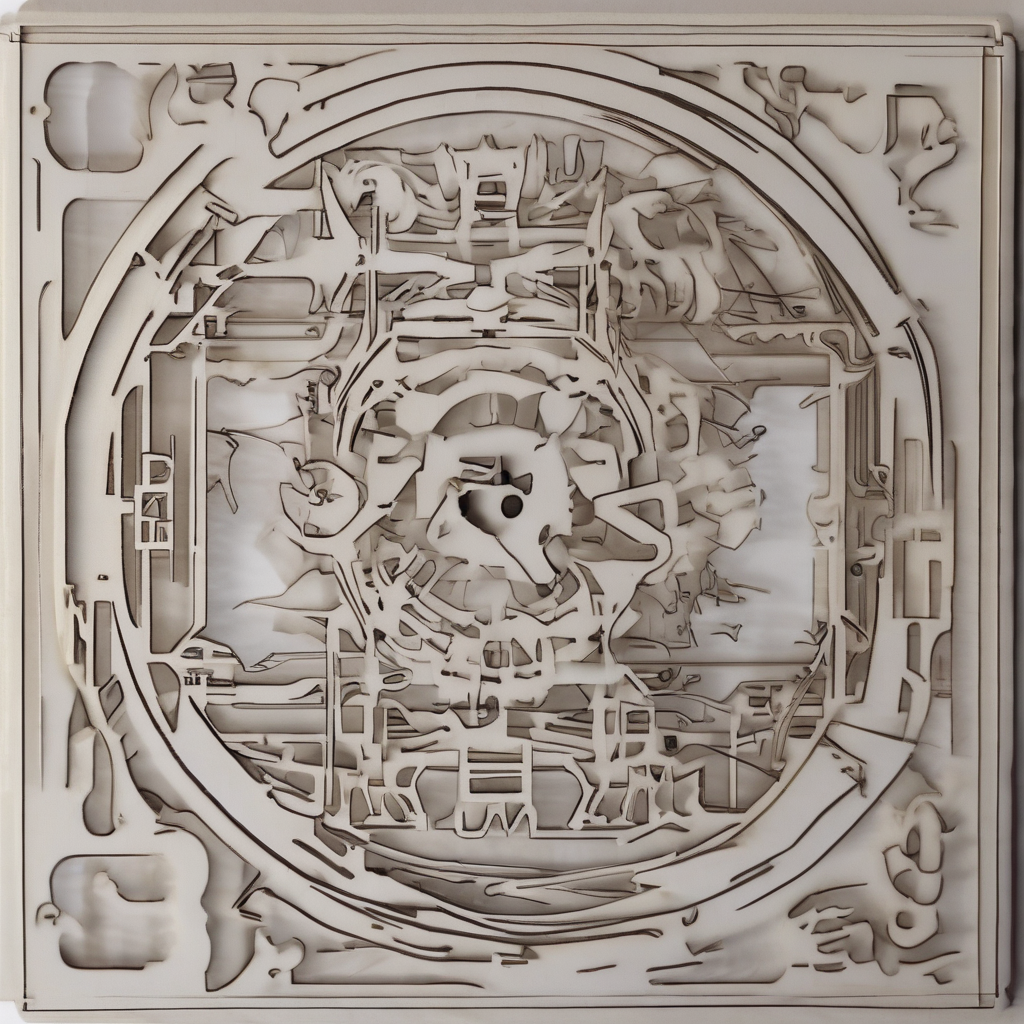

- Crafts: Creating custom engravings on jewelry or decorative items.

- Signage: Producing high-quality signs and displays with detailed text and graphics.

- Furniture: Engraving intricate designs on wooden furniture pieces.

How can it benefit your project? Whether you’re in manufacturing, arts, or signage, this machine offers precision and versatility that traditional methods struggle to match.

How Does a Laser Cutter Engraving Machine Work?

The process involves:

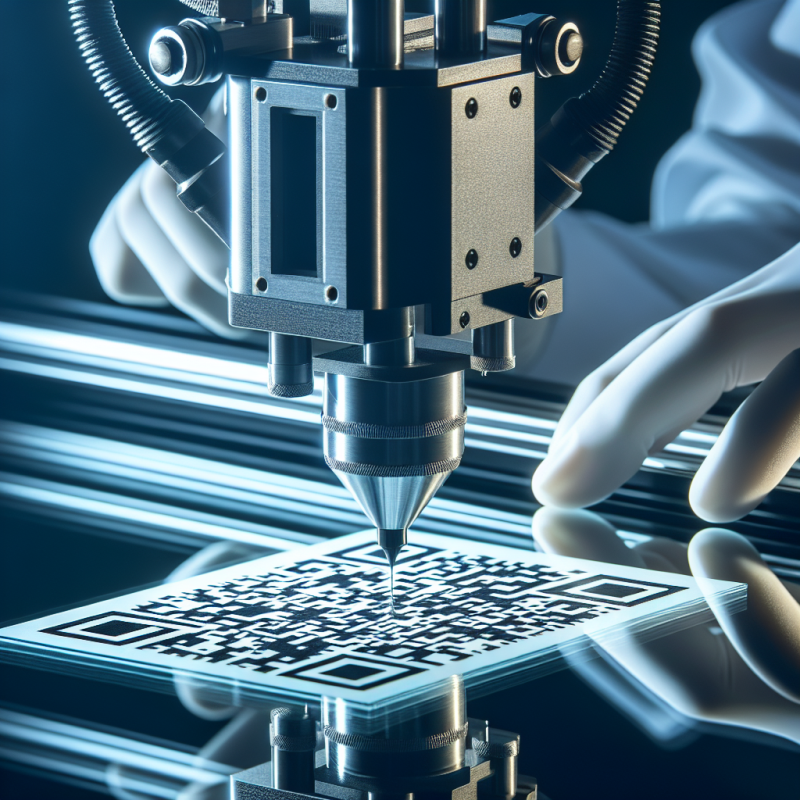

- Laser Generation: Producing a high-powered laser beam from sources like CO₂ or fiber lasers.

- Focusing the Beam: Using mirrors and lenses to concentrate the beam for precise cutting.

- Movement Control: Utilizing CNC (Computer Numerical Control) systems for accurate positioning, enabling complex designs.

- Cutting/Engraving: The focused laser heats and vaporizes material along programmed paths, creating cuts or engravings with micron-level precision.

What materials can it handle? Most models accommodate metals, plastics, wood, and glass, offering flexibility across projects.

Choosing the Right Laser Cutter Engraving Machine

Selecting the appropriate machine involves considering:

- Type of Material: Determine compatibility with your project materials (metal, plastic, etc.).

- Budget: Balance cost and features to suit your needs without overspending.

- Cutting Capacity: Assess the machine’s maximum cutting thickness for your applications.

- Add-On Features: Look for options like dust extraction systems or multi-head configurations for added functionality.

Why invest in one? Enhance productivity, precision, and versatility in your projects with this innovative tool.

Maintenance Tips for Laser Cutter Engraving Machines

To ensure longevity and optimal performance:

- Regular Cleaning: Keep optics and surfaces clean to prevent dust buildup affecting laser efficiency.

- Lens Care: Use lens cleaner regularly, as dirty lenses can scatter the beam, reducing cutting power.

- Firmware Updates: Stay updated with software upgrades for enhanced performance and features.

- Air Filtration: Maintain a clean working environment to prevent dust accumulation inside the machine.

How often should maintenance be performed? Regular checks, ideally every 3-6 months, ensure smooth operation and extend machine life.

Conclusion

The laser cutter engraving machine is a transformative tool for precision and creativity. Its versatility across materials and applications makes it indispensable in various industries. By understanding its benefits, functionality, and maintenance requirements, you can unlock new possibilities in your projects.

Ready to elevate your work? Consider integrating this cutting-edge technology into your processes today! For more details, explore the laser cutter engraving machine at [Your Link].