Exploring the World of Glass Laser Engraving Machines: Precision and Artistry Combined

Have you ever wondered how intricate designs are etched onto glass products with such precision? The answer lies in glass laser engraving machines, which combine cutting-edge technology with artistic creativity. These machines have revolutionized industries like jewelry, home decor, and even advertising by allowing for detailed and durable engravings on glass surfaces. If you’re curious about how this works or considering investing in one of these devices, read on to discover everything you need to know.

How Glass Laser Engraving Works

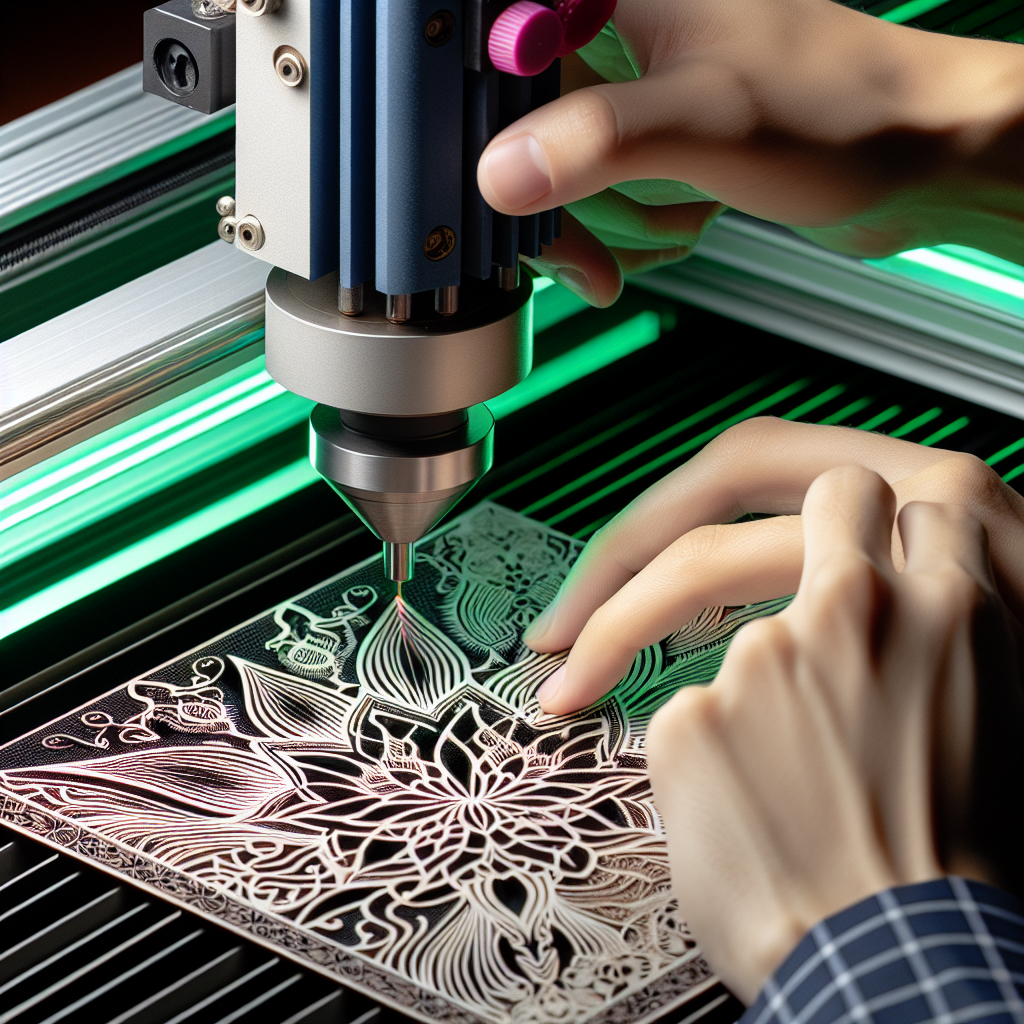

Laser engraving machines use a focused beam of light to create designs on various materials, including glass. Unlike traditional methods that rely on mechanical cutting or acid etching, laser engraving offers unparalleled precision and versatility. The machine emits a high-energy laser pulse that removes material from the surface, creating permanent markings without causing damage to the surrounding area.

The process begins with designing the desired pattern using specialized software. This design is then uploaded to the machine, which translates it into precise movements of the laser beam. The key advantage here is that even complex designs can be reproduced accurately every time, making it ideal for both small-scale and large-scale production.

Key features of glass laser engraving machines:

- High precision with minimal material waste

- Ability to work on curved or flat surfaces

- Durable and permanent engravings

- Quick setup and operation time

Advantages Over Traditional Methods

Compared to traditional engraving techniques, laser machines offer several advantages. For instance, they eliminate the need for hazardous chemicals like acids, making them a safer and more environmentally friendly option. Additionally, the non-contact nature of laser engraving reduces the risk of damaging delicate materials, such as thin glassware or fragile decorative pieces.

Another significant benefit is the ability to create highly detailed designs that would be impossible with manual methods. Whether you’re working on a custom logo for a wine bottle or adding personal engravings to wedding gifts, these machines deliver consistent results every time. Furthermore, they are more cost-effective in the long run due to reduced material waste and faster production times.

Applications of Glass Laser Engraving

The applications of glass laser engraving machines are vast and varied. Some common uses include:

- Customizing home decor items: From vases to windows, adding personalized designs enhances the aesthetic appeal of any space.

- Jewelry production: Engraving intricate patterns on glass beads or pendants for unique pieces.

- Advertising and branding: Etching logos onto promotional products like glasses, mugs, or bottles to increase brand visibility.

- Artistic expression: Creating fine art pieces with highly detailed engravings that showcase the artist’s creativity.

Are you considering using a glass laser engraving machine for your business? Let’s explore how to choose the right one for your needs!

Choosing the Right Glass Laser Engraving Machine

Selecting the appropriate machine depends on several factors, including the scale of your operations and the type of projects you undertake. For instance, if you’re a small-scale artisan, you might opt for a compact desktop model, while larger businesses may require industrial-grade machines capable of handling high-volume production.

Some key considerations to keep in mind:

- Laser power: Higher wattage lasers are better suited for thicker or more durable materials.

- Precision and resolution: Look for machines with high DPI (dots per inch) capabilities to ensure sharp and detailed engravings.

- Ease of use: User-friendly interfaces and intuitive software make the learning curve less steep, especially for beginners.

If you’re ready to take the plunge, consider checking out the [Best Glass Laser Engraving Machine](https://example.com) designed for both professionals and hobbyists. It offers a perfect balance of performance and affordability, making it an excellent choice for small to medium-sized projects.

Maintenance and Safety Tips

Like any precision tool, glass laser engraving machines require proper maintenance to ensure optimal performance. Regular cleaning of the optics and lenses is essential to prevent dust or debris from affecting the laser beam’s accuracy. Additionally, calibrating the machine periodically will help maintain consistent results over time.

Safety should always be a priority when working with lasers. Always wear protective eyewear and operate the machine in a well-ventilated area to avoid inhaling any fumes generated during the engraving process. Keeping your workspace clean and clutter-free also minimizes the risk of accidents.

Conclusion

Glass laser engraving machines have opened up new possibilities for creativity and efficiency across various industries. Whether you’re looking to start a small business, enhance your artistic skills, or simply add a personal touch to everyday items, these machines offer an unparalleled level of precision and versatility. By investing in one of these devices, you can unlock your full creative potential while staying ahead of the competition.

If you’re ready to dive into the world of laser engraving, why not explore the [Best Glass Laser Engraving Machine](https://example.com) today? With its advanced features and user-friendly design, it’s sure to become an indispensable tool in your workshop or studio!

Frequently Asked Questions

Q: Can I use this machine for both glass and other materials?

A: Yes! Many laser engraving machines are versatile enough to work on various materials, including wood, metal, and plastic, in addition to glass. Just ensure that the settings are adjusted appropriately for each material type.

Q: How long does it take to learn how to use a glass laser engraving machine?

A: With user-friendly software and intuitive controls, most users can become proficient within a few hours of practice. Start with simple designs and gradually work your way up to more complex projects as you gain confidence.

Q: Are these machines suitable for home use?

A: Absolutely! Compact desktop models are perfect for hobbyists or small-scale operations, making them ideal for home-based businesses or personal creative projects. Just ensure that your workspace is properly ventilated and equipped with safety measures.