Laser Branch Cutter Laser Engraving Machines

Laser engraving technology has revolutionized the way we create intricate designs and patterns on various materials. Among the diverse range of laser engraving machines available, the laser branch cutter stands out for its precision, versatility, and ease of use. This article delves into the intricacies of laser engraving technology, focusing specifically on the applications, specifications, material compatibility, safety considerations, industry best practices, cost-benefit analysis, maintenance tips, and project ideas associated with laser branch cutter laser engraving machines.

Laser Engraving Technology and Applications

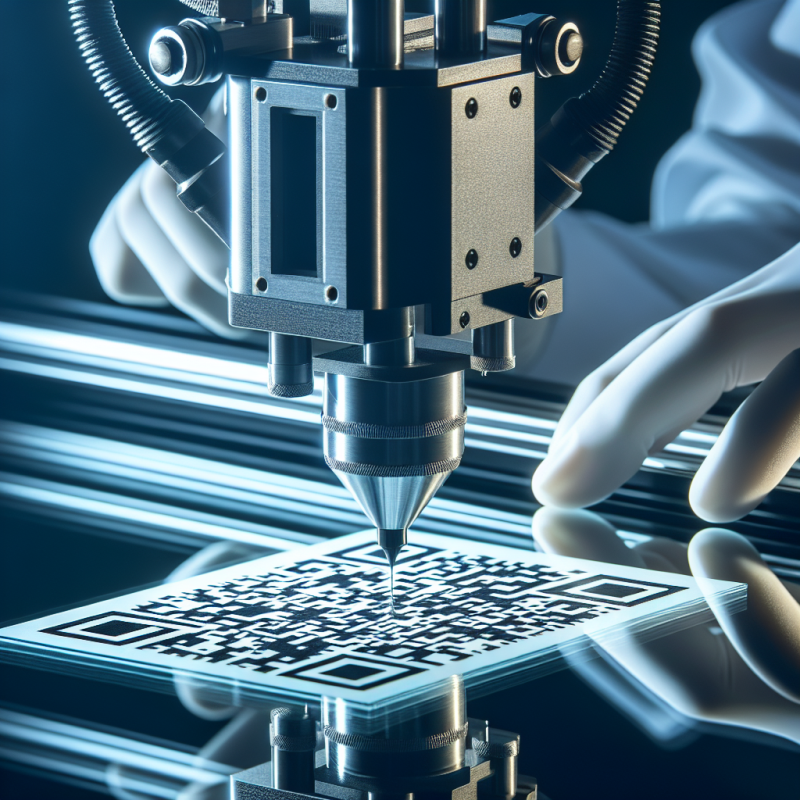

Laser engraving technology employs high-energy laser beams to create permanent marks or designs on surfaces. The process involves focusing the laser beam onto the material, causing localized heating that vaporizes or alters the material’s surface. This non-contact method offers several advantages, including precision, speed, and the ability to engrave complex designs.

Laser branch cutters are particularly suited for a wide range of applications. From personalized gifts and jewelry to industrial prototyping and signage, these machines can create stunning results on a variety of materials. Here are some notable applications:

- Personalized Gifts and Jewelry: Engrave names, dates, or intricate patterns on jewelry, phone cases, and other personalized items.

- Industrial Prototyping: Create detailed prototypes and models for product development.

- Signage and Branding: Produce high-quality signs, logos, and branding elements for businesses.

- Art and Craft: Explore your creativity by engraving intricate designs on wood, leather, and other materials for artistic projects.

Machine Specifications and Features

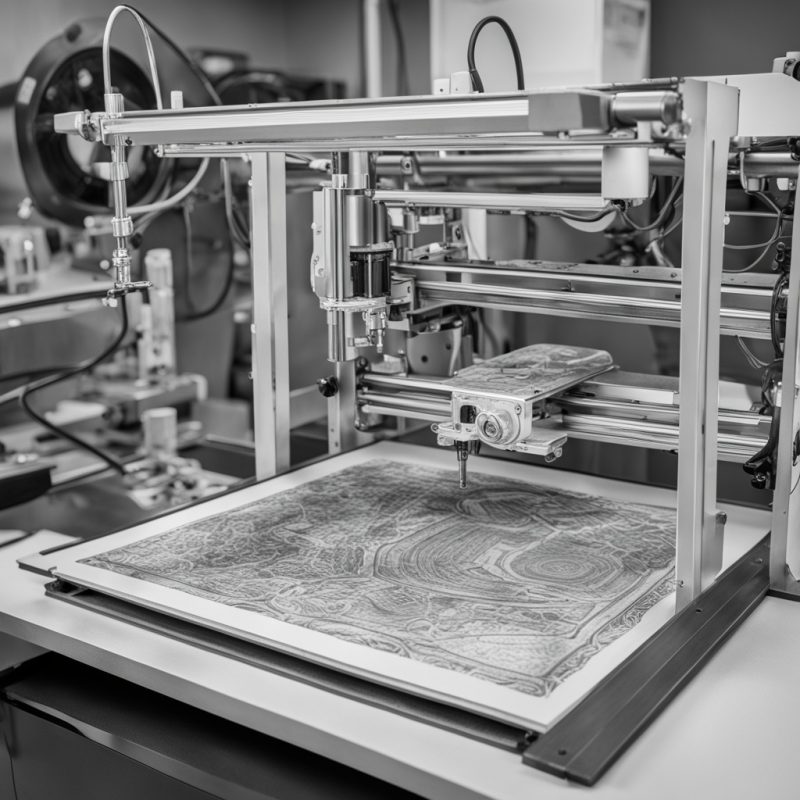

When choosing a laser branch cutter, it’s essential to consider its specifications and features to ensure it meets your needs. Here are some key aspects to look for:

- Laser Power: The power of the laser beam determines the depth and speed of engraving. Higher power lasers can handle thicker materials and faster engraving speeds.

- Engraving Area: The size of the workspace determines the maximum dimensions of the material you can engrave. Ensure the machine has an adequate engraving area for your projects.

- Software Compatibility: User-friendly software is crucial for designing and controlling the engraving process. Look for machines that come with intuitive software or are compatible with popular design tools.

- Material Handling: Features like automatic focus adjustment, air assist, and vacuum tables can enhance the engraving quality and ease of use.

The laser branch cutter excels in these areas, offering a balance of power, precision, and user-friendly features. Its compact design and DIY capabilities make it ideal for hobbyists and small businesses alike.

Material Compatibility

One of the standout features of laser engravers is their ability to work with a diverse range of materials. The laser branch cutter is compatible with a wide variety of materials, including:

- Wood: Engrave intricate patterns and text on wooden surfaces for a range of applications, from decorative items to furniture.

- Leather: Create personalized leather goods, such as wallets, belts, and journals.

- Acrylic: Produce vibrant, see-through engravings on acrylic sheets for signs and decorative pieces.

- Metal: While laser cutting is more common on metals, certain types can be engraved with the right settings and auxiliary gases.

- Paper and Cardboard: Ideal for making custom invitations, greeting cards, and other paper crafts.

Safety Considerations

Safety is paramount when working with laser engraving machines. Here are some essential safety tips:

- Eye Protection: Always wear laser-safe glasses when operating the machine to protect your eyes from laser radiation.

- Ventilation: Ensure proper ventilation to prevent the accumulation of laser-generated fumes and particles.

- Fire Precautions: Keep flammable materials away from the laser beam and have a fire extinguisher handy.

- Software Safety Checks: Use software features that prevent the laser from moving beyond predefined boundaries.

- Training: Provide comprehensive training to all operators to ensure they understand the machine’s safety features and proper procedures.

Industry Best Practices

Adopting industry best practices can enhance the efficiency and quality of your laser engraving projects. Here are some recommendations:

- Material Preparation: Ensure materials are clean, flat, and properly secured to avoid movement during engraving.

- Test Runs: Always perform test runs on scrap material to fine-tune settings before starting a final project.

- Regular Maintenance: Keep the machine clean and perform regular maintenance checks to prevent downtime and ensure optimal performance.

- Software Optimization: Utilize software features to optimize design layouts and reduce engraving time.

- Documentation: Maintain detailed records of settings and results for future reference and to replicate successful projects.

Cost-Benefit Analysis

Investing in a laser branch cutter can provide significant benefits, especially for businesses and hobbyists who frequently engage in laser engraving projects. Here’s a cost-benefit analysis to consider:

- Initial Investment: While the upfront cost can be substantial, the versatility and longevity of laser engravers often justify the expense.

- Operating Costs: Consumables such as lenses and gases are ongoing costs, but these are typically low compared to the machine’s output.

- Time Savings: Laser engravers offer significant time savings compared to traditional methods, allowing for higher productivity.

- Quality and Precision: The high quality and precision of laser-engraved designs can increase the value of products and services.

- Market Expansion: The ability to offer customized and personalized products can open up new market opportunities.

Maintenance Tips

Proper maintenance is crucial for keeping your laser branch cutter in top condition. Here are some maintenance tips:

- Clean the Lens: Regularly clean the laser lens to prevent dust and debris from affecting the beam quality.

- Check Belts and Pulleys: Inspect belts and pulleys for wear and tear, and replace them as needed to ensure smooth movement.

- Lubricate Moving Parts: Apply a suitable lubricant to moving parts to reduce friction and wear.

- Align the Beam: Periodically check and adjust the laser beam alignment to maintain precision.

- Software Updates: Keep the machine’s software up to date to benefit from the latest features and improvements.