Laser Cutter for Sheet Metal: Precision Engraving with Versatility

Sheet metal fabrication has evolved significantly over the years, and one of the most innovative tools to emerge is the . This machine combines precision, speed, and versatility, making it an essential tool for professionals in various industries. Whether you’re working on small-scale projects or large production runs, a laser cutter offers unparalleled flexibility. In this article, we’ll explore the features, benefits, and applications of this cutting-edge technology. Let’s dive in!

What is a Laser Cutter for Sheet Metal?

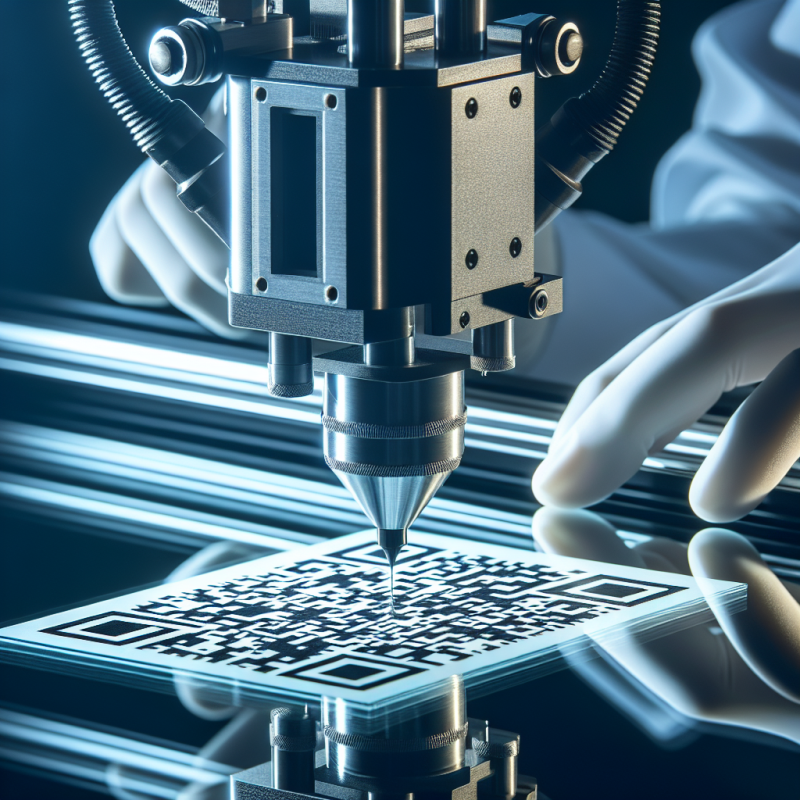

A is a machine that uses a focused laser beam to cut, engrave, or etch materials with extreme precision. Unlike traditional cutting methods that rely on mechanical tools, laser cutters use heat generated by the laser to melt, burn, or vaporize material along predetermined lines. This process results in clean, precise cuts without physical contact between the tool and the workpiece.

Laser cutters are highly versatile and can work with a wide range of materials, including steel, aluminum, stainless steel, and even non-metallic materials like wood, plastic, and glass. For sheet metal fabrication, these machines are particularly valuable due to their ability to handle thin gauge metals efficiently. Whether you’re creating intricate designs or simple geometric shapes, a laser cutter delivers consistent results every time.

Why Choose a Laser Cutter for Sheet Metal?

If you’re wondering why you should invest in a laser cutter for sheet metal, here are some compelling reasons:

- Precision and Accuracy: Laser cutters can achieve tolerances of +/- 0.001 inches, making them ideal for applications where precision is critical.

- Versatility: They can work with various materials and thicknesses, allowing you to handle a wide range of projects in one machine.

- Speed: Compared to traditional cutting methods, laser cutters are much faster, reducing production time significantly.

- Low Maintenance: With no physical contact between the tool and material, there’s less wear and tear on the machine.

- Cost-Effective: Laser cutting reduces waste and minimizes material costs, especially when working with expensive metals like stainless steel or brass.

These benefits make laser cutters a popular choice for industries ranging from automotive manufacturing to jewelry design. If you’re looking to upgrade your fabrication process, a laser cutter is definitely worth considering.

Applications of Laser Cutters in Sheet Metal Fabrication

Laser cutters are incredibly versatile and can be used in numerous applications within the sheet metal industry. Here are some common uses:

- Prototyping: Quickly create prototypes for new designs without spending time on expensive tooling.

- Cutting Complex Shapes: Laser cutters excel at creating intricate patterns and shapes that would be difficult or impossible to achieve with traditional methods.

- Engraving: Add detailed text, logos, or artwork to sheet metal surfaces with precision and clarity.

- Bulk Production: Laser cutters are efficient for high-volume production runs, ensuring consistent quality across all pieces.

- Metal Art: Create stunning metal art pieces by combining cutting and engraving techniques.

The ability to switch between cutting and engraving modes makes laser cutters a Swiss Army knife of sheet metal fabrication. Whether you’re working on custom projects or large-scale manufacturing, this machine can handle it all.

How to Choose the Right Laser Cutter for Sheet Metal

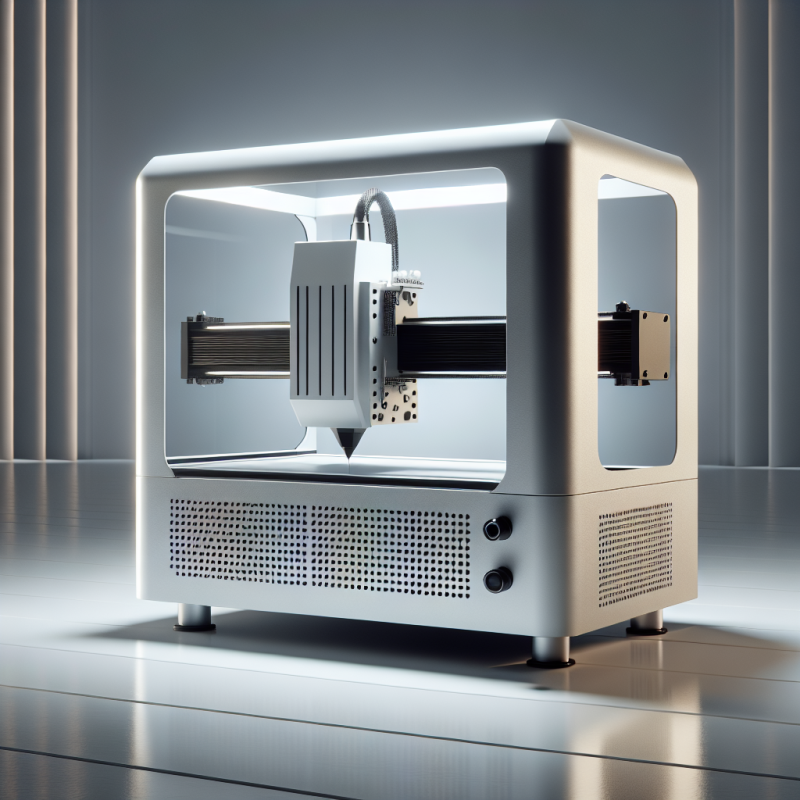

If you’re in the market for a laser cutter for sheet metal, there are several factors to consider. Here’s what you need to know:

1. Power Output

The power output of the laser determines its cutting capacity. Higher wattage lasers can cut through thicker materials at faster speeds. For sheet metal fabrication, a 500W to 2000W laser is typically sufficient for most applications. However, if you’re working with thick gauge metals or exotic materials, you may need a more powerful machine.

2. Material Compatibility

Not all lasers are created equal when it comes to material compatibility. For sheet metal fabrication, ensure the laser cutter is capable of handling common metals like steel, aluminum, and stainless steel. Some machines also support non-metallic materials, adding even more versatility to your workflow.

3. Software Integration

Modern laser cutters come with advanced software that allows you to design and program cuts directly on your computer. Look for a machine with intuitive software that supports popular CAD/CAM formats, making it easier to transition from design to production.

4. Build Quality and Durability

Investing in a high-quality laser cutter is essential for long-term performance. Check reviews and compare the build quality of different models to ensure you’re getting a machine that can withstand heavy use without breaking down frequently.

By carefully evaluating these factors, you can select a that meets your specific needs and budget requirements.

Tips for Maximizing Laser Cutter Performance

To get the most out of your laser cutter, follow these tips:

- Calibrate Regularly: Ensure the machine is properly calibrated to maintain cutting accuracy and prevent errors in your projects.

- Clean the Work Area: Keep the work area free of dust and debris to avoid laser reflections and ensure optimal performance.

- Use Proper Safety Gear: Laser cutters produce intense light and heat, so always wear protective eyewear and gloves when operating the machine.

- Experiment with Settings: Different materials require different settings. Don’t be afraid to experiment with power levels, cutting speeds, and focal points to achieve the best results.

- Maintain the Laser Tube: The laser tube is the heart of the machine. Follow the manufacturer’s recommendations for maintenance to prolong its lifespan.

By following these simple tips, you can maximize the performance and longevity of your laser cutter, ensuring it remains a valuable tool in your fabrication arsenal for years to come.

Frequently Asked Questions

1. Can a laser cutter be used for both cutting and engraving?

Yes! Most laser cutters are designed to handle both cutting and engraving, giving you the flexibility to work on various projects in one machine.

2. What materials can a laser cutter work with?

Laser cutters are compatible with a wide range of materials, including steel, aluminum, stainless steel, wood, plastic, glass, and more. Check the specifications of your machine for exact material compatibility.

3. How much does a laser cutter cost?

The cost of a laser cutter varies depending on its power output, features, and brand. Entry-level models can start at around $1000, while high-end industrial-grade machines can exceed $25,000.

4. Is it easy to learn how to use a laser cutter?

Laser cutters are relatively user-friendly, especially with modern software interfaces. However, some practice and experimentation may be needed to master advanced techniques.

5. How often do I need to maintain my laser cutter?

Maintenance frequency depends on usage levels but typically includes regular cleaning of the work area, checking the alignment of the laser tube, and replacing consumable parts like lenses and mirrors as needed.

Conclusion

The is a game-changer in the world of fabrication, offering unparalleled precision, versatility, and efficiency. Whether you’re a hobbyist, small business owner, or industrial manufacturer, investing in a high-quality laser cutter can revolutionize your workflow and take your projects to new heights. So why wait? Take the leap today and discover the endless possibilities that a laser cutter has to offer!