Laser Engraved QR Codes: Revolutionizing Precision and Durability with Advanced Laser Engraving Machines

Laser engraved QR codes are transforming industries by offering unmatched precision, durability, and versatility. As businesses increasingly rely on QR codes for tracking, marketing, and authentication, the demand for high-quality laser engraved qr codes has surged. This article explores how modern laser engraving machines enable the creation of these sophisticated codes, their applications, and why they are a game-changer for manufacturers and end-users alike.

Why Choose Laser Engraving for QR Codes?

Traditional methods like inkjet printing or sticker labels often fail to meet the durability requirements of industrial environments. Laser engraving, however, uses concentrated light beams to etch QR codes directly onto materials such as metal, plastic, wood, or glass. This process ensures:

- Permanence: Unlike printed codes, laser engraved qr codes resist fading, abrasion, and chemical exposure.

- High Resolution: Lasers achieve micron-level precision, critical for small yet scannable QR codes.

- Speed: Modern laser engraving machines can process hundreds of codes per hour.

Did you know? A single laser engraved qr code can store up to 7,089 numeric characters—ideal for complex data storage in industries like aerospace or healthcare.

Applications of Laser Engraved QR Codes

The versatility of laser engraved qr codes makes them indispensable across sectors:

- Manufacturing: Track parts through assembly lines with tamper-proof codes.

- Medical Devices: Ensure traceability and compliance with FDA regulations.

- Retail: Embed QR codes on luxury goods to combat counterfeiting.

- Automotive: Label components for warranty validation and recalls.

Question: What makes laser engraved qr codes more secure than traditional labels? The answer lies in their inability to be removed or altered without visible damage.

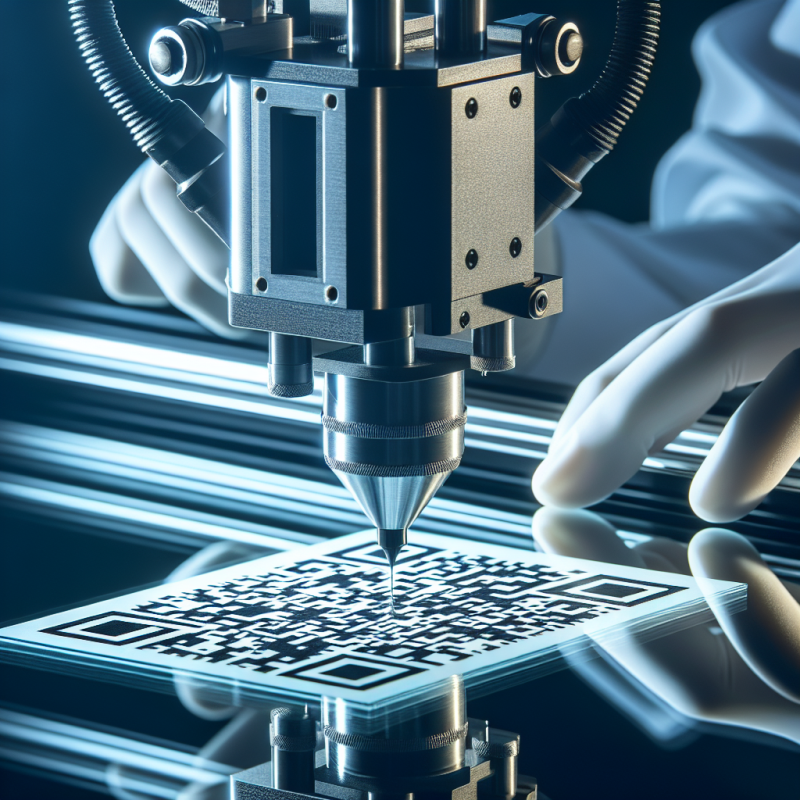

How Do Laser Engraving Machines Work?

Modern laser engraving machines use CO2, fiber, or UV lasers to vaporize material surfaces, creating permanent marks. Here’s a step-by-step breakdown:

- Design Input: QR code data is uploaded via software (e.g., AutoCAD or CorelDraw).

- Calibration: The machine adjusts focus and power based on material type.

- Engraving: The laser etches the code with pinpoint accuracy.

- Verification: Integrated cameras scan the code to ensure readability.

Pro Tip: For metals, fiber lasers are preferred due to their shorter wavelengths, while CO2 lasers excel on organic materials like wood.

Key Features of a High-Quality Laser Engraving Machine

Not all laser engraving machines are built equal. When selecting equipment for laser engraved qr codes, prioritize these features:

- Power Range: 20W–100W for flexibility across materials.

- Software Compatibility: Supports industry-standard design tools.

- Cooling System: Ensures consistent performance during long runs.

- Safety Certifications: Compliant with IEC 60825-1 or FDA standards.

Fun Fact: Some machines now integrate AI to auto-correct misaligned engravings!

Material Compatibility: What Can You Engrave?

Laser engraved qr codes work on virtually any surface. Common materials include:

- Metals: Stainless steel, aluminum, titanium.

- Plastics: ABS, polycarbonate, acrylic.

- Glass/Ceramics: Perfect for decorative or industrial uses.

- Wood: Ideal for artisanal products or packaging.

Question: Can lasers engrave curved surfaces? Yes! Advanced rotary attachments enable cylindrical engraving.

Overcoming Challenges in Laser QR Code Engraving

While laser engraved qr codes offer immense benefits, challenges like reflective surfaces or heat-sensitive materials require expertise. Solutions include:

- Pulsed Lasers: Reduce heat buildup on plastics.

- Anti-Reflective Coatings: Improve marking contrast on shiny metals.

- Dynamic Focus: Maintain clarity on uneven surfaces.

Case Study: A medical supplier achieved 99.9% scan rates on surgical tools using UV laser engraving.

Future Trends in Laser Engraving Technology

The future of laser engraving machines is bright, driven by innovations like:

- 3D Engraving: Create raised QR codes for tactile identification.

- Green Lasers: Enhance marking speed on copper and gold.

- IoT Integration: Machines that self-optimize based on real-time data.

Question: Will laser engraved qr codes replace barcodes? While QR codes store more data, both will coexist for niche applications.

FAQs About Laser Engraved QR Codes

Q: How long does it take to engrave a QR code?

A: Typically 3–10 seconds, depending on size and complexity.

Q: Are laser-engraved codes recyclable?

A: Yes! Unlike stickers, they don’t contaminate materials during recycling.

Q: Do I need programming skills to operate a laser engraver?

A: No—most machines use intuitive drag-and-drop software.

Conclusion

Laser engraved qr codes represent the pinnacle of reliable, scalable, and secure marking solutions. By investing in advanced laser engraving machines, businesses can future-proof their operations while meeting stringent industry standards. Whether you’re marking aerospace components or designer jewelry, the precision of laser technology ensures your QR codes will stand the test of time.

Final Question: Is your business ready to upgrade to laser engraved qr codes? The answer is almost certainly yes.