Laser Engraver for Glass: A Comprehensive Guide to Glass Laser Engraving Machines

Introduction

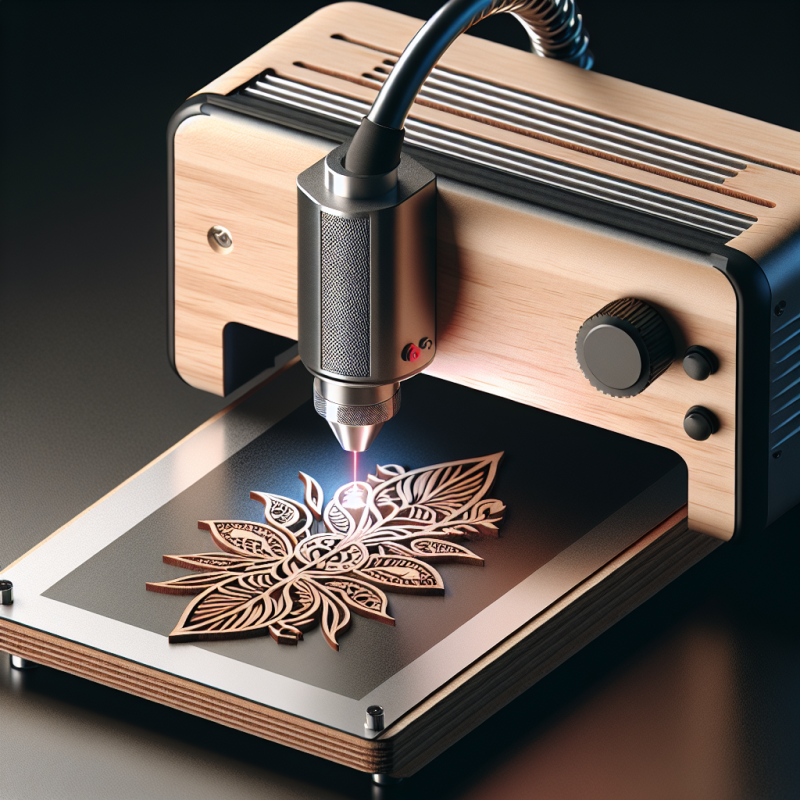

Laser engraving technology has revolutionized the way we create intricate designs and patterns on various materials, including glass. With the advent of specialized laser engraver for glass machines, artists, craftsmen, and industries can now achieve precision and detail that was previously unimaginable. This guide delves into the technology, applications, machine specifications, material compatibility, safety considerations, industry best practices, cost-benefit analysis, maintenance tips, and project ideas for glass laser engraving.

Laser Engraving Technology and Applications

Laser engraving technology uses a high-intensity laser beam to create designs on a surface by removing material through ablation or vaporization. This process is highly precise and can produce intricate details, making it ideal for a variety of applications.

In the context of glass laser engraving, the technology enables the creation of stunning patterns, images, and text on glass surfaces. This can be used for a multitude of purposes, such as:

- Personalized gifts and souvenirs

- Artistic creations and decorations

- Commercial signage and branding

- Functional elements like etched glassware and mirrors

- Architectural designs in glass installations

The versatility of laser engraver for glass machines allows for endless creativity and customization, making them a valuable tool for both professionals and hobbyists.

Machine Specifications and Features

When choosing a laser engraver for glass, several factors need to be considered to ensure it meets your specific needs. Key specifications and features to look for include:

- Laser Power: Higher power lasers can achieve deeper and faster engraving, but they also require more energy and may be more expensive. For glass, a laser with at least 40W of power is typically recommended.

- Beam Quality: A focused, stable laser beam ensures precise and consistent engraving. Look for machines with a wavelength suitable for glass, such as those in the infrared spectrum.

- Workspace Dimensions: Ensure the machine’s workspace is large enough to accommodate the size of the glass pieces you plan to engrave.

- Software Compatibility: Easy-to-use software with design capabilities and compatibility with popular file formats (like Adobe Illustrator or CorelDRAW) simplifies the workflow.

- Safety Features: Essential safety features include enclosed work areas, emergency stop buttons, and interlocks to prevent accidental exposure to the laser beam.

The laser engraver for glass from OmTech, such as the Hawk F1, offers these specifications and more, making it a popular choice for both professional and hobbyist use.

Material Compatibility

While laser engravers can work with a wide range of materials, not all machines are suitable for glass. Glass has unique properties that make it both challenging and rewarding to engrave. It requires a specific type of laser that can safely and effectively interact with its surface without causing shattering or excessive heat stress.

When choosing a laser engraver for glass, ensure it is specifically designed to handle this material. Machines equipped with the right wavelength and power settings can produce beautiful results on various types of glass, including clear, frosted, and colored glass.

Safety Considerations

Laser engraving machines, especially those designed for glass, operate with high-intensity beams that can pose serious risks if not handled properly. Safety is paramount when working with these machines.

Key safety considerations include:

- Eye Protection: Always wear laser-safe glasses when operating the machine or when in the vicinity of the laser beam.

- Ventilation: Ensure proper ventilation to prevent the accumulation of harmful fumes and particles generated during engraving.

- Emergency Stops: Machines should be equipped with easily accessible emergency stop buttons to immediately halt the laser in case of an emergency.

- Training: Operators should be thoroughly trained on the safe use of the machine, including understanding all safety features and protocols.

Adhering to these safety guidelines can help prevent accidents and ensure a safe working environment.

Industry Best Practices

To achieve optimal results and extend the lifespan of your laser engraver for glass, follow industry best practices:

- Regular Maintenance: Keep the machine clean and free of debris. Regularly check and replace worn-out parts, such as lenses and mirrors.

- Optimal Focus: Ensure the laser beam is properly focused for the material you are engraving. Improper focus can lead to poor quality results.

- Test Runs:

Always perform test runs on scrap material before starting a new project to adjust settings and ensure everything is functioning correctly.

- Material Preparation: Clean and prepare the glass surface to remove any contaminants that could interfere with the engraving process.

By adhering to these practices, you can ensure that your laser engraver for glass operates efficiently and produces high-quality results.

Cost-Benefit Analysis

Investing in a laser engraver for glass can be a significant expenditure, but it can also offer significant benefits. To determine if it’s the right investment for you, consider the following cost-benefit analysis:

- Initial Cost: Evaluate the upfront cost of the machine, including any accessories or software required.

- Operational Costs: Consider ongoing costs such as electricity, maintenance, and replacement parts.

- Revenue Generation: Assess the potential for increased revenue through new products and services offered with the ability to laser engrave glass.

- Time Savings: Automation and precision of laser engraving can reduce labor time and increase productivity.

- Versatility: A versatile machine that can handle multiple materials can offer a broader range of services and applications.

Weighing these factors can help you make an informed decision about the potential return on investment for a laser engraver for glass.

Maintenance Tips

Proper maintenance is crucial for keeping your laser engraver for glass in optimal condition and extending its lifespan. Here are some maintenance tips:

- Clean the Optics: Regularly clean the lenses and mirrors to remove dust and debris that can affect beam quality.

- Lubricate Moving Parts