Laser Engraving Anodized Aluminum: A Comprehensive Guide

Laser engraving has become a popular method for creating intricate designs on various materials, including anodized aluminum. This process offers precision, durability, and a professional finish that is hard to achieve with traditional methods. In this article, we will explore the ins and outs of laser engraving anodized aluminum, its applications, benefits, challenges, and tips for achieving the best results. Whether you’re a hobbyist or a professional, this guide will provide you with valuable insights into this versatile technique.

What is Laser Engraving?

Laser engraving is a process that uses a focused laser beam to etch or cut designs onto the surface of a material. The laser produces intense heat, which vaporizes or removes the material layer by layer. This method is highly precise and can create detailed patterns, text, or graphics on various surfaces, including metal, wood, plastic, and glass.

Anodized aluminum is a popular choice for laser engraving due to its durability, lightweight properties, and aesthetic appeal. The anodizing process creates a protective oxide layer on the surface of the aluminum, which enhances its resistance to corrosion and wear. This makes it ideal for products that require both functionality and visual appeal.

Advantages of Laser Engraving Anodized Aluminum

Laser engraving anodized aluminum offers several advantages over traditional methods:

- Precision and Detail: The laser beam can create intricate designs with exceptional accuracy, making it perfect for complex patterns or text.

- Durability: The engraved designs are permanent and resistant to wear, ensuring long-lasting results.

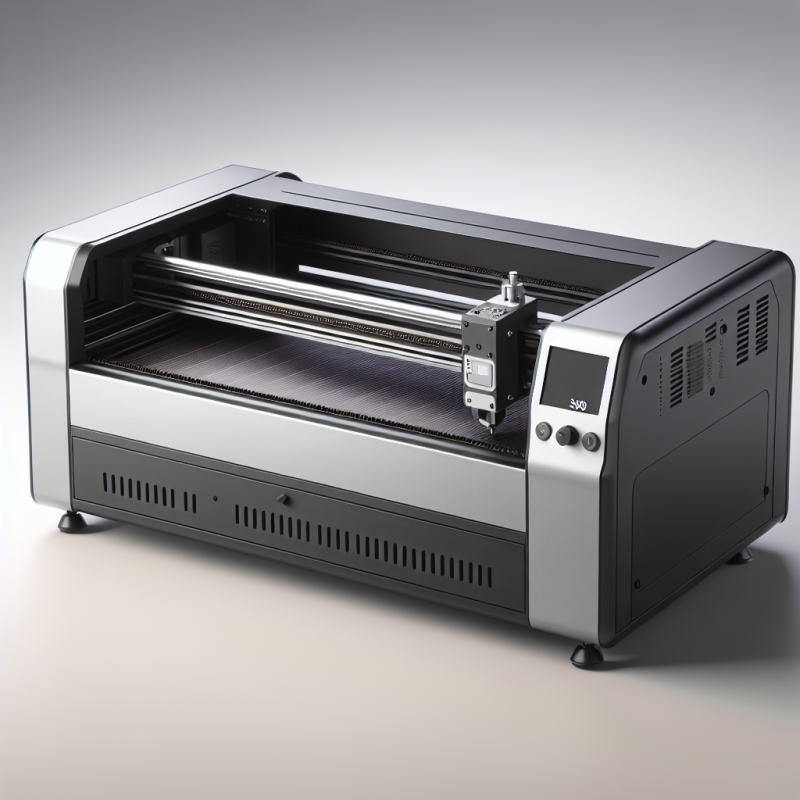

- Ease of Use: Laser engraving machines are user-friendly and can be operated with minimal training.

- Versatility: The process can be used for both small-scale projects and large production runs.

If you’re wondering, “How do I get started with laser engraving anodized aluminum?” the answer is simpler than you might think. With the right equipment, such as a portable laser engraver, you can begin creating your own designs in no time.

Applications of Laser Engraving Anodized Aluminum

Laser engraving anodized aluminum is widely used across various industries. Some common applications include:

- Jewelry and Watches: Creating personalized engravings on metal components, such as watch faces or bracelet links.

- Furniture: Adding decorative patterns or logos to aluminum furniture parts.

- Signage: Producing high-quality signs with detailed text and graphics.

- Medical Devices: Engraving serial numbers, instructions, or branding on medical equipment made from anodized aluminum.

The versatility of laser engraving makes it a go-to solution for businesses looking to enhance their products with professional-quality designs. For example, if you’re in the custom gift market, laser-engraved anodized aluminum items can be a hit among customers seeking unique and durable gifts.

Challenges of Laser Engraving Anodized Aluminum

While laser engraving offers numerous benefits, there are some challenges to consider:

- Material Thickness: Thicker anodized aluminum layers may require more powerful lasers or multiple passes to achieve the desired depth.

- Surface Preparation: The surface of anodized aluminum must be clean and free of contaminants for optimal engraving results.

- Color Variation: The anodizing process can create color variations, which may affect the visibility of engraved designs. Testing is often required to ensure consistency.

If you’re new to laser engraving, it’s essential to start with small projects and experiment with different settings to understand how the material responds to the laser beam. This trial-and-error approach will help you achieve the best results while minimizing waste.

Tips for Successful Laser Engraving

To ensure successful laser engraving on anodized aluminum, follow these tips:

- Use High-Quality Equipment: Invest in a reliable laser engraver, such as the , to achieve precise and consistent results.

- Test Your Material: Before starting your project, test the material with different laser settings to determine the optimal power and speed for engraving.

- Ensure Proper Ventilation: Laser engraving produces fumes and particulate matter. Always work in a well-ventilated area or use a fume extraction system.

- Maintain Your Equipment: Regularly clean and maintain your laser engraver to ensure it operates at peak performance and longevity.

By following these tips, you can create stunning designs on anodized aluminum with ease and confidence. Remember, practice makes perfect! Don’t hesitate to experiment with different designs and techniques to expand your skills.

Frequently Asked Questions About Laser Engraving Anodized Aluminum

If you’re still unsure about laser engraving anodized aluminum, here are answers to some common questions:

- Q: Can I engrave on any type of aluminum?

A: While most types of aluminum can be engraved, anodized aluminum is preferred due to its smooth surface and durability.

- Q: How deep can I engrave on anodized aluminum?

A: The depth depends on the laser’s power and the material’s thickness. Thicker layers allow for deeper engravings.

- Q: Is laser engraving safe for delicate designs?

A: Yes, laser engraving is highly precise and can handle intricate designs without damaging the surrounding material.

Conclusion

Laser engraving anodized aluminum is a versatile and efficient method for creating durable, high-quality designs on metal surfaces. Whether you’re working on small-scale projects or large production runs, this technique offers unmatched precision and versatility. With the right equipment, such as a portable laser engraver, and proper preparation, you can achieve stunning results that will impress your customers or clients.

If you’re ready to take your laser engraving skills to the next level, consider investing in a reliable machine like the . With practice and experimentation, you’ll be able to unlock the full potential of this exciting. Happy engraving!