Laser Engraving Machines: Unveiling the Precision and Versatility of Modern Laser Technology

Laser Engraving Technology and Applications

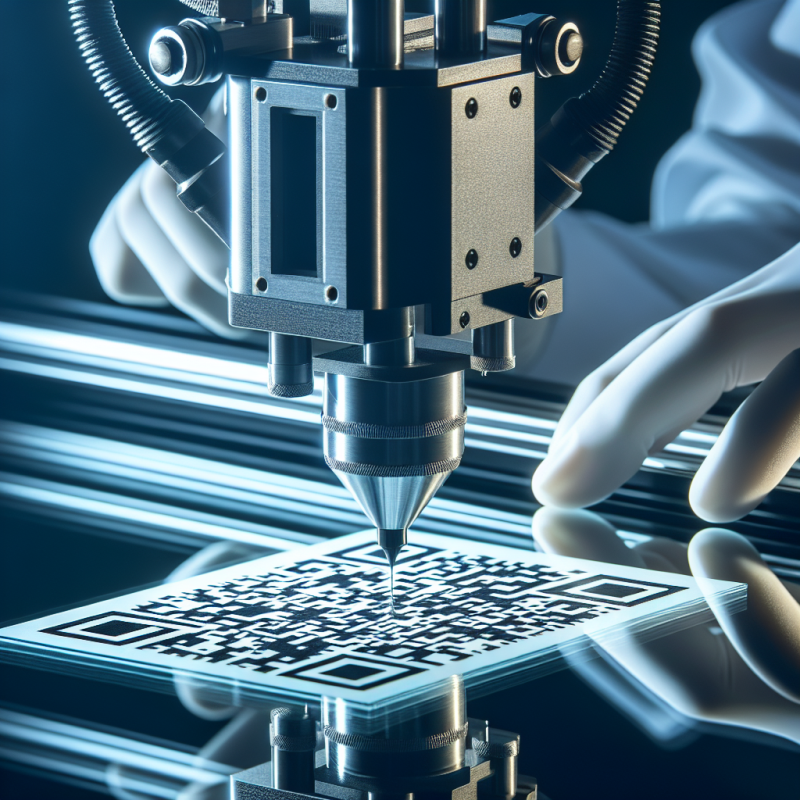

Laser engraving technology has revolutionized the world of customization and personalization, offering unparalleled precision and versatility across various industries. At its core, a engraving machine laser employs a high-intensity laser beam to create intricate designs, logos, text, or patterns on a wide range of materials. This non-contact process allows for detailed and consistent results, making it an ideal choice for a multitude of applications.

One of the most prominent applications of laser engraving is in the jewelry industry, where intricate designs and personal inscriptions can be etched onto metal surfaces with remarkable precision. The automotive industry also leverages laser engraving for part marking, serialization, and branding. Additionally, the art and craft sector has embraced laser engraving for woodworking, glass etching, and personalized gifts, transforming plain surfaces into works of art.

Beyond these traditional sectors, laser engraving machines have found their way into the medical field for labeling surgical instruments and implants, the aerospace industry for component tracing, and even in education and DIY projects, where they enable creative expression and learning through hands-on experience.

Machine Specifications and Features

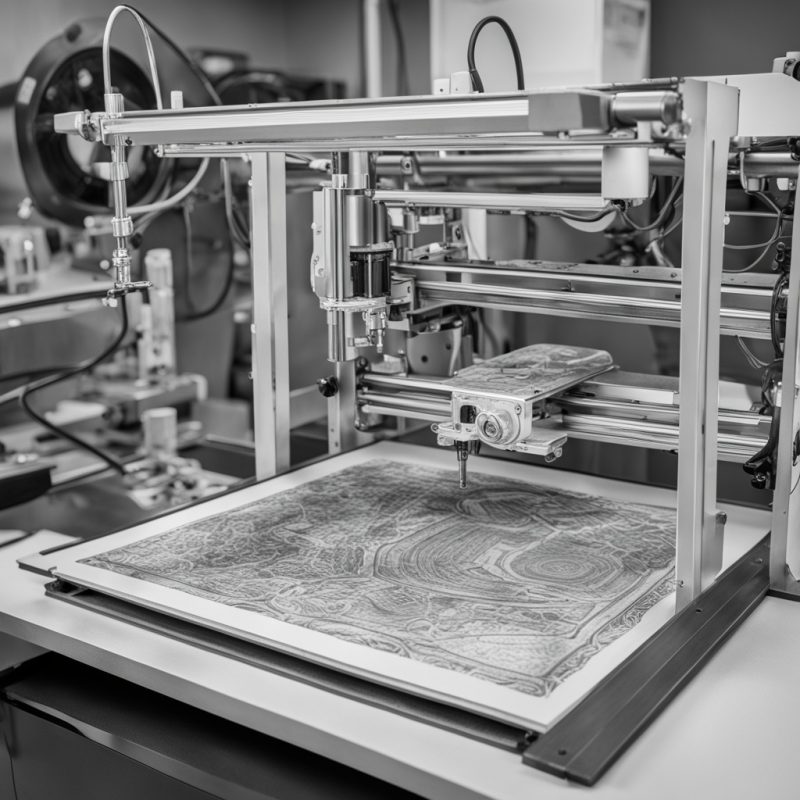

When selecting a engraving machine laser, understanding its specifications and features is crucial to ensure it meets your specific needs. Key specifications to consider include:

- Laser Power: Higher wattage lasers can cut thicker materials and engrave faster, but they also consume more energy and are more expensive. Common laser powers range from 10W to several hundred watts.

- Working Area: This determines the maximum size of the object that can be engraved. Machines with larger working areas are more versatile but also more costly and space-consuming.

- Resolution: Higher resolution results in finer details and clearer images. Look for machines offering resolutions of at least 1000 dots per inch (DPI).

- Software Compatibility: Ensure the machine is compatible with the design software you plan to use, such as Adobe Illustrator, CorelDRAW, or Inkscape.

Modern laser engraving machines come with various advanced features such as autofocus, which adjusts the laser focus automatically based on material thickness, and built-in cameras for real-time monitoring of the engraving process. Some models also offer wireless connectivity and mobile app control, enhancing usability and convenience.

Material Compatibility

One of the most appealing aspects of laser engraving is its versatility in terms of material compatibility. Lasers can interact with a diverse range of materials, each requiring specific settings to achieve optimal results:

- Metals: Including stainless steel, aluminum, and brass. These materials typically require a coating or marking spray to enhance contrast.

- Woods: From softwoods like pine to hardwoods like oak. Lasers can create beautiful, intricate designs on wooden surfaces.

- Plastics: Such as acrylic, PVC, and polyethylene. Lasers can cut through plastics and create detailed engravings.

- Glass and Ceramics: Lasers can etch these materials, often creating a frosted or colored effect.

- Leather and Fabrics: Suitable for branding and personalization, lasers can create clean, precise marks on leather goods and textiles.

Safety Considerations

Operating a engraving machine laser involves handling high-energy beams and potentially hazardous materials, necessitating stringent safety measures:

- Eye Protection: Always wear laser-safe glasses when operating or observing the laser in action.

- Ventilation: Ensure adequate ventilation to prevent the accumulation of smoke and fumes, which can be harmful when inhaled.

- Fire Precautions: Keep flammable materials away from the laser workspace and have a fire extinguisher handy.

- Software Safety Features: Utilize software features that allow you to pause or stop the laser immediately in case of an emergency.

Additionally, it’s crucial to familiarize yourself with the machine’s manual and safety instructions before operating it. Regular maintenance and inspections are also vital to prevent accidents and ensure long-term machine performance.

Industry Best Practices

To get the most out of your engraving machine laser and ensure professional-quality results, follow these industry best practices:

- Material Preparation: Clean and prepare the material surface to remove any dirt, grease, or coatings that could affect the laser’s interaction.

- Test Runs: Perform test runs on scrap material to fine-tune settings such as power, speed, and frequency.

- Use Fixtures and Jigs: These can help stabilize the material and ensure consistent positioning, leading to more accurate and repeatable results.

- Regular Calibration: Keep the machine calibrated to maintain precision and avoid errors.

- Software Optimization: Utilize design software features to optimize paths and reduce unnecessary laser movements, saving time and improving efficiency.

Cost-Benefit Analysis

Investing in a engraving machine laser can be a significant expenditure, but it often pays for itself through increased productivity, reduced labor costs, and the ability to offer customized products. Here’s a breakdown of potential costs and benefits:

- Initial Investment: Includes the cost of the machine, accessories, and installation.

- Operational Costs: Include electricity, consumables (e.g., marking spray), and maintenance.

- Labor Savings: Automation reduces the need for manual labor, speeding up production times.

- Customization Potential: Enables businesses to offer personalized products, increasing customer satisfaction and market appeal.

Maintenance Tips

Proper maintenance is crucial for keeping your engraving machine laser in top condition and extending its lifespan. Here are some maintenance tips:

- Regular Cleaning: Clean the lens and mirrors regularly to prevent dust and debris from reducing beam quality.

- Lubrication: Ensure moving parts are regularly lubricated to reduce friction and wear.

- Cooling System: Check the cooling system for any leaks or blockages, as overheating can damage the laser tube.

- Firmware Updates: Keep the machine’s firmware up to date to benefit from the latest features and improvements.

- Professional Services: Consider scheduling regular maintenance checks with a qualified technician.

Project Ideas and Tutorials

To inspire your creativity and help you get started with your engraving machine laser, here are some project ideas and tutorials: