Photo Laser Engraving on Wood: A Comprehensive Guide

Laser Engraving Technology and Applications

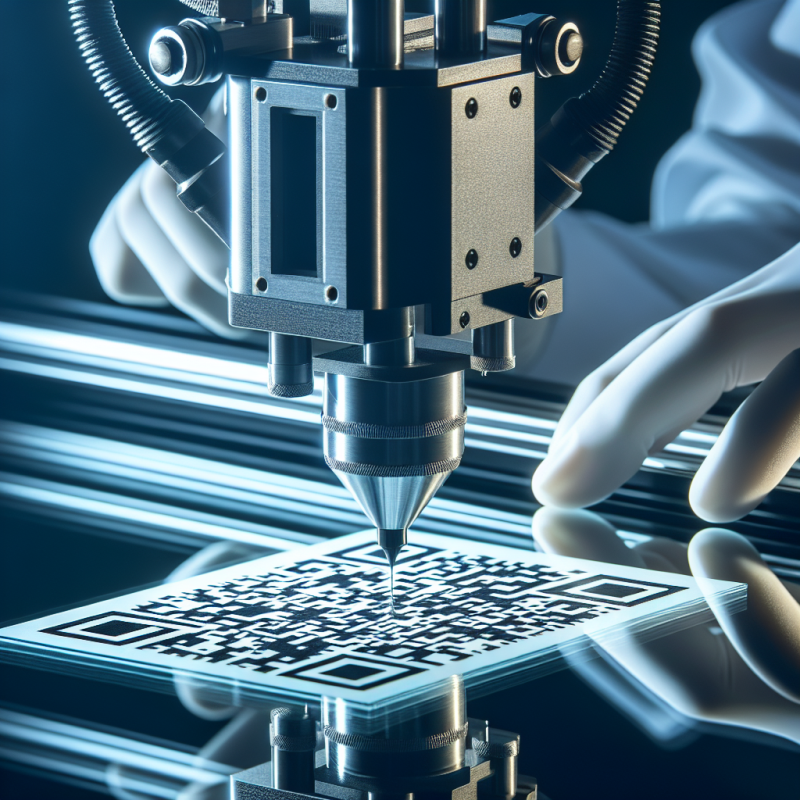

Laser engraving technology has revolutionized the world of art and craftsmanship, especially when it comes to photo laser engraving on wood. This innovative process uses a high-intensity laser beam to create intricate designs, patterns, and even photographs on wooden surfaces. The precision and detail achieved through laser engraving are unparalleled, making it a popular choice for a wide range of applications.

From personalized gifts and home decor to commercial signage and art installations, photo laser engraving on wood offers endless possibilities. Artists and craftspeople can bring their creative visions to life, while businesses can utilize this technology to brand their products or create unique marketing materials. The versatility of laser engraving extends to functional items as well, such as cutting boards, coasters, and even musical instruments, adding a touch of elegance and personalization.

Machine Specifications and Features

When choosing a laser engraving machine for wood, it’s crucial to consider the specifications and features that will best suit your needs. High-quality machines like the one found at https://laserforengravingmachine.com/product/xtool-laser-engraver-laser-engraver-machine/ offer a combination of power, precision, and ease of use.

- Laser Power: The power of the laser beam determines the depth and speed of engraving. For detailed photo laser engraving on wood, a machine with a moderate to high laser power is ideal.

- Engraving Area: The size of the workspace is another important consideration. Machines with larger engraving areas allow for more ambitious projects, while smaller models are more suitable for detailed work on smaller pieces.

- Software Compatibility: Look for a machine that comes with user-friendly software that supports a wide range of file formats, including high-resolution images for photo laser engraving.

- Safety Features: Safety should always be a top priority. Look for machines with built-in safety features such as emergency stop buttons, enclosures, and exhaust systems to vent harmful fumes.

The XTool Laser Engraver stands out with its advanced features, including a high-precision laser module, a large engraving area, and intuitive software that makes it easy to import and edit designs.

Material Compatibility

Wood is a highly versatile material for laser engraving, offering a warm, natural look that enhances the beauty of any design. Different types of wood have unique properties that affect the engraving process. For instance, softer woods like pine and balsa are easier to engrave but may not provide the same level of detail as harder woods like oak or maple.

When working with photo laser engraving on wood, it’s important to choose a wood type that complements your design and can withstand the laser’s heat without burning or charring. Experimenting with different woods can yield varied results, adding to the creative possibilities.

Safety Considerations

Laser engraving machines operate using high-intensity laser beams, which can pose serious safety risks if not handled properly. Here are some essential safety tips to keep in mind:

- Wear Protective Gear: Always wear laser safety glasses and protective clothing to shield your eyes and skin from laser exposure.

- Ventilation: Ensure proper ventilation to prevent the buildup of harmful fumes and particles generated during the engraving process.

- Emergency Stop: Familiarize yourself with the emergency stop button and keep it within reach in case of an accident.

- Fire Precautions: Have a fire extinguisher nearby and be prepared to respond quickly in case of a fire.

In addition to these basic safety measures, it’s important to follow the manufacturer’s instructions and safety guidelines provided with your laser engraving machine.

Industry Best Practices

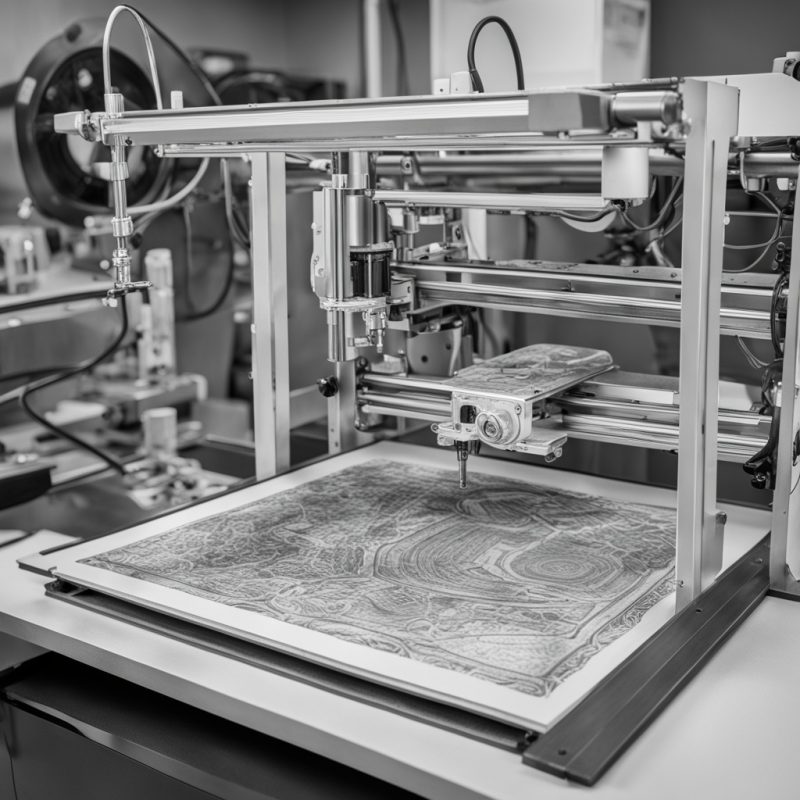

To get the most out of your photo laser engraving on wood machine and ensure high-quality results, follow these industry best practices:

- Calibrate Your Machine: Regularly calibrate your laser engraving machine to ensure accuracy and precision.

- Test Engravings: Always perform test engravings on scrap wood before starting a project to fine-tune settings and preview results.

- Use High-Resolution Images: For photo laser engraving, use high-resolution images to achieve the best possible detail and clarity.

- Clean and Maintain: Keep your machine clean and free of debris to prevent damage and ensure optimal performance.

By adhering to these best practices, you’ll be able to create stunning laser-engraved designs on wood that stand out for their quality and craftsmanship.

Cost-Benefit Analysis

Investing in a laser engraving machine for wood can be a significant financial commitment. However, the benefits far outweigh the costs, especially for those who plan to use the machine frequently or for commercial purposes.

In terms of cost savings, laser engraving machines allow for on-demand production, reducing the need for outsourcing and minimizing waste. They also offer a high degree of customization, enabling businesses to offer unique products and services that set them apart from the competition.

From a creative standpoint, the ability to bring intricate designs and high-resolution photos to life on wood opens up endless possibilities for artists and craftspeople. The potential for increased revenue and personal satisfaction makes the investment in a laser engraving machine well worth it.

Maintenance Tips

Proper maintenance is key to keeping your laser engraving machine in top condition and ensuring long-lasting performance. Here are some essential maintenance tips:

- Clean the Lens: Regularly clean the laser lens with a lens cloth and lens cleaner to remove dust and debris that can affect beam quality.

- Check Belts and Pulleys: Inspect belts and pulleys for wear and tear, and replace them as needed to maintain precision.

- Lubricate Moving Parts: Apply a suitable lubricant to moving parts to reduce friction and prevent wear.

- Regular Inspections:

Conduct regular inspections of the machine, looking for any signs of damage or wear that could affect performance.

By following these maintenance tips, you’ll be able to keep your laser engraving machine running smoothly and efficiently for years to come.

Project Ideas and Tutorials

Now that you’ve invested in a high-quality laser engraving machine for wood, it’s time to start creating! Here are some inspiring project ideas and tutorials to get you started:

- Personalized Cutting Boards: Engrave family names, dates, or monograms onto cutting boards for a personalized touch.

- Photo Coasters: Use high-resolution photos to create custom coasters that make perfect gifts for friends and family.

- Engraved Wood Art: Experiment with different wood types and designs to create unique pieces of art that showcase your creativity.

- Custom Signage: Create custom signs for businesses, events, or personal use, adding a touch of elegance and professionalism.

For those who are new to laser engraving, there are numerous online tutorials and resources available to guide you through the process. Many laser engraving machine manufacturers, including XTool, offer comprehensive user manuals and support to help you get started.

Don’t be