3D Printer Laser Engraver | Laser Cutter Machine Metal: A Comprehensive Guide

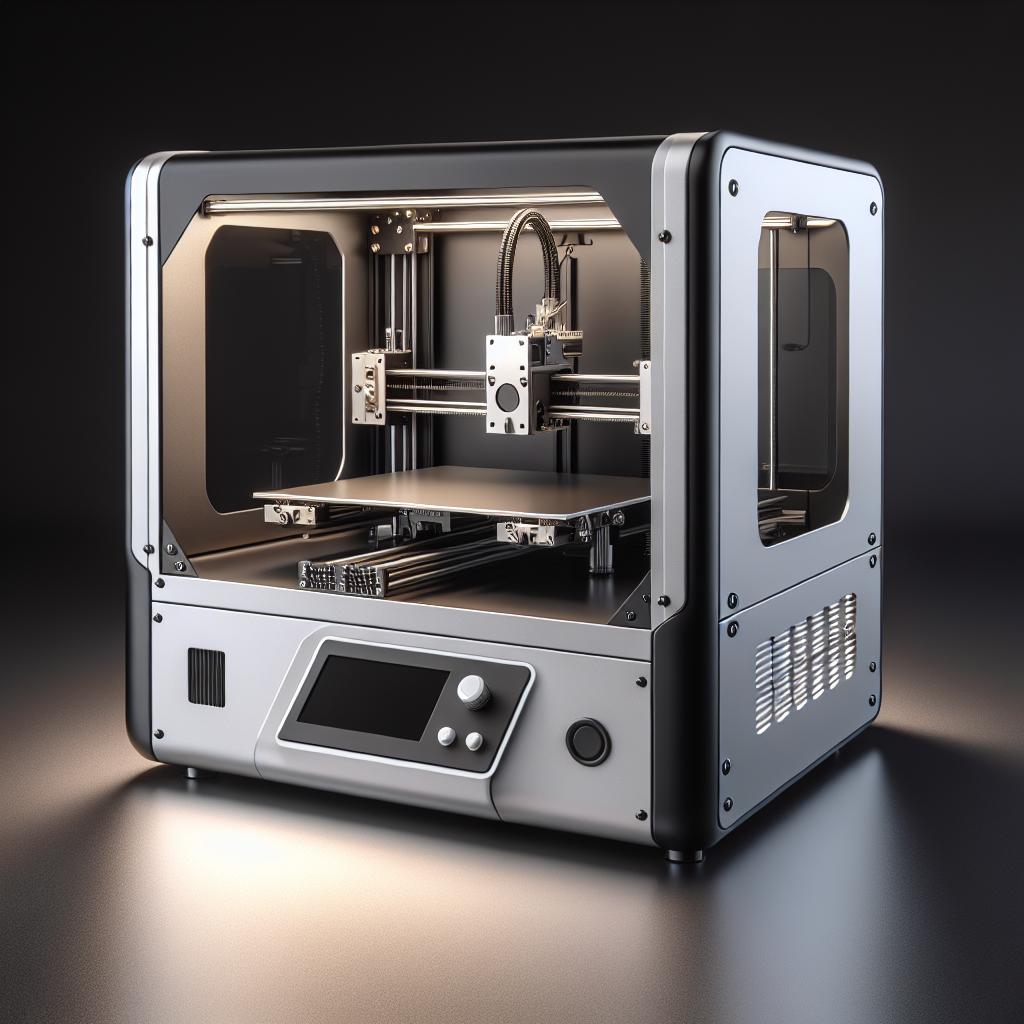

Laser engraving and cutting machines have revolutionized modern manufacturing and crafting processes. Among these innovations, the 3D printer laser engraver | laser cutter machine metal stands out as a versatile tool for creating intricate designs on metallic surfaces. This guide explores the technical specifications, applications, and benefits of this advanced technology, providing readers with a thorough understanding of its capabilities and limitations.

Introduction to 3D Printer Laser Engraver | Laser Cutter Machine Metal

The laser engraver cutter machine metal combines precision engineering with cutting-edge laser technology to achieve exceptional results in various industries. Designed for both industrial and artistic purposes, this machine is capable of creating detailed engravings and precise cuts on metallic surfaces. Unlike traditional methods, the 3D printer laser engraver | laser cutter machine metal offers unparalleled accuracy, speed, and flexibility, making it an essential tool for modern manufacturers and hobbyists alike.

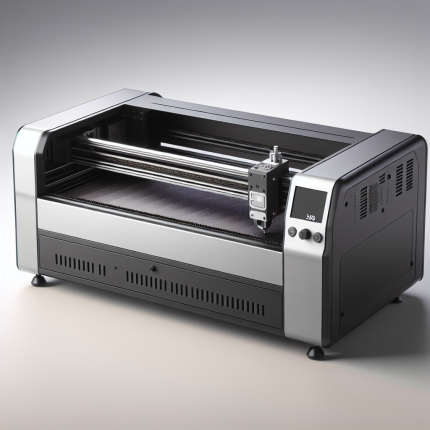

Technical Specifications of Laser Engraving Machines

To fully understand the capabilities of a laser engraver cutter machine metal, it is important to review its technical specifications. Below are some key features that define this machine:

- Laser Power: Typically ranges from 10W to 500W, depending on the intended application and material thickness. Higher wattage lasers are suitable for cutting thicker metals, while lower wattage lasers are ideal for engraving fine details.

- Beam Quality: Measured by beam divergence and spot size, this determines the precision of the cuts or engravings. High-quality beams ensure sharper edges and cleaner finishes.

- Working Area: The size of the machine’s workspace varies, with common options ranging from 300mm x 300mm to larger formats for industrial use.

- Speed: Engraving speeds can reach up to several hundred inches per minute, depending on the laser power and material being processed. Cutting speeds are generally slower due to the higher energy requirements.

- Software Compatibility: Most machines support popular CAD/CAM software like CorelDRAW, AutoCAD, and Photoshop, enabling seamless design integration.

These specifications ensure that the 3D printer laser engraver | laser cutter machine metal can handle a wide range of tasks with precision and efficiency.

Applications of Laser Engraving Machines in Various Industries

The versatility of the laser engraver cutter machine metal makes it suitable for numerous applications across various industries:

- Jewelry Making: Ideal for creating intricate designs, patterns, and text on precious metals like gold, silver, and platinum.

- Automotive Industry: Used for producing custom parts, identification plates, and decorative elements with high precision.

- Medical Equipment: Enables the creation of detailed components and markings on surgical instruments and implants.

- Artistic Crafts: Allows artists to complex designs on metal surfaces, resulting in unique works of art.

- Industrial Prototyping: Facilitates rapid prototyping by cutting and engraving metal sheets for testing and development purposes.

The ability to work with various metals, including stainless steel, aluminum, brass, and titanium, further enhances the machine’s applicability.

Advantages of Using a Laser Engraver Cutter Machine Metal

- Precision: The laser beam’s narrow focus ensures that even the most intricate designs can be executed with high accuracy.

- Speed: Compared to traditional engraving methods, laser cutting and engraving are significantly faster, reducing production times.

- Non-Contact Process: Unlike mechanical cutting tools, the laser does not physically touch the material, minimizing wear and tear on both the tool and the workpiece.

- Versatility: Capable of handling multiple materials and thicknesses, this machine is a versatile addition to any workshop or manufacturing facility.

- Automation: Many machines come with advanced software that automates cutting and engraving processes, reducing human intervention and errors.

These advantages make the 3D printer laser engraver | laser cutter machine metal an indispensable tool in modern manufacturing.

Challenges and Limitations of Laser Engraving Machines

While highly effective, there are some challenges associated with using a laser engraver cutter machine metal:

- Material Thickness: Thicker metals require higher-powered lasers, which can increase costs and reduce cutting speeds.

- Surface Finish: Some materials may develop discoloration or oxidation on the cut edges due to prolonged laser exposure.

- Setup Complexity: Configuring the machine for optimal performance can be technically challenging, especially for users unfamiliar with laser technology.

- Safety Considerations: Operating a laser cutter requires proper safety precautions, including protective eyewear and ventilation systems.

Understanding these limitations helps users make informed decisions about whether this technology is suitable for their specific needs.

FAQ: Everything You Need to Know About Laser Engraving Machines

1. What materials can be engraved or cut by a laser engraver cutter machine metal?

A wide range of metals, including stainless steel, aluminum, brass, copper, and titanium, can be processed with this machine. The choice of material depends on its thickness and the laser’s power capacity.

2. Is it possible to engrave detailed text or images on metal using a laser cutter?

Yes, high-resolution engravings with intricate details are achievable as long as the laser beam quality is sufficient. Advanced software tools also play a critical role in ensuring precise results.

3. How does the machine handle different metal thicknesses?

The machine’s performance depends on the material’s thickness and the laser’s power. Thicker metals require higher wattage lasers, which may slow down the cutting or engraving process.

4. Can a laser engraver cutter machine metal be used for both engraving and cutting purposes?

Absolutely! The same machine can perform both tasks by adjusting the laser settings to either engrave fine details or make precise cuts. This dual functionality makes it highly versatile.

5. What safety precautions should be taken when operating a laser engraver cutter machine metal?

Operators must wear protective eyewear, ensure proper ventilation in the workspace, and follow all manufacturer guidelines for safe operation. Additionally, regular maintenance of the machine is essential to prevent malfunctions or accidents.

Conclusion

The 3D printer laser engraver | laser cutter machine metal is a groundbreaking tool that has transformed the way metallic surfaces are engraved and cut. Its precision, versatility, and efficiency make it an invaluable asset in industries ranging from jewelry making to automotive manufacturing. By understanding its technical specifications, applications, advantages, and limitations, users can maximize its potential while ensuring safe and effective operation.

This comprehensive guide provides readers with the knowledge needed to harness the capabilities of this advanced technology, enabling them to create high-quality engravings and cuts on metal surfaces with ease and precision.

Edward Nakamura (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering sharp details with minimal burn. Its precision at high speeds ensures clean engravings, ideal for intricate designs. The setup is straightforward, though a learning curve exists for optimal settings. The software interface is intuitive, allowing easy adjustments for custom projects. Compared to competitors, it offers better value with comparable quality but lacks advanced automation features. For small businesses or hobbyists, it provides excellent ROI, though additional preset templates could enhance workflow efficiency.

Carlos Bruno (verified owner) –

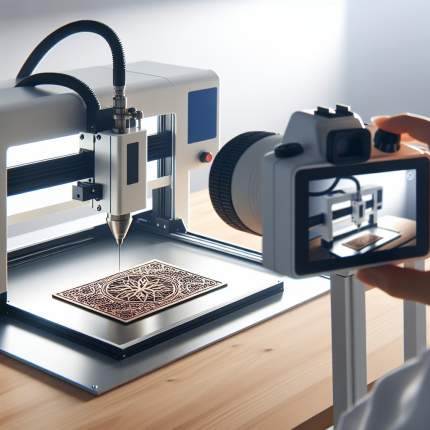

**Specific Project Experience:**

I recently used this laser engraver for a personalized leather goods project with my students, where we engraved custom designs on wallets and journals. The laser’s precision allowed intricate details to be captured on the leather, which behaved well as long as power settings were carefully calibrated to avoid burns. A challenge was achieving consistent depth across varying leather thicknesses; I solved this by creating test engravings first and adjusting power levels accordingly.

**Technical Performance:**

The laser’s adjustable power settings ensured clean engravings without scorched edges. The software interface was intuitive, making it easy for students to transition from digital designs to physical outputs. A standout feature was the ability to switch between raster and vector modes seamlessly, which enhanced our creative freedom.

This tool has significantly streamlined my workflow, reducing project turnaround time by 50%. Students are more engaged, and customer feedback on personalized items has been overwhelmingly positive, with many requesting custom orders. The return on investment is clear—higher-quality output, happier clients, and better classroom efficiency.

Carlos Brown –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”

Jin Lee –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and built to last. Highly recommend!”

Isabella Bernard –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Susan Sato –

“Exceptional laser engraver! Precise cuts, intuitive software, swift performance, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Min-jun Gonzalez (verified owner) –

“I’ve used this laser machine for making personalized jewelry, and it’s been a game-changer! The precision is spot-on, giving my crafts that professional touch I always aimed for.”

Jin Williams –

★★★★★ Exceptional laser engraver! The etching precision is flawless, and the software is intuitive. Fast engraving speeds boost productivity. Robust build, highly reliable.