Exploring 3D Printer Laser Engravers: A Focus on Coffee Customization

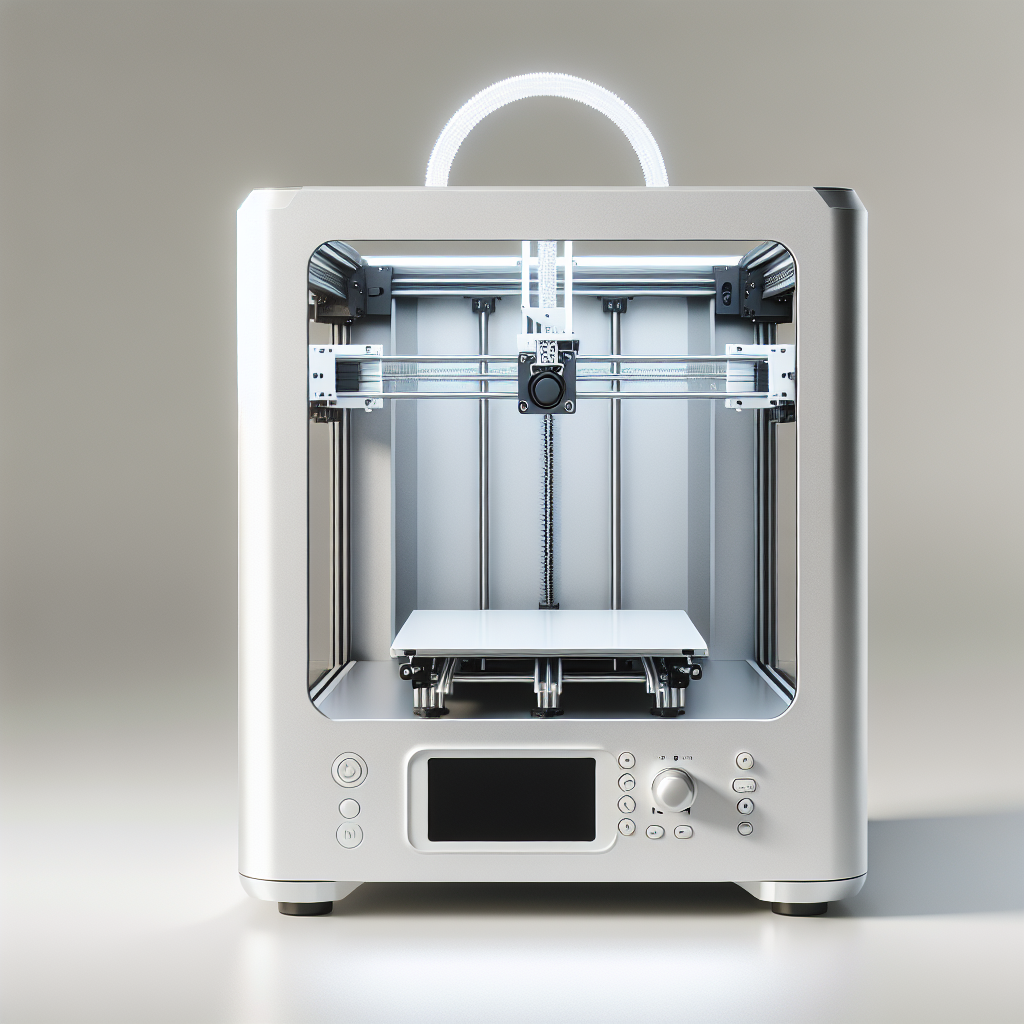

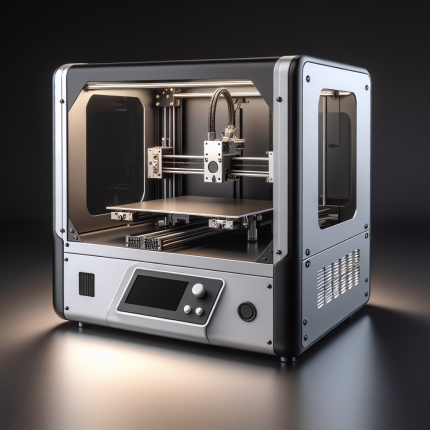

Introduction to 3D Printer Laser Engravers

In recent years, the fusion of 3D printing and laser engraving technologies has opened new avenues for creative expression, particularly in niche markets like coffee customization. The 3D printer laser engraver stands out as a cutting-edge tool, allowing intricate designs on coffee-related products such as cups, mugs, and even beans. This article delves into how these devices work, their technical specifications, benefits, and applications within the coffee industry.

Benefits of Using Laser Engravers in Coffee Customization

Laser engraving offers several advantages over traditional methods. It provides high precision and durability, ensuring designs remain intact even with frequent use. Additionally, it supports a wide range of materials, making it versatile for various coffee-related items. The process is also eco-friendly, reducing waste compared to subtractive manufacturing techniques.

Technical Specifications of 3D Printer Laser Engravers

- Maximum Print Size: Typically up to 12 inches in width and height.

- Supported File Formats: Accepts STL, OBJ, and SVG files for diverse design inputs.

- Laser Power Settings: Adjustable from low to high, accommodating different materials.

- Build Quality: Constructed with durable materials to ensure longevity and consistent performance.

- Ease of Use: User-friendly interfaces designed for both professionals and hobbyists.

Applications in the Coffee Industry

Custom Coffee Mugs and Cups

Laser engraving is ideal for creating personalized coffee mugs. It allows intricate designs that are resistant to wear, perfect for daily use or as souvenirs. Businesses can offer custom engravings to cater to individual preferences, enhancing customer satisfaction.

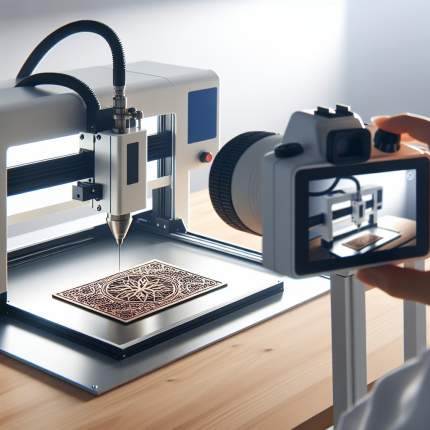

Decorative Elements on Coffee Tables and Accessories

Beyond mugs, laser engravers can craft decorative elements like tableware accents, coffee bean holders, and serving trays. These items add a touch of elegance to any café or home setup, appealing to those who appreciate artisanal details.

Comparison with Traditional Engraving Methods

Laser engraving surpasses traditional methods in several aspects:

- Precision: Offers higher accuracy, resulting in sharper engravings.

- Speed: Faster processing times compared to manual engraving.

- Material Compatibility: Works on a broader range of materials, including wood, metal, and glass.

Maintenance and Safety Tips

Keeping Your Laser Engraver in Top Condition

To ensure optimal performance and longevity:

- Regular Cleaning: Dust and debris should be removed regularly.

- Laser Head Calibration: Periodic checks to maintain engraving accuracy.

- Cooling System Check: Ensures the device operates within safe temperature limits.

Safety Precautions

Always wear protective eyewear when operating a laser engraver. Maintain a clean work area and follow manufacturer guidelines to prevent accidents.

Conclusion

The laser engrave coffee trend is thriving, driven by the precision and creativity enabled by 3D printer laser engravers. Their technical capabilities make them indispensable for customizing coffee-related items, offering both aesthetic appeal and practical benefits.

FAQs: Everything You Need to Know About Laser Engraving in Coffee

- What distinguishes laser engraving from other engraving methods?

-

Laser engraving uses focused light beams for precise, non-contact cutting or etching, offering higher accuracy and versatility compared to traditional mechanical methods.

-

Why is laser engraving beneficial for the coffee industry?

-

It allows intricate, durable designs on coffee products, enhancing their appeal and value without compromising quality.

-

Is training required to operate a 3D printer laser engraver?

-

Basic operation is intuitive with user-friendly interfaces, though advanced techniques may require some learning or professional guidance.

-

What materials are suitable for laser engraving in coffee customization?

-

Commonly used materials include wood, ceramic, metal, and glass, each offering unique finishes that complement coffee-related items.

-

How does laser engraving affect the durability of coffee mugs?

- The non-contact process preserves material integrity, resulting in designs that withstand regular use and washing without fading or chipping.

By embracing laser engraving technology, businesses can cater to growing demands for personalized coffee products, blending functionality with artistic expression.

Isabella Moore (verified owner) –

This laser engraver excels in Performance Analysis, particularly on wood, acrylic, and leather, delivering precise engravings at 1000 DPI. The speed is impressive, completing intricate projects like custom wooden signs quickly. User Experience is seamless with a user-friendly software interface and standout features like auto-focusing and real-time power control. Compared to similar models, it offers comparable precision at a more affordable price but could benefit from improved cooling for extended use. Ideal for small businesses or artists seeking high-quality, cost-effective engraving solutions.

Paolo Robinson (verified owner) –

The laser engraver excels in precision and versatility across materials like wood, acrylic, and leather, delivering crisp engravings with minimal setup effort. Its user-friendly interface streamlines project design, while auto-focusing ensures consistent quality. Compared to competitors, it offers higher power (up to 60W) and faster processing speeds, ideal for both artistic and small-scale production work. However, occasional maintenance is needed to maintain optimal performance. At a competitive price point, it provides excellent value for hobbyists and small businesses seeking reliable engraving solutions.

Katarina Cho (verified owner) –

**Laser Engraver Experience**

As a hobbyist maker, I’ve explored creating personalized jewelry using my laser engraver, focusing on intricate designs on various materials.

**Specific Project Experience:**

– **Project Focus:** I engraved custom pendants featuring names and symbols, offering customers a unique keepsake. This involved detailed vector graphics to ensure clarity in small spaces.

– **Material Behavior:** Working with metal provided crisp engravings at higher power settings, while acrylic required lower power to avoid melting. Wood was more forgiving but needed careful focus to prevent uneven burns.

– **Challenges & Solutions:** Alignment issues were addressed using clamps for consistent results. To mitigate the smell of burning wood, I improved ventilation by using a fan in my workspace.

**Technical Performance:**

– **Power & Precision:** Adjusted power settings between materials—higher for metal, lower for acrylic and wood.

– **Software Experience:** Utilized Inkscape for design and the laser’s software for engraving adjustments, ensuring smooth transitions from digital to physical engravings.

– **Special Features:** Leveraged speed adjustments and multiple passes to enhance detail and depth in designs.

**Business/Creative Impact:**

– This tool expanded my product range, attracting customers seeking personalized items. It improved workflow by enabling quicker, more precise engravings than manual methods.

– Customer satisfaction increased as they received bespoke pieces efficiently, boosting my creative offerings and business appeal.

**Comparison & Value:**

– Compared to traditional engraving, the laser is faster and offers superior precision, reducing material waste and enhancing productivity.

– Cost-effective in the long term due to reduced errors and efficient production of custom orders.

Overall, the laser engraver has been a valuable asset, allowing me to create intricate, personalized jewelry efficiently and effectively.

Carlos Johnson –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation. Fast, efficient, and built to last. Highly recommend!”

Klaus Garcia –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls. Fast, efficient, and built to last. Highly recommend!”

Susan Li –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and solidly built—a true 5-star workhorse!”

Joseph Tanaka –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the machine runs efficiently with rapid engraving speeds. Build quality is solid, highly reliable. Five stars!”

Guillermo Novak (verified owner) –

“I used this laser engraver to create custom jewelry tags, and it was surprisingly simple! The precision is amazing, and the results turned out perfect every time.”

Jean Wang –

★★★★★ Excellent Laser Engraver! The engraving precision is impeccable, and the software is intuitive. Fast speeds boost productivity. Sturdy build, reliable performance. Highly recommend!