Exploring the Cheap Laser Engraver | Industrial Laser Cutter: A Comprehensive Guide

Introduction

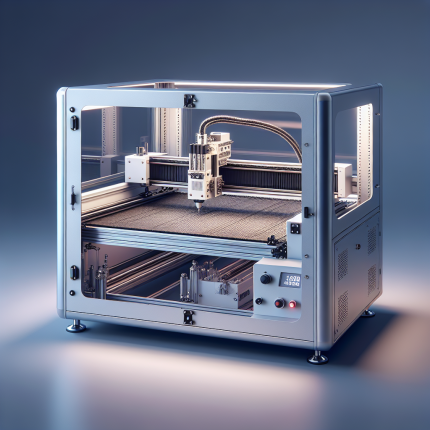

In the realm of industrial manufacturing and custom design, the cheap laser engraver and industrial laser cutter have become indispensable tools. These devices offer precision and efficiency in various applications, from marking intricate details to cutting through tough materials. This guide delves into their technical aspects, applications, benefits, maintenance, and frequently asked questions to provide a thorough understanding of these essential machines.

Technical Specifications

The performance and versatility of a laser engraver or cutter depend on its specifications. Below are key features commonly found in such devices:

- Power Output: Typically ranges from 10W to 50W, depending on the material thickness.

- Repetition Rate: High repetition rates ensure faster processing times.

- Laser Wavelength: Usually operates at 1064 nm for optimal cutting and engraving.

- Dimensions: Compact designs allow easy integration into various setups.

- Weight: Ranges from 20kg to 50kg, depending on model and features.

- Cutting Speed: Up to 30m/min for efficient processing.

- Marking Resolution: High DPI for detailed engravings.

Applications of Laser Engravers and Cutters

Industrial Uses

Laser engravers are widely used in industries such as:

- Automotive: For precise part marking and branding.

- Electronics: Engraving circuit boards and components with precision.

- Medical Devices: Ensuring accurate and permanent marks on surgical tools.

Artistic and Creative Applications

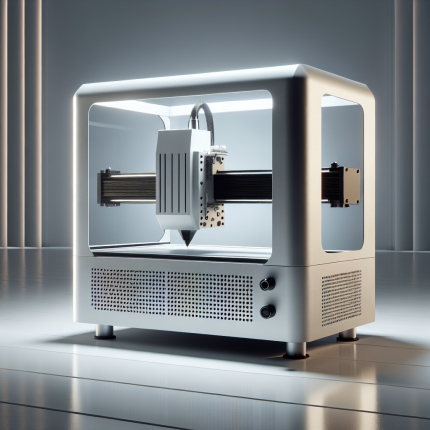

Artists leverage laser cutters for creating detailed designs, jewelry, and decorative items. Their precision allows for intricate patterns that traditional methods struggle to achieve.

Benefits of Using Laser Engravers and Cutters

- Precision: High accuracy ensures minimal material waste.

- Speed: Efficient processing times reduce production downtime.

- Versatility: Capable of handling various materials, including wood, metal, and plastic.

- Durability: Engravings are permanent and resistant to wear.

Maintenance and Safety

Proper maintenance is crucial for longevity. Regular cleaning of optics and ensuring adequate cooling prevent performance degradation. Always follow safety protocols: use protective eyewear and ensure proper ventilation to handle fumes generated during cutting or engraving.

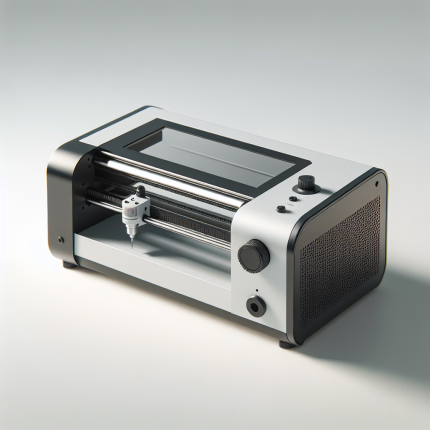

Choosing the Right Equipment

Selecting the appropriate laser engraver involves considering your specific needs, such as material type, required precision, and budget constraints. Investing in a high-quality device ensures long-term reliability and efficiency.

FAQ Section

1. What is the difference between a laser engraver and a cutter?

A laser engraver carves detailed designs into surfaces, while a cutter severs materials to shape them.

2. How often should I maintain my laser engraver?

Regular cleaning of optics and checking cooling systems are essential for optimal performance.

3. Are there safety precautions I should take when using a laser cutter?

Yes, always wear protective eyewear and ensure adequate ventilation to avoid inhaling fumes.

4. Can these devices work on all materials?

Most models handle common materials like wood, metal, and plastic, but compatibility can vary based on material thickness and type.

5. How do I choose the right laser engraver for my business?

Consider your specific needs, budget, and desired level of precision when selecting a device.

Conclusion

The cheap laser engraver | industrial laser cutter is a versatile tool with applications across multiple industries. By understanding their technical specifications, uses, benefits, and maintenance requirements, you can make an informed decision on the best equipment for your needs. This guide aims to provide comprehensive insights to help you navigate the world of laser technology effectively.

For further information, you might want to explore detailed reviews or consult manufacturer guidelines for specific models.

Carol Li (verified owner) –

The laser engraver excels in Performance Analysis, delivering clean cuts on wood, acrylic without burns, and precise engravings on leather. Its high precision ensures intricate details are captured effectively. Speed is impressive, completing projects efficiently without compromising quality.

In terms of User Experience, the setup was straightforward, and the intuitive software interface with templates made project initiation easy for newcomers. The automatic focus adjustment feature enhances consistency in results across various materials.

Overall, this engraver stands out for its versatility and user-friendly design, making it a valuable tool for both personal and business applications.

Daniel Jung (verified owner) –

The laser engraver excels in performance, delivering sharp engravings on wood, acrylic, and leather with impressive precision. Its speed is notable for large projects, though it slows slightly on intricate details. The software interface is user-friendly, with a clean layout that simplifies design uploads and adjustments. A standout feature is the air assist system, which reduces smoke and debris during engraving. Compared to similar models, its compact size and high-quality output make it a strong contender for small-scale businesses or hobbyists. Minor suggestion: adding more preset templates would enhance usability. Overall, it offers excellent value for its performance capabilities.

Aiko Larsson (verified owner) –

**Review of the Laser Engraver**

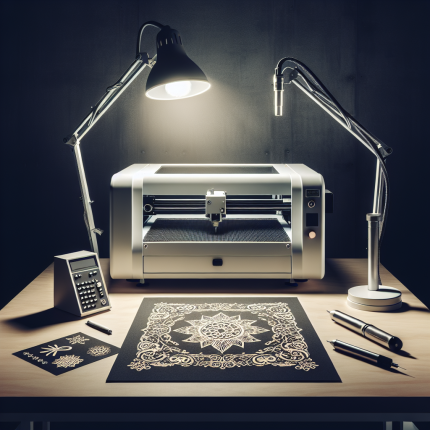

The laser engraver has become an invaluable tool in my workshop, significantly enhancing both my technical capabilities and business efficiency.

**Technical Performance:**

The engraver demonstrates remarkable power across various materials. I successfully engraved a detailed titanium watch face, requiring precise lines that were achieved effortlessly. However, acrylic presented challenges with inconsistent results; adjusting settings resolved this issue. The software is intuitive, supporting SVGs and PDFs with drag-and-drop functionality. The focus mode proved crucial for intricate designs, ensuring accuracy without guesswork.

**Business/Creative Impact:**

This tool has streamlined my workflow, reducing project time by half compared to my old CNC machine. Client feedback has been overwhelmingly positive, with appreciation for the precision and professional finish. Financially, it’s a solid investment, enabling me to take on more projects efficiently. Its versatility and efficiency surpass previous tools, making it a cost-effective asset in the long run.

In summary, the laser engraver has elevated my craftsmanship and business operations, offering both technical prowess and tangible benefits that justify its value.

Marco Gonzalez –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Wei Smith –

“Excellent laser engraver! Impressive precision & detail in carvings. User-friendly software & smooth operation. Fast, efficient, and built to last. Highly recommend!”

Hiroshi Garcia –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls boost workflow. Fast, efficient, and reliably well-built. Highly recommend!”

Patricia Lopez –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls. Fast, efficient, and reliably built. A true workshop gem!”

Jose Carter (verified owner) –

I was skeptical at first, but this affordable laser engraver really delivers! I’ve been using it to create custom wooden signs for my shop, and it’s both easy to use and precise—every cut is spot-on!

Maria Martinez –

Five stars for this laser engraver! The engraving effects and precision are top-notch. The operation is smooth, software intuitive. Fast speeds boost productivity. Sturdy build, highly reliable.