Custom Laser Engraving: A Comprehensive Guide to Laser Engravers for Cups

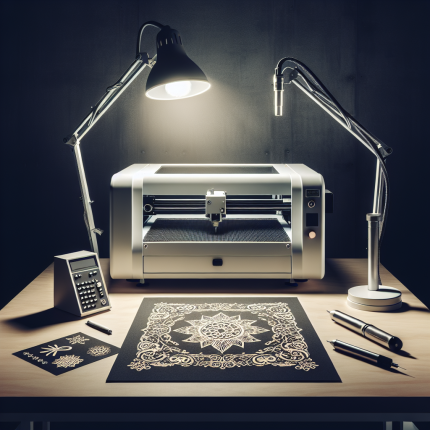

Laser engraving has revolutionized the way we personalize items, offering precision, durability, and creativity. When it comes to custom laser engraving, one of the most popular applications is laser engraving on cups. Whether you’re creating personalized gifts, branding promotional items, or adding a unique touch to everyday objects, a laser engraver for cups is an essential tool. In this guide, we’ll explore everything you need to know about custom laser engraving, focusing on how it works, its benefits, and the technical aspects of using laser engravers for cups.

The Advantages of Laser Engraving for Cups

Laser engraving offers several advantages over traditional methods like screen printing or heat transfer. One of the key benefits is the level of detail that can be achieved. With a laser engraver, you can create intricate designs, logos, and text with unparalleled precision. This makes it ideal for adding custom engravings to cups, whether you’re working on small batches or large-scale projects.

Another advantage is the durability of the engraving. Unlike printed designs, which can fade over time, laser-engraved markings are permanent and resistant to wear and tear. Whether the cup is used daily or subjected to harsh conditions, the engraving remains intact. This makes laser engravers for cups a great choice for both personal and commercial use.

Technical Specifications of Laser Engravers for Cups

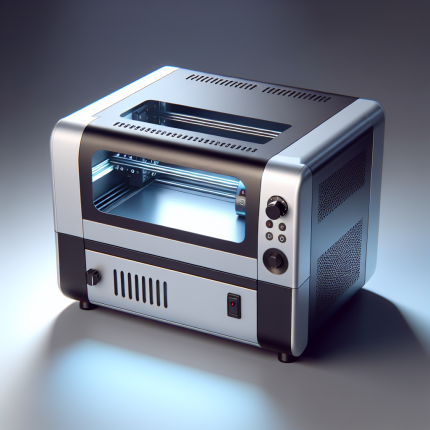

When selecting a laser engraver for cups, it’s important to consider its technical specifications to ensure it meets your needs. Here are some key features to look out for:

- Laser Power: The power of the laser determines how deep and precise the engraving can be. Higher wattage lasers are generally better for thicker materials or darker surfaces.

- Speed Settings: Most laser engravers allow you to adjust the speed, which affects both the quality and efficiency of the engraving process. Slower speeds typically yield higher detail.

- Material Compatibility: Laser engravers work with a variety of materials, including glass, ceramic, stainless steel, and plastic. Check if your engraver is compatible with the types of cups you plan to use.

- Resolution: The resolution of the laser determines the sharpness and clarity of the engraving. Higher resolutions are better for detailed designs.

- Software Integration: Many laser engravers come with software that allows you to create and edit designs, as well as control the engraving process. Some also support importing files from graphic design programs like Adobe Illustrator or CorelDRAW.

How Laser Engraving Works on Cups

Laser engraving works by using a focused beam of light to remove material from the surface of an object. The laser heats the material, causing it to vaporize or burn away, leaving behind a precise and permanent mark. This process is entirely non-contact, which means it won’t damage the surrounding area of the cup.

For cups, the engraving can be applied to various parts, such as the exterior surface, handle, or base. The design is typically created in a vector graphic format before being sent to the laser engraver. The machine then translates the digital design into physical markings on the cup.

Best Practices for Laser Engraving on Cups

To achieve the best results when using a laser engraver for cups, it’s important to follow some basic guidelines:

- Preparation: Clean the surface of the cup thoroughly before engraving to ensure optimal adhesion and visibility of the design.

- Design Selection: Choose designs that are suitable for the material and size of the cup. Avoid overly complex designs that may be difficult to engrave accurately.

- Testing: Always test your design on a spare cup or sample material to check for any issues with alignment, focus, or power settings.

- Post-Engraving Care: After engraving, you can clean the cup with mild soap and water if needed. Avoid abrasive cleaners that may damage the engraving.

Use Cases for Laser Engraved Cups

Custom laser-engraved cups are versatile and can be used in a wide range of applications:

- Personalized Gifts: Engrave names, initials, or meaningful dates on cups to create unique and thoughtful gifts for birthdays, weddings, or other special occasions.

- Promotional Items: Businesses often use laser-engraved cups as promotional items to brand their products or services. These cups are ideal for trade shows, events, or giveaways.

- Custom Branding: Restaurants, cafes, and beverage companies can use laser engraving to add logos, slogans, or nutritional information to their cups.

- Specialty Items: Laser engravers can be used to create decorative or functional items, such as engraved coffee mugs with custom artwork or inspirational quotes.

Frequently Asked Questions (FAQ)

1. Can any type of cup be laser engraved?

Not all cups are suitable for laser engraving. The material plays a crucial role in determining whether the engraving will be visible and durable. Glass, ceramic, stainless steel, and certain types of plastic are ideal candidates for laser engraving. Avoid using cups made from materials that may melt or discolor under the heat of the laser, such as melamine or soft plastics.

2. Is laser engraving safe for food contact?

Yes, laser engraving is safe for food contact. The process doesn’t introduce any harmful chemicals or residues onto the surface of the cup. However, it’s always a good idea to clean the engraved area before first use to ensure hygiene.

3. How long does laser engraving take?

The time required for laser engraving depends on several factors, including the size and complexity of the design, as well as the power and speed settings of the machine. Simple text or small logos can be engraved in just a few minutes, while intricate designs may take longer.

4. Can I remove a laser engraving from a cup?

Once engraved, the markings are permanent and cannot be easily removed without damaging the cup. However, if you’re using a high-powered laser, it’s possible to “re-engrave” over existing markings to create a new design or cover mistakes.

5. How much does it cost to have cups laser engraved?

The cost of laser engraving depends on several factors, including the quantity of cups, the complexity of the design, and the material of the cups. Custom orders may be more expensive than bulk production runs. Contact a professional laser engraving service for an accurate quote based on your specific needs.

Conclusion

Laser engraving is a versatile and effective method for adding custom designs to cups. With its ability to create detailed, permanent markings, it’s no wonder that laser engravers for cups are becoming increasingly popular among hobbyists, businesses, and professionals alike. Whether you’re looking to create personalized gifts, promotional items, or decorative pieces, a laser engraver is a valuable tool to have in your arsenal.

Anders Roberts (verified owner) –

The laser engraver excels in performance on wood, acrylic, and leather, delivering precise cuts and engravings with consistent quality. Its speed is impressive for small to medium projects, such as custom keychains or jewelry tags. The setup process was straightforward, though familiarizing oneself with the software required some time. The interface is user-friendly, with tools like auto-focusing and preset settings streamlining operations. For businesses, it offers excellent ROI due to its versatility in creating both promotional items and personalized art pieces. While the price-performance ratio is favorable, additional safety features could enhance user confidence during high-volume use.

Helga Watanabe (verified owner) –

The laser engraver excels in precision across various materials, delivering sharp engravings on wood without burns, clean cuts on acrylic, and intricate designs on leather. Speed is impressive, completing detailed projects in under 15 minutes. It’s ideal for personal use or small-scale businesses, offering versatility for custom products. The intuitive software enhances workflow, though a minor suggestion is an emergency stop feature for safety. Overall, it’s a reliable tool for artistic and practical applications.

Jun Petrov (verified owner) –

**Laser Engraver Experience Review**

As a craft store owner, integrating the laser engraver into our operations has been transformative. Here’s a focused review highlighting two key aspects: **Specific Project Experience** and **Business/Creative Impact**.

### Specific Project Experience

Our primary use of the laser engraver is with traditional wooden handicrafts, such as cutting intricate patterns in oak and maple. The machine handles these materials effortlessly, producing precise engravings without burning. For instance, when creating a custom cutting board with a detailed floral design, the laser’s precision ensured each petal was sharp and clean.

One challenge we encountered was uneven cuts on softer woods like pine. However, adjusting the laser speed and power resolved this issue, ensuring consistent results across different materials. This adaptability has expanded our product range, allowing us to offer more complex designs with confidence.

### Business/Creative Impact

The laser engraver has significantly streamlined our workflow, reducing production time by up to 40%. This efficiency allows us to take on larger orders without compromising quality. Customers have expressed satisfaction with the precision and detail of our engravings, leading to increased repeat business and referrals.

From a financial standpoint, the investment in the laser engraver has been offset by reduced material waste and faster turnaround times. The ability to handle intricate designs also opens new revenue streams, such as custom orders that command higher prices.

In conclusion, the laser engraver not only enhances our creative capabilities but also strengthens our business operations, making it a valuable asset for both efficiency and customer satisfaction.

Soo Tanaka –

“Exceptional laser engraver! Precise cuts, intuitive software, swift performance, and solid build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Ana Fischer –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation. Fast, efficient, and built to last. Highly recommend!”

Jessica Tanaka –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost efficiency. Sturdy build, reliable performance, and swift engraving speeds make it a 5-star gem!”

Klaus Martinez –

“Exceptional laser engraver! Superb engraving precision and detail, intuitive software, swift operation, and robust build quality. Highly reliable and efficient—a true 5-star experience!”

Melissa Weber (verified owner) –

I got this laser engraver for my small business, and wow, it’s so precise! It made custom jewelry tags a breeze, and now I’m using it for cups too—such a versatile tool!

Jean Anderson –

★★★★★ Exceptional Laser Engraver! The engraving precision is flawless, and the software is user-friendly. Fast speeds boost productivity. Sturdy build, highly reliable. A must-have!