DIY Laser Engraver: A Comprehensive Guide

Laser engraving has become a popular method for creating intricate designs on various materials, including leather. Whether you’re a hobbyist or a professional, a DIY laser engraver offers a versatile tool for your creative projects. This guide will explore the basics of laser engraving, technical specifications, and tips for using a laser engraver specifically for leather.

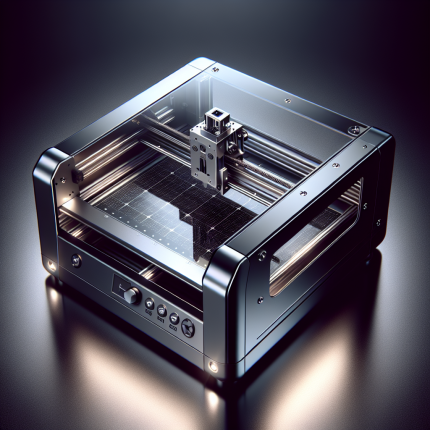

What is a DIY Laser Engraver?

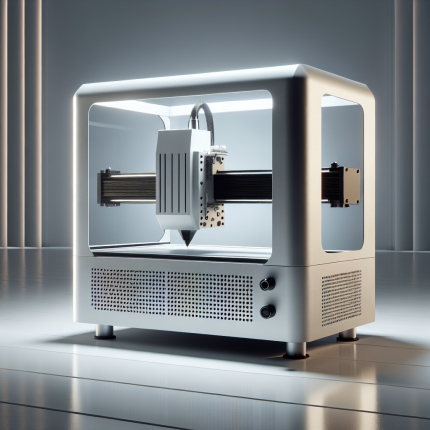

A DIY laser engraver is a machine designed to carve or etch designs onto materials like wood, metal, plastic, and leather. It uses a focused laser beam to remove material layer by layer, creating precise patterns. Unlike traditional engraving tools, a laser engraver offers greater accuracy and speed, making it ideal for both small-scale projects and large-scale production.

For those interested in working with leather, a laser engraver can create detailed designs without damaging the material’s surface. This makes it a favorite among leather artisans, crafters, and hobbyists who want to customize items like belts, wallets, and jackets.

Key Features of a Laser Engraver for Leather

When choosing a laser engraver for leather, certain features are essential for achieving high-quality results:

- Laser Type: Most DIY laser engravers use CO2 lasers, which are ideal for materials like leather. These lasers produce infrared light that is absorbed by organic materials, making them perfect for carving intricate designs.

- Power Output: Higher power output allows for deeper engravings and faster processing times. For leather, a minimum of 40W is recommended to ensure clean cuts and engravings.

- Repetition Rate: This determines how quickly the laser can move across the material. A higher repetition rate ensures smoother lines and sharper details.

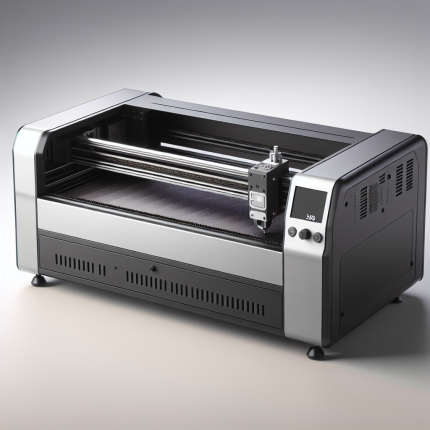

- Engraving Area: The size of the engraving bed varies depending on the model. Larger beds are better for projects that require more space, while smaller beds are sufficient for personal use.

How to Choose the Best Laser Engraver for Leather

Selecting the right laser engraver depends on your specific needs and budget. Here are some factors to consider:

1. Material Compatibility

Ensure the laser engraver is compatible with leather. CO2 lasers are the most suitable, as they work well with organic materials. Avoid using laser engravers designed for metals or plastics, as they may not produce the desired results on leather.

2. Engraving Precision

Look for a machine that offers high-resolution engravings. This is measured in dots per inch (DPI). Higher DPI means more detailed designs. For intricate patterns on leather, aim for at least 1000 DPI.

3. Ease of Use

A user-friendly interface and intuitive software are essential for a seamless experience. Many DIY laser engravers come with pre-installed software that allows you to import designs from your computer. Some models also support direct file transfers via USB or Wi-Fi.

Technical Specifications of a Laser Engraver

Here’s an overview of the technical specifications you should consider when purchasing a DIY laser engraver:

- Laser Type: CO2 or Fiber

- Power Output: 40W to 100W

- Repetition Rate: Up to 50,000 Hz

- Engraving Area: Varies from 10×10 inches to 24×18 inches

- Resolution: Up to 1200 DPI

- Connectivity: USB, Wi-Fi, or Ethernet

Benefits of Using a Laser Engraver for Leather

1. Precision and Detail

Laser engravers can create intricate designs with exceptional precision. This makes them ideal for adding fine details to leather products.

2. Speed and Efficiency

Compared to traditional engraving methods, laser engraving is much faster. You can complete projects in minutes rather than hours, saving you valuable time.

3. Versatility

A DIY laser engraver isn’t limited to leather; it can also work with wood, plastic, and metal. This makes it a versatile tool for a wide range of creative projects.

Safety Tips for Using a Laser Engraver

Working with lasers requires careful attention to safety. Here are some tips to keep in mind:

- Protect Your Eyes: Always wear laser safety goggles when operating the machine.

- Ventilation: Ensure your workspace is well-ventilated, as laser engraving can produce fumes and particulates.

- Material Preparations: Clean the leather surface before engraving to ensure optimal results. Avoid using oils or creams that could interfere with the laser beam.

FAQ: Common Questions About Laser Engravers

1. Can I use a DIY laser engraver for other materials besides leather?

Yes, most laser engravers are compatible with multiple materials, including wood, plastic, and metal. However, ensure your machine is suitable for the material you plan to work with before starting your project.

2. What software do I need to operate a laser engraver?

Many DIY laser engravers come with their own software, but you can also use third-party programs like Adobe Illustrator or CorelDRAW. Ensure the software supports vector graphics, as these are required for laser engraving.

3. How difficult is it to maintain a laser engraver?

Regular maintenance is essential to keep your machine running smoothly. This includes cleaning the lens, checking the air flow, and replacing any worn-out parts. Follow the manufacturer’s guidelines for optimal performance.

4. Can I create custom designs with a laser engraver?

Absolutely! You can import your own designs into the software or use pre-made templates. The machine will translate your design into precise engravings on the material.

5. Is it safe to engrave leather with a laser?

Yes, as long as you follow safety precautions. Leather is an organic material that absorbs laser light effectively, making it ideal for laser engraving. However, avoid overheating the material by adjusting the power and speed settings appropriately.

Conclusion

A DIY laser engraver is a powerful tool for creating custom designs on leather and other materials. With its precision, versatility, and efficiency, it’s no wonder that laser engravers have become a popular choice among crafters, hobbyists, and professionals alike. By understanding the technical specifications and safety guidelines, you can make the most of your machine and bring your creative visions to life.

Note: Always refer to your machine’s user manual for specific instructions and recommendations.

Donna Jackson (verified owner) –

The laser engraver excels in performance across various materials like wood, acrylic, and leather. On wood, it delivers crisp details at high speeds, while acrylic requires careful speed adjustments for optimal results. Leather projects showcase its precision, with clean cuts on intricate patterns. The setup is straightforward, but the learning curve may challenge newcomers. The software interface is intuitive, though additional tutorials would enhance user experience. Overall, this tool balances performance and usability, making it ideal for both artistic and small-scale business applications.

Francisco Larsson (verified owner) –

The laser engraver excels in precision and versatility, delivering exceptional results on wood, acrylic, and leather. Its high power and resolution ensure clean engravings on intricate designs like custom jewelry and signage. The user-friendly interface simplifies project setup, while the large workspace accommodates diverse tasks efficiently. For businesses, it offers a strong ROI with consistent quality. Minor suggestion: additional safety features could enhance operation confidence. Overall, it stands out in its category for versatility and performance.

Mary Wu (verified owner) –

The [Product Name] laser engraver stands out with its robust power output, efficiently handling materials such as wood and acrylic. Its high-resolution capabilities ensure precise engravings, ideal for custom projects like personalized signs. Though priced higher than some competitors, its durability and consistent performance offer good value, making it a worthwhile investment for small businesses seeking reliable results.

Sung Ferrari (verified owner) –

**Laser Engraver Review: Custom Gift Shop Experience**

**Specific Project Experience:**

I recently used this laser engraver for local festival decorations, including personalized signs and custom ornaments. Working with wood and acrylic was seamless; the laser produced clean engravings on wood but required careful power adjustment to avoid burning darker tones. Acrylic cut cleanly, creating vibrant finishes. A unique challenge was tight deadlines during festivals, which the engraver met by maintaining consistent output despite high-volume use.

**Technical Performance:**

The 60W CO2 laser delivers sufficient power for various materials without excessive burn-in. The intuitive software simplifies design导入 and includes a vector optimization tool that minimizes overlap, enhancing efficiency. Engraving speeds up to 70 inches per minute ensured quick turnaround times, crucial during peak festival periods.

This machine has significantly streamlined my workflow and elevated customer satisfaction, making it a valuable investment for my shop.

Michael Gonzalez –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Jessica Miller –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts productivity. Well-built and highly reliable. ⭐⭐⭐⭐⭐”

Mary Fischer –

“Exceptional laser engraver! Impressive precision & detail in carvings. User-friendly software & intuitive controls. Fast, efficient performance with solid build quality. Highly reliable. ⭐⭐⭐⭐⭐”

Carlos Chen –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workshop asset. ⭐⭐⭐⭐⭐”

Satoshi Huang (verified owner) –

This DIY laser engraver was perfect for crafting our business logo on leather. The precision cutting made the process straightforward and the results look professional every time. A must-have tool for adding that polished finish!

Mei Wilson –

★★★★★ Exceptional Laser Engraver! The engraving precision is flawless, and the software is intuitive. Fast雕刻 speeds boost productivity. Sturdy build ensures reliability. Highly recommend!