Engraver Cutter Laser: A Comprehensive Guide to Laser Engraving Machines

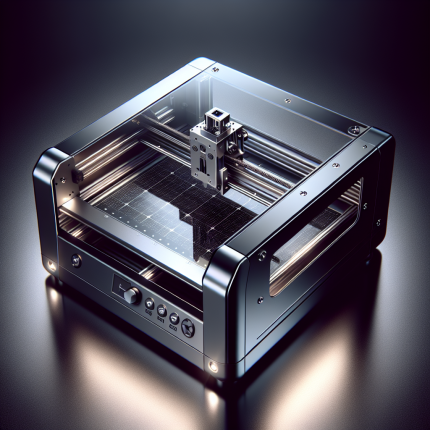

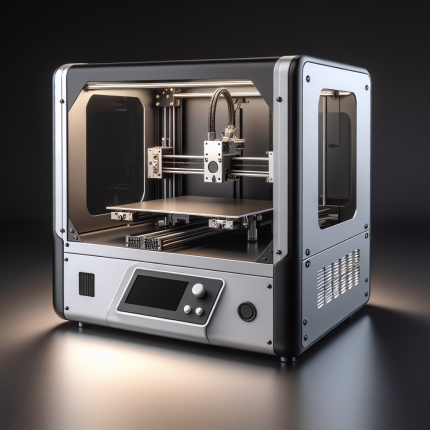

Laser engraving machines have become indispensable tools in various industries, from manufacturing and jewelry making to signage production and custom design. The engraver cutter laser is a specialized tool designed for precision cutting and marking on a wide range of materials, including metals, plastics, wood, and glass. In this guide, we will explore the features, technical specifications, applications, and benefits of laser engraving machines, providing you with a detailed understanding of how these devices work and why they are so valuable in modern manufacturing processes.

Types of Engraver Cutter Lasers

Laser engraving machines come in different types, each suited for specific applications:

- CO2 Lasers: These are the most common type of laser engravers, ideal for cutting and engraving non-metallic materials like wood, plastic, and acrylic. CO2 lasers are known for their high precision and versatility.

- Fiber Lasers: Fiber lasers are more powerful than CO2 lasers and are primarily used for cutting metals. They offer faster processing speeds and higher accuracy, making them a favorite in industrial settings.

- Diode Lasers: Diode lasers are compact and cost-effective, often used for marking or engraving on plastics, glass, and other non-metallic materials.

Technical Specifications of Laser Engraving Machines

When selecting an engraver cutter laser, it is essential to consider the following technical specifications:

- Laser Type: CO2, fiber, or diode lasers determine the range of materials you can work with.

- Power Output: Measured in watts (W), higher power output allows for faster cutting and engraving on thicker materials.

- Repetition Rate: The number of pulses per second determines the speed of the engraving process.

- Beam Quality: Higher beam quality ensures precise cuts and engravings with minimal material damage.

- Control System: Advanced control systems allow for greater precision and customization of engraving patterns.

- Cooling System: Efficient cooling is crucial to prevent overheating during prolonged use.

Applications of Laser Engraving Machines

Laser engraving machines are used in a variety of industries due to their versatility and precision:

- Jewelry Making: Used for creating intricate designs on metals like gold, silver, and platinum.

- Signage Production: Ideal for cutting and engraving signs made from wood, acrylic, or metal.

- Custom Design: Engravers are used to create personalized items such as name tags, plaques, and trophies.

- Industrial Manufacturing: Fiber lasers are widely used in industrial settings for cutting and marking parts on assembly lines.

Advantages of Using Laser Engraving Machines

Laser engraving machines offer several advantages over traditional methods:

- Precision: Lasers provide unmatched accuracy, ensuring that even the most intricate designs are replicated flawlessly.

- Speed: Modern laser engravers can process materials much faster than manual or mechanical methods.

- Versatility: Engraver cutter lasers can work with a wide range of materials, making them suitable for multiple applications.

- Durability: Laser engravings are permanent and resistant to fading or wear, ensuring long-lasting results.

How to Choose the Right Laser Engraving Machine

Selecting the right laser engraving machine depends on your specific needs:

- Material Type: Consider the materials you will be working with most frequently. CO2 lasers are best for non-metallic materials, while fiber lasers excel at cutting metals.

- Budget: Determine your budget and look for machines that offer the best balance of performance and cost.

- Ease of Use: Choose a machine with an intuitive control system to ensure smooth operation, even for less experienced users.

Maintenance and Safety Tips

To maximize the lifespan and efficiency of your laser engraving machine:

- Regularly clean the lens and mirrors to maintain beam quality.

- Follow safety guidelines, including wearing protective eyewear and ensuring proper ventilation in the workspace.

- Schedule routine maintenance checks with a qualified technician to identify and address potential issues early.

FAQ Section

1. What is the difference between an engraver cutter laser and a laser marking system?

An engraver cutter laser is designed for both cutting and engraving, while a laser marking system is primarily used for creating surface markings without cutting through the material.

2. What are the key specifications to consider when buying a laser engraving machine?

Key specifications include laser type, power output, repetition rate, beam quality, control system, and cooling efficiency.

3. Can laser engraving machines be used for industrial applications?

Yes, fiber lasers are widely used in industrial settings for cutting and marking metal parts due to their high power output and precision.

4. How does the cost of a laser engraving machine compare to traditional methods?

While the initial investment in a laser engraver may be higher than traditional tools, the long-term savings in time, material waste, and labor costs make them a cost-effective solution.

5. What materials can I work with using a CO2 laser engraving machine?

CO2 lasers are ideal for cutting and engraving non-metallic materials like wood, plastic, acrylic, and glass.

Conclusion

The engraver cutter laser is a powerful tool that has revolutionized the way we approach precision cutting and engraving. With their versatility, speed, and accuracy, laser engraving machines have become an essential component of modern manufacturing and design processes. By understanding the different types of lasers, their technical specifications, and applications, you can make an informed decision when selecting the right machine for your needs.

Whether you are a jeweler, signmaker, or industrial manufacturer, investing in a high-quality laser engraving machine will undoubtedly enhance your productivity and deliver exceptional results.

Katarina Lee (verified owner) –

The laser engraver excels in processing various materials like wood and acrylic, delivering precise engravings effortlessly. Setup was straightforward, requiring minimal calibration. The intuitive software interface simplifies project management, especially for intricate designs. Compared to competitors, its compact size and efficient cooling system offer practical advantages. While it handles small-scale projects well, a larger workspace would enhance versatility. Overall, it’s a cost-effective choice with solid ROI for hobbyists and small businesses.

Lucia Garcia (verified owner) –

The laser engraver excels in precision and versatility, handling materials like wood, acrylic, and leather with ease. Its high-resolution engravings ensure sharp details, making it ideal for custom projects such as jewelry boxes or signage. The compact design suits home workshops, while its speed supports small-scale production for businesses. However, the software interface could benefit from more intuitive navigation. Overall, it offers excellent value for hobbyists and professionals alike.

Satoshi Huang (verified owner) –

**Experience with Laser Engraver in Product Prototyping**

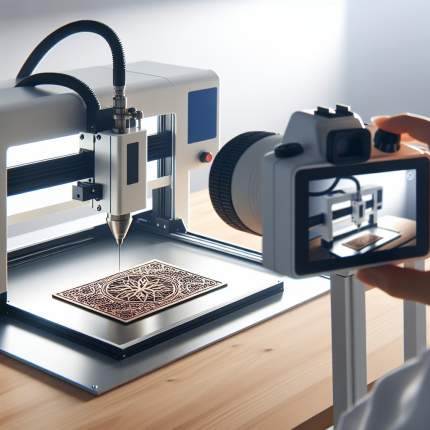

In my work with product prototyping, I’ve utilized a laser engraver primarily for personalized leather goods projects, which highlighted its effectiveness and versatility.

**Project Experience: Personalized Leather Goods**

– **Material Behavior**: Working with various leathers presented unique challenges. The material’s texture and thickness significantly influenced the engraving process. Overly aggressive settings led to burnishing, necessitating careful power adjustments.

– **Challenges Faced**: Ensuring consistent engraving depth across differing leather textures was a hurdle, as softer leathers required precise control to avoid blurring or charring.

– **Solutions Implemented**: Extensive testing on scrap material allowed us to optimize power settings. This trial-and-error approach ensured that each piece received the perfect balance of detail and durability.

– **Results Achieved**: The outcome was remarkable. Intricate designs, such as custom initials on wallets, were executed with precision, impressing clients who appreciated the sharpness and clarity of engravings.

**Technical Performance**

– **Power and Precision**: The laser engraver’s adjustable wattage proved crucial, enabling clean engravings without excessive charring. This feature was pivotal in maintaining the integrity of delicate leather surfaces.

– **Software Experience**: The accompanying software was intuitive, facilitating easy design uploads and adjustments. Its user-friendly interface allowed for quick iterations, enhancing efficiency.

– **Special Features Utilized**: Leveraging vector cutting capabilities, we created precise patterns and logos, adding a professional touch to our leather goods.

**Conclusion**

The laser engraver not only streamlined our workflow but also elevated the quality of our products, resulting in satisfied clients and a positive return on investment. Its technical prowess and adaptability made it an indispensable tool in our prototyping process.

Lars Fischer –

“Exceptional laser engraver! Superb engraving quality and precision, user-friendly software, swift operation, and robust build. Highly reliable and efficient—a true 5-star gem!”

Carlos Miller –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, efficient, and built to last—a true workhorse.”

Soo Li –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts productivity. Well-built and highly reliable. ⭐⭐⭐⭐⭐”

Richard Martin –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls. Fast, efficient, and reliably well-built. Highly recommend!”

Haruki Zhang (verified owner) –

Got this engraver cutter laser, made custom wedding favors for my friend—it was so precise and easy! Love how it turned out.

Sofia Bernard –

Five stars for this laser engraver! The etching is precise and stunning. The operation is smooth, software intuitive. Fast engraving speed boosts productivity. Solid build, highly reliable.