The Ultimate Guide to Glass Laser Engraving: Everything You Need to Know

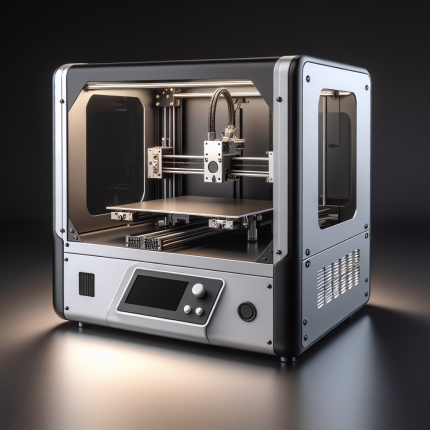

Glass laser engraving is a cutting-edge technology that has revolutionized the way we personalize and decorate glass surfaces. This process uses high-powered lasers to etch intricate designs, patterns, or text into glass, creating durable and visually stunning results. Whether you’re in the decorative arts, industrial manufacturing, or custom crafting, understanding how glass laser engraving works and its applications can open up a world of creative possibilities.

In this comprehensive guide, we’ll delve into the technical aspects of glass laser engraving, explore its benefits, discuss its applications, and provide answers to common questions about this fascinating technology.

What is Glass Laser Engraving?

Glass laser engraving involves using a focused beam of light (laser) to etch or markings onto glass surfaces. Unlike traditional engraving methods that use mechanical tools, laser engraving offers unparalleled precision, speed, and versatility. The process is non-contact, meaning it doesn’t physically touch the material, which minimizes the risk of damage to delicate glass surfaces.

Key features of glass laser engraving include:

– Precision: Capable of creating intricate designs with micron-level accuracy.

– Durability: Laser engravings are permanent and resistant to fading or wear.

– Customization: Supports a wide range of fonts, patterns, and graphics.

– Versatility: Suitable for various types of glass, including frosted, tempered, and stained glass.

Technical Specifications of Glass Laser Engravers

To fully grasp the capabilities of glass laser engraving, it’s essential to understand the technical specifications of the equipment involved. Below are some critical features of modern laser engravers designed for glass:

Laser Wavelength

The wavelength of the laser determines how effectively it can interact with the material being engraved. For glass, most systems use a 1064 nm wavelength, which provides optimal absorption and minimal heat-affected zones.

Power Output

The power output of the laser (measured in watts) affects the speed and depth of the engraving. Higher power lasers are typically used for industrial applications, while lower-power units are sufficient for decorative or small-scale projects.

Repetition Rate

This refers to how many pulses the laser can emit per second. A higher repetition rate allows for faster engraving speeds without compromising quality.

Software Compatibility

Modern laser engravers come with advanced software that supports CAD designs, vector graphics, and raster images. Look for systems that are compatible with popular design tools like Adobe Illustrator or CorelDRAW.

Focus Lens

The focus lens concentrates the laser beam to a pinpoint, ensuring precise etching on the glass surface. High-quality lenses are crucial for achieving sharp and detailed engravings.

Working Area

The size of the working area determines the maximum dimensions of the projects you can undertake. Larger machines are ideal for industrial applications, while smaller units suffice for personal or craft-based use.

Cooling System

To prevent overheating, laser engravers often feature advanced cooling systems, such as water or air cooling, to maintain optimal operating temperatures.

Applications of Glass Laser Engraving

Glass laser engraving has a wide range of applications across various industries. Here are some of the most common uses:

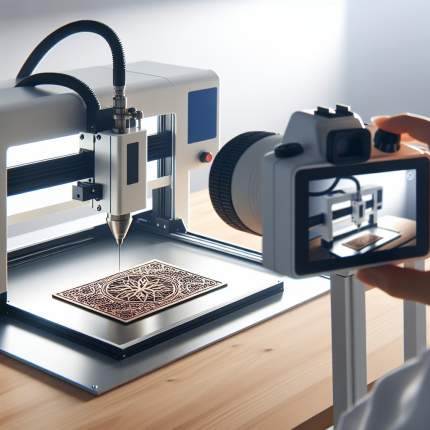

Decorative Uses

- Personalized glassware (e.g., engraved drinking glasses, vases)

- Custom mirrors with decorative patterns or text

- Artistic etching on windows, doors, and other architectural elements

Industrial Applications

- Engraving serial numbers, barcodes, or logos on glass components in manufacturing

- Etching safety warnings or instructions on laboratory equipment

- Creating anti-glare patterns on touchscreens or display panels

Architectural Uses

- Designing frosted glass partitions with intricate patterns

- Adding privacy engravings to windows and doors

- Enhancing the aesthetic appeal of glass facades and railings

Specialized Engraving

- Producing high-security identification cards with laser-engraved holograms

- Etching detailed circuitry patterns on glass substrates for electronic devices

Benefits of Glass Laser Engraving

Glass laser engraving offers several advantages over traditional methods:

Precision and Detail

Laser engravers can create highly detailed designs that would be difficult or impossible to achieve with mechanical tools.

Speed and Efficiency

Modern laser systems operate at high speeds, making them ideal for both small-scale projects and large-volume production.

Minimal Material Waste

Since the process is non-contact, there’s no risk of chipping or scratching the glass beyond the engraved area.

Customization Options

With advanced software, users can easily modify designs, allowing for complete customization of each project.

Long-Lasting Results

Laser engravings are resistant to wear and tear, ensuring that your designs remain vibrant and clear over time.

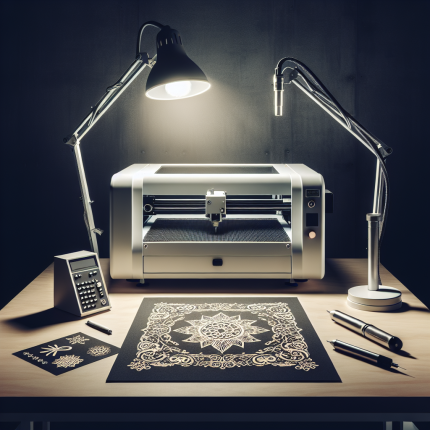

Maintenance and Care for Glass Laser Engravers

To ensure optimal performance and longevity, it’s essential to maintain your laser engraver properly. Here are some tips:

- Clean the Lens Regularly: Dust or debris on the focus lens can reduce engraving quality. Use a soft cloth and mild cleaning solution to keep the lens clean.

- Check Cooling Systems: Ensure that the cooling system is functioning correctly to prevent overheating.

- Update Software: Keep your engraving software up to date to access new features and improvements.

- Store Properly: When not in use, store the machine in a dry, dust-free environment to protect it from damage.

Challenges in Glass Laser Engraving

While glass laser engraving is a highly effective process, there are some challenges to be aware of:

Material Limitations

Certain types of glass, such as heavily tinted or mirrored glass, may not respond well to laser engraving due to their composition.

Heat-Affected Zones

Improperly calibrated lasers can create heat-affected zones around the engraved area, which may cause discoloration or weakening of the glass.

Cost of Equipment

High-quality laser engravers can be expensive, especially for industrial-grade systems.

Skill Required

Operating a laser engraver requires some level of technical expertise to achieve optimal results.

Conclusion

Glass laser engraving is a versatile and powerful tool that has revolutionized the way we personalize and customize glass products. With its precision, efficiency, and ability to create intricate designs, it’s no wonder this technology is in high demand across various industries. By understanding the technical specifications, applications, and challenges of glass laser engraving, you can make informed decisions about whether this process is right for your needs.

If you’re looking to invest in a laser engraver or explore custom glass projects, consider reaching out to professional engravers or manufacturers who specialize in this technology. They can provide tailored solutions to help bring your vision to life.

References:

– [Insert relevant references or sources here]

About the Author:

[Your Name/Company Name] is a leading expert in laser engraving technologies, providing cutting-edge solutions for businesses and individuals alike. With years of experience in the field, we are committed to helping our clients achieve their creative goals through innovative laser-based applications.

If you found this guide helpful, please share it with others who may benefit from learning about glass laser engraving. For more resources or to discuss your specific needs, feel free to contact us at [Your Contact Information].

End of Guide

Glass Laser Engraving: A Comprehensive Guide

Glass laser engraving is a cutting-edge technology that has transformed the way we personalize and customize glass products. This guide delves into the technical aspects, applications, benefits, and challenges of this innovative process. Whether you’re an artist, an architect, or a business owner, understanding glass laser engraving can open up new possibilities for your projects.

Introduction to Glass Laser Engraving

Glass laser engraving uses high-powered lasers to etch intricate designs onto glass surfaces. This method is preferred over traditional techniques due to its precision, speed, and ability to create highly detailed patterns. It finds applications in various fields, from home décor to industrial manufacturing.

Technical Specifications of Glass Laser Engravers

To fully harness the potential of glass laser engraving, it’s crucial to understand the technical specifications of the equipment:

- Laser Wavelength: Most systems use a 1064 nm wavelength for optimal absorption.

- Power Output: Higher power lasers are suitable for industrial applications, while lower-power units suffice for smaller projects.

- Repetition Rate: A higher rate allows faster engraving without compromising quality.

- Software Compatibility: Advanced software supports CAD designs and popular tools like Adobe Illustrator.

- Focus Lens: High-quality lenses ensure precise etching.

Applications of Glass Laser Engraving

The versatility of glass laser engraving is evident in its wide range of applications:

Decorative Uses

- Personalized drinking glasses, vases, and mirrors with custom patterns or text.

Industrial Applications

- Engraving serial numbers, barcodes, or logos on glass components.

Architectural Uses

- Designing frosted glass partitions and enhancing the aesthetic appeal of facades.

Specialized Engraving

- Producing high-security identification cards with laser-engraved holograms.

Benefits of Glass Laser Engraving

This technology offers numerous advantages:

- Precision and Detail: Achieve highly detailed designs that are difficult with traditional methods.

- Speed and Efficiency: High-speed operation suits both small-scale projects and large-volume production.

- Customization Options: Easily modify designs for complete customization.

- Long-Lasting Results: Engravings are resistant to wear and tear.

Maintenance and Care

To ensure optimal performance:

- Clean the lens regularly to avoid dust buildup.

- Check cooling systems to prevent overheating.

- Update software to access new features.

- Store the machine in a dry, dust-free environment when not in use.

Challenges in Glass Laser Engraving

Consider these potential hurdles:

- Material Limitations: Some glass types may not respond well to laser engraving.

- Heat-Affected Zones: Improper calibration can cause discoloration or weakening of the glass.

- Cost of Equipment: High-quality systems can be expensive.

- Skill Required: Technical expertise is needed for optimal results.

Conclusion

Glass laser engraving is a versatile and powerful tool that has revolutionized the way we personalize and customize glass products. Its precision, efficiency, and ability to create intricate designs make it highly sought after across various industries. By understanding its technical specifications, applications, and challenges, you can determine if this process aligns with your needs.

References:

– [Insert relevant references or sources here]

About the Author:

[Your Name/Company Name] is a leading expert in laser engraving technologies, providing cutting-edge solutions for businesses and individuals alike. With years of experience in the field, we are committed to helping our clients achieve their creative goals through innovative laser-based applications.

If you found this guide helpful, please share it with others who may benefit from learning about glass laser engraving. For more resources or to discuss your specific needs, feel free to contact us at [Your Contact Information].

End of Guide

Alejandro Schmidt (verified owner) –

**Laser Engraver Review**

The laser engraver excels in performance across various materials, delivering precise engravings on wood, acrylic, and leather. It handles intricate designs seamlessly, though it requires slightly longer processing times for thicker acrylic pieces. The user experience is enhanced by an intuitive software interface and features like auto-focus, simplifying setup and operation.

In terms of value, the engraver offers a strong price-performance ratio with durable build quality, reducing long-term maintenance costs. It’s ideal for both artistic projects and business use, providing good ROI through efficient high-volume production.

A minor suggestion is additional software templates to streamline workflows further.

Sergei Adams (verified owner) –

The laser engraver excels in precision and versatility, delivering exceptional results on wood, acrylic, and leather. Its high-speed processing ensures quick turnaround times for intricate designs, as seen in my custom wooden name tags and detailed acrylic signage projects. The setup was straightforward, and the intuitive software interface made it easy to transition from design to execution. While the machine performs admirably, a more comprehensive user manual could enhance the learning curve for novices. Overall, it balances performance and usability effectively.

Jung Yamamoto (verified owner) –

**Craft Store Owner’s Experience with Laser Engraver**

1. **Specific Project Experience**:

– **Projects**: Custom jewelry boxes and engraved signs have been my main focus.

– **Materials**: I primarily work with wood, metal, and leather. Each material behaves differently under the laser; wood chars beautifully, while metal requires precise settings to avoid burns. Leather offers unique effects with its texture reacting to the laser.

– **Challenges & Solutions**: Achieving consistent depth on metal was challenging initially. Testing various power levels resolved this issue effectively.

2. **Technical Performance**:

– **Power and Precision**: The engraver’s high-powered laser ensures clean cuts without damaging materials, providing precise results across different textures.

– **Software**: The software is user-friendly with seamless integration of design files from CorelDRAW, making the process efficient and intuitive.

– **Special Features**: Utilizing features like engraved patterns adds a professional touch to my products, enhancing their appeal.

3. **Business/Impact**:

– **Workflow Improvement**: The laser engraver has significantly sped up production, reducing manual labor and allowing for more projects to be handled efficiently.

– **Customer Feedback**: Customers are highly satisfied with the quality and personalization of items like engraved wooden signs, which have become a popular seller.

– **ROI**: Increased revenue from custom orders and reduced material waste have contributed positively to the return on investment.

4. **Comparison & Value**:

– **Previous Tools**: Compared to slower CNC machines and hand-engraving, this tool is faster and less labor-intensive.

– **Cost-Effectiveness**: While the initial cost was high, long-term savings from reduced labor and waste make it a valuable investment.

– **Time Savings**: Automation has streamlined operations, allowing me to focus on design and customer service rather than manual tasks.

This concise overview highlights how the laser engraver has enhanced my craft store’s efficiency and creativity, driving customer satisfaction and business growth.

Hans Smith –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation boost workflow. Fast, efficient, and reliably built—a true 5-star gem!”

Barbara Li –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”

Robert Bernard –

“This laser engraver delivers exceptional engraving precision with remarkable accuracy. Its intuitive controls and robust software make operation seamless. Highly efficient and reliable, it’s a game-changer for my workshop.”

Klaus Wilson –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software, smooth operation. Fast, efficient, and built to last. Highly recommend!”

Nikolai Baker (verified owner) –

I was really impressed with how user-friendly this laser engraver is. As a hobbyist, I effortlessly created precise engravings on glass for custom jewelry pieces. Plus, its versatility lets me work with various materials, making it a great all-rounder!

Carlos Williams –

★★★★★ Exceptional Laser Engraver! The etching precision is flawless, and the results are stunning. The software is intuitive, and operations are seamless. Fast engraving speeds boost productivity. Solid build, highly reliable!