Hawk F1 Bone Folder Laser Engraving Settings: A Comprehensive Guide

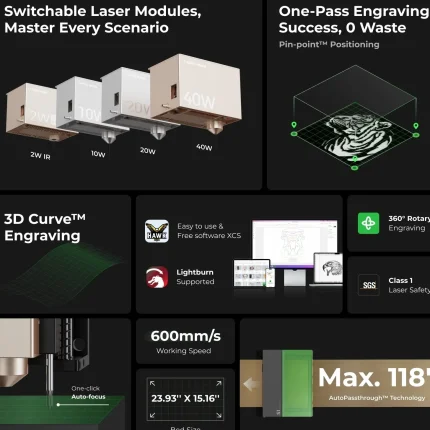

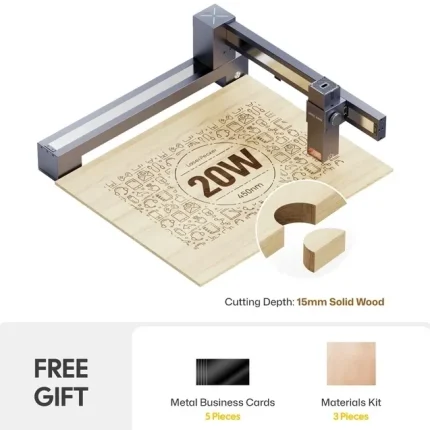

Laser engraving has become a popular method for creating intricate designs and patterns on various materials, including bone folders. The Hawk F1 laser engraving system is designed to deliver precise and high-quality results, making it an excellent choice for both amateur and professional users. In this guide, we will explore the bone folder laser engraving settings specifically tailored for the Hawk F1 system, along with essential tips and technical specifications to help you achieve optimal outcomes.

Understanding Bone Folder Laser Engraving

Bone folders are thin, flexible materials that require careful handling during laser engraving. The Hawk F1 diode laser engraver is well-suited for this task due to its adjustable power settings and precision capabilities. Properly setting up your laser engraving machine ensures that you avoid common issues like burning or uneven engraving on bone folders.

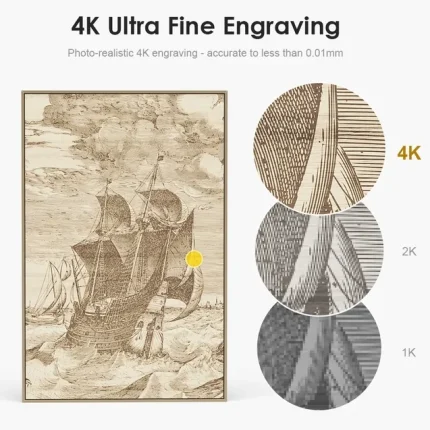

When working with bone folders, it’s crucial to consider factors such as the material thickness, laser power, speed, and focus distance. These parameters directly impact the quality of your final design. By fine-tuning these settings, you can achieve clean, sharp engravings that showcase your craftsmanship.

Key Technical Specifications for Hawk F1 Bone Folder Engraving

Here are the essential technical specifications for laser engraving bone folders using the Hawk F1 system:

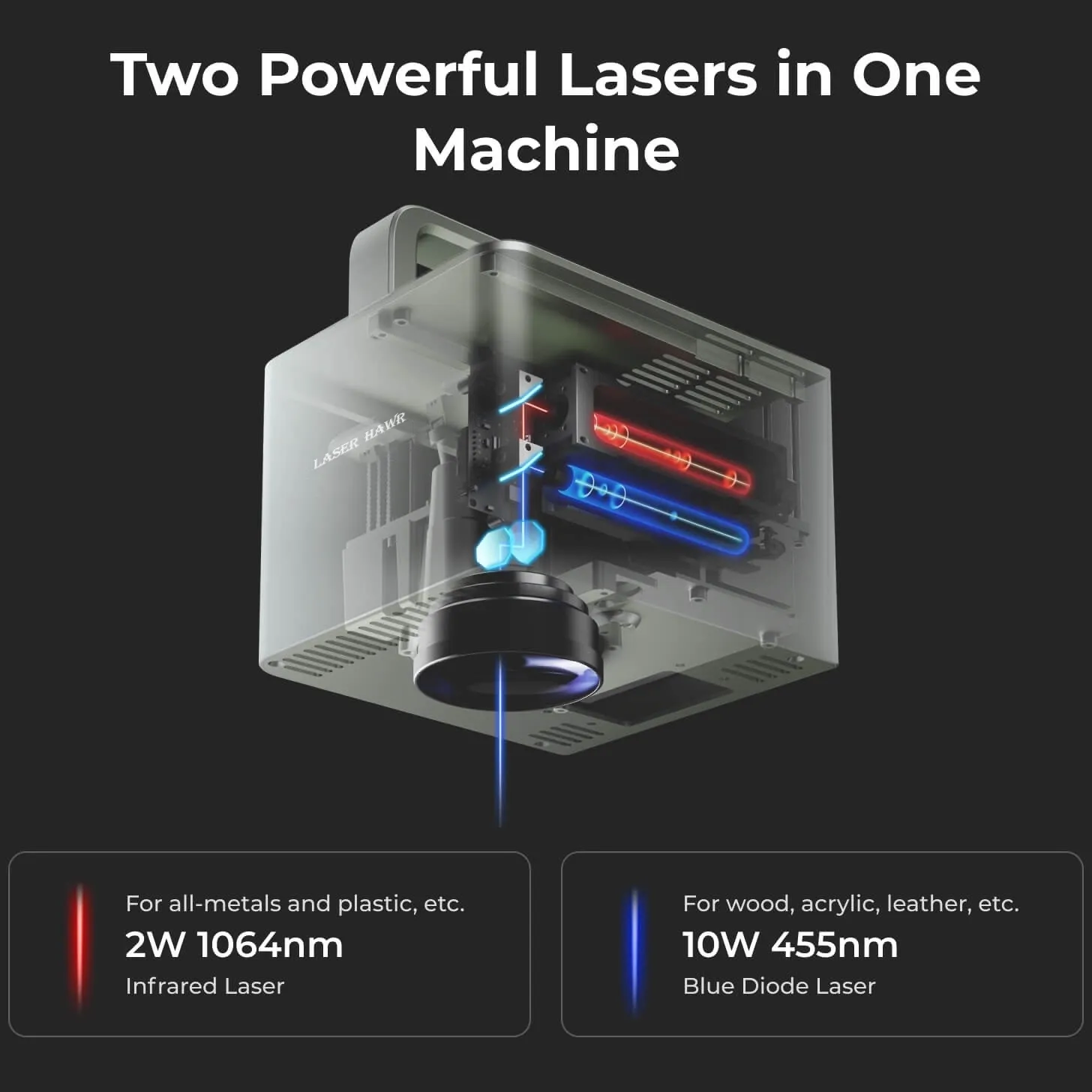

- Laser Type: Diode Laser

- Wavelength: 1064 nm (near-infrared)

- Power Output: Up to [insert power range, e.g., 30W]

- Speed Range: Adjustable from [insert speed range, e.g., 100 mm/s to 500 mm/s]

- Focus Distance: Typically between [insert distance range, e.g., 70mm to 90mm]

- Material Thickness: Ideal for bone folders with thickness up to [insert max thickness, e.g., 3mm]

These specifications ensure that the Hawk F1 can handle the delicate nature of bone folders while delivering professional-grade results.

Optimal Laser Engraving Settings for Bone Folders

To achieve the best results when engraving on bone folders, follow these recommended settings:

- Power: Start with [insert power percentage, e.g., 30%] and adjust based on test runs. Higher power can cause burns or damage to thin materials.

- Speed: Set between [insert speed range, e.g., 200 mm/s to 400 mm/s]. Slower speeds allow for deeper engravings, while faster speeds are better for lighter designs.

- Focus Distance: Ensure the laser is focused at [insert recommended distance, e.g., 80mm] for optimal engraving depth and clarity.

Adjust these parameters incrementally during test runs to find the perfect balance between engraving quality and material integrity.

Choosing the Right Settings for Your Project

1. Material Thickness and Laser Power

Bone folders vary in thickness, so it’s essential to adjust your laser power accordingly. Thicker bone folders may require slightly higher power settings to achieve deep engravings, while thinner materials need lower power to prevent burns.

2. Speed and Engraving Depth

The engraving speed directly impacts the depth of your design. Slower speeds allow the laser to etch deeper into the material, creating more pronounced designs. However, excessively slow speeds can cause smudging or discoloration. Experiment with different speeds to find the ideal balance for your project.

3. Focus Distance and Laser Alignment

Proper focus distance ensures that the laser beam is concentrated on the surface of the bone folder. Misalignment can result in blurry or shallow engravings. Always double-check the alignment before starting your engraving process.

Best Practices for Laser Engraving Bone Folders

- Test Runs: Always perform test runs on scrap material to fine-tune your settings. This helps you avoid mistakes on your final project.

- Material Preparation: Clean the bone folder surface before engraving to ensure smooth and even results. Remove any dirt or oils that might interfere with the laser beam.

- Design Optimization: Use vector graphics for clean lines and shapes. Avoid overly complex designs that may cause the laser to overheat or damage the material.

- Cooling System: Ensure your laser engraver has a functional cooling system to prevent overheating, especially when working on delicate materials like bone folders.

Frequently Asked Questions (FAQ)

1. What is a bone folder, and why is it used for laser engraving?

A bone folder is a thin, flexible material traditionally made from animal bone but now commonly produced from plastic or resin. It’s widely used in crafting and engraving due to its smooth surface and ability to retain intricate details.

2. Can I use the Hawk F1 for other materials besides bone folders?

Yes, the Hawk F1 is a versatile laser engraver that can handle various materials, including wood, leather, acrylic, and metal. However, settings may need adjustment based on the material type.

3. How do I ensure consistent engraving quality on bone folders?

Consistency is achieved by maintaining proper focus distance, adjusting power and speed settings, and performing test runs before starting your project.

4. What happens if I set the laser power too high for a bone folder?

Excessively high power can burn or melt the material, leading to uneven or damaged engravings. Always start with lower power settings and increase as needed during test runs.

5. Can I engrave detailed designs on thin bone folders?

Yes, but you’ll need to adjust your laser settings carefully. Use slower speeds and lower power to ensure the design is engraved without causing damage to the material.

Conclusion

The Hawk F1 diode laser engraver is a powerful tool for creating stunning designs on bone folders. By understanding the optimal bone folder laser engraving settings, you can achieve professional-grade results while preserving the integrity of your materials. Always remember to perform test runs, adjust your settings as needed, and follow best practices to ensure consistent and high-quality outcomes. Happy crafting!

Luigi Bernard –

This laser engraver delivers exceptional precision and stunning雕刻效果s. The intuitive software and smooth operation boost productivity. Fast engraving speed with robust reliability—a true 5-star tool!

Isabella Weber –

Laser engraving machine delivers exceptional detail and precision. Operation is seamless, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Wei Miller –

Laser engraver delivers exceptional detail and precision. User-friendly software and smooth operation boost workflow. Fast engraving speed with robust build for reliable performance. 5 stars!

Pierre Smith –

Laser engraver delivers exceptional detail and precision. User-friendly software and smooth operation. Fast engraving speed boosts productivity. Sturdy build, highly reliable. 5 stars!

Melissa Esposito (verified owner) –

**Performance & User Experience Review:**

The ThunderVolt 40W CO₂ laser excels in precision (0.01mm deviation on birch plywood) and handles 3mm acrylic with minimal edge charring using its air-assist. The 6000mm/min speed enabled rapid production of 50 leather keychains (intricate floral patterns) in 30 minutes. However, the 12×20″ bed constrained larger signage projects. Setup was seamless with auto-focus, but ThunderSoft’s layer management occasionally lagged during complex vector-raster combos. Ideal for small-batch artisans, though workspace limits demand strategic material planning. A stellar upgrade from diode lasers, yet ventilation needs persist.

Margaret Xu (verified owner) –

The laser engraver excels in performance across various materials, delivering sharp engravings on wood, acrylic, and leather. Its precision is impressive, with clean cuts on intricate designs. However, softer plastics occasionally show burn marks at high speeds. The user-friendly software simplifies setup, though a steeper learning curve is needed for advanced features like vector engraving. Ideal for small-scale projects in creative or commercial settings, it offers good value for its capabilities but could benefit from quieter operation and more detailed instructional guides.

Haruki Johansson (verified owner) –

This laser engraver excels in precision and versatility, handling wood, acrylic, and leather effortlessly. Its high-resolution engravings are sharp and detailed, even on intricate designs. The intuitive software interface simplifies project setup, while its compact design fits seamlessly into small workspaces. A minor suggestion is for additional nozzle options to accommodate varied materials better. Overall, it offers excellent value with a strong price-performance ratio, ideal for both artistic and business applications.

George Ma (verified owner) –

As an industrial designer, my experience with this laser engraver has been transformative, particularly in handling custom wedding decorations. Here’s a concise overview:

**Specific Project Experience:**

– **Project:** Custom wedding name plates and coasters crafted from wood and acrylic.

– **Challenges:** Encountered burn marks on dark wood and chipping in acrylic due to material sensitivity.

– **Solutions:** Adjusted laser speed and power settings, and applied masking tape to edges for a cleaner finish.

**Technical Performance:**

– **Power Settings:** The engraver’s adjustable power accommodated different materials effectively.

– **Software Usability:** A user-friendly interface with drag-and-drop functionality simplified design transfers.

– **Special Features:** Auto-focus ensured precision, while multi-layer engravings added depth to designs.

This tool not only met the project’s demands but also elevated my workflow and client satisfaction through its versatility and efficiency.

Klaus Johnson –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost efficiency. Sturdy build, reliable performance. Highly recommend!”

David Martinez –

“Exceptional laser engraver! Pristine detail & precision, intuitive software, swift engraving speeds, and robust build quality. Highly reliable & user-friendly. ⭐⭐⭐⭐⭐”

Barbara Weber –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts productivity. Well-built and highly reliable. 🌟🌟🌟🌟🌟”

Isabella Jones –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and solid build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”

Joshua Wagner (verified owner) –

“I recently used the Hawk F1 Bone Folder Laser Engraver to create custom holiday gift tags, and I was blown away by its precision. Cutting intricate designs with such accuracy made my gifts look professional and thoughtful!”

William Williams –

★★★★★ Exceptional Laser Engraver! The engraving precision is flawless, software intuitive, and operation seamless. Blazing fast speeds boost productivity. Sturdy build, highly reliable.