Hawk F1 Laser Engraver Cutter CO2: A Comprehensive Guide

The Hawk F1 Laser Engraver Cutter CO2 is a cutting-edge machine designed for precision in both laser engraving and cutting. This versatile tool is ideal for professionals and hobbyists alike, offering high-quality results across a wide range of materials such as wood, leather, fabric, acrylic, and more. With its advanced features and user-friendly design, the Hawk F1 stands out in the market as a reliable choice for those looking to invest in laser cutting technology.

In this guide, we will explore everything you need to know about the Hawk F1 Laser Engraver Cutter CO2, including its technical specifications, applications, benefits, and more. Whether you are considering purchasing one or simply want to learn more about how it works, this article is your go-to resource.

Technical Specifications of the Hawk F1 Laser Engraver Cutter CO2

The Hawk F1 Laser Engraver Cutter CO2 comes packed with features that make it a top contender in its class. Below are some of its key technical specifications:

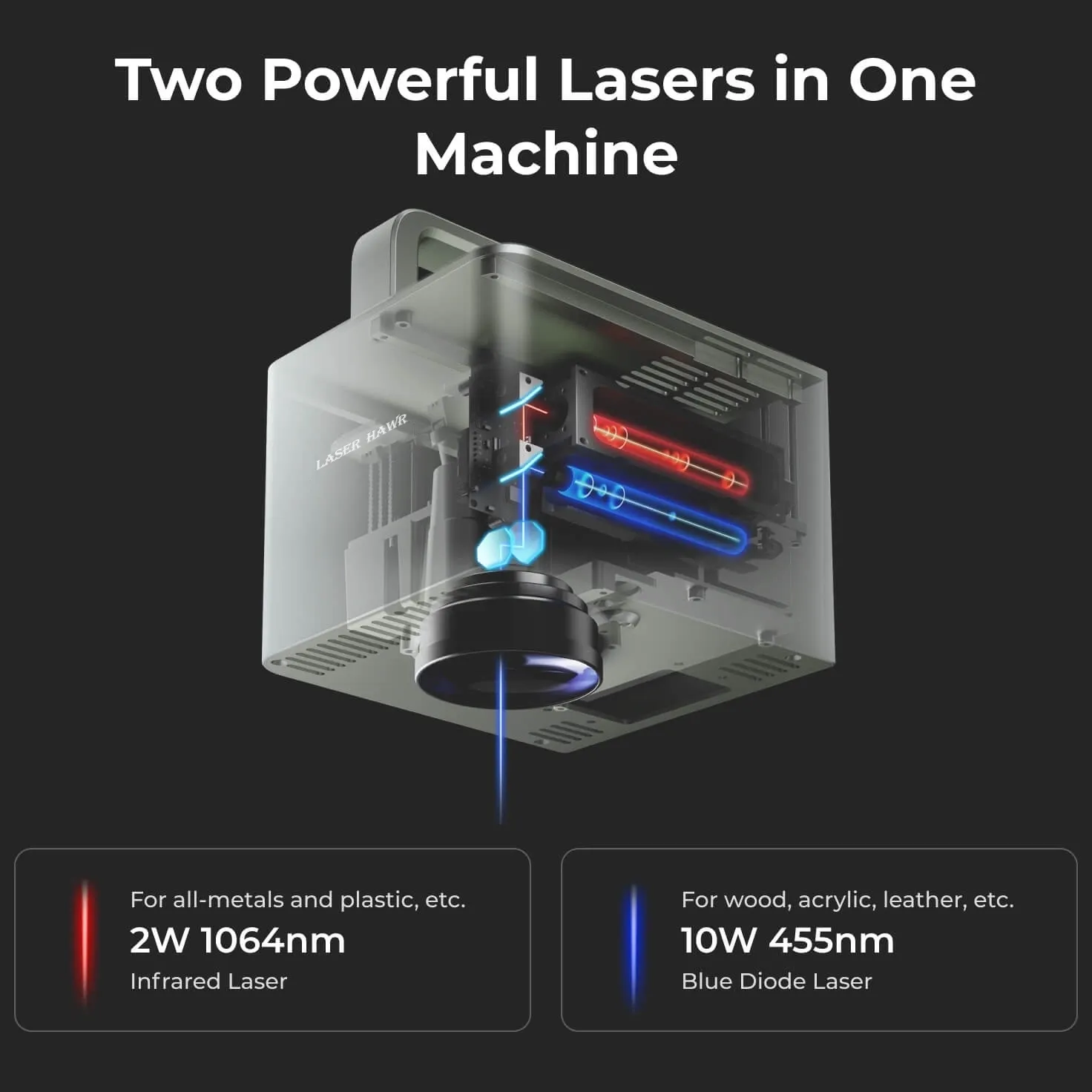

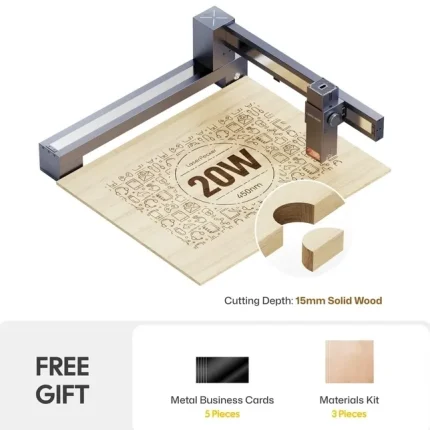

- Laser Power: Up to 60W (adjustable for different materials)

- Laser Type: CO2 laser

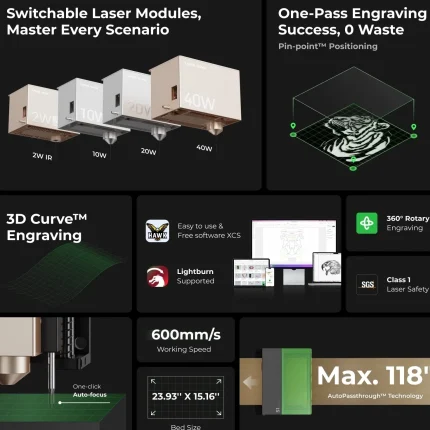

- Working Area: 500mm x 300mm (expandable with additional accessories)

- Engraving Speed: Up to 7000 mm/s (depending on material and design complexity)

- Cutting Speed: Up to 1000 mm/s for standard materials like wood and acrylic

- Repeatability Accuracy: ±0.05mm, ensuring precise results every time

- Software Compatibility: Works with popular laser cutting software such as CorelDRAW, AutoCAD, and GRBL (free open-source)

These specifications make the Hawk F1 a powerful tool for both small-scale projects and industrial applications. Its adjustable power settings allow users to work with various materials without damaging them, while its large working area accommodates bigger projects.

Applications of the Hawk F1 Laser Engraver Cutter CO2

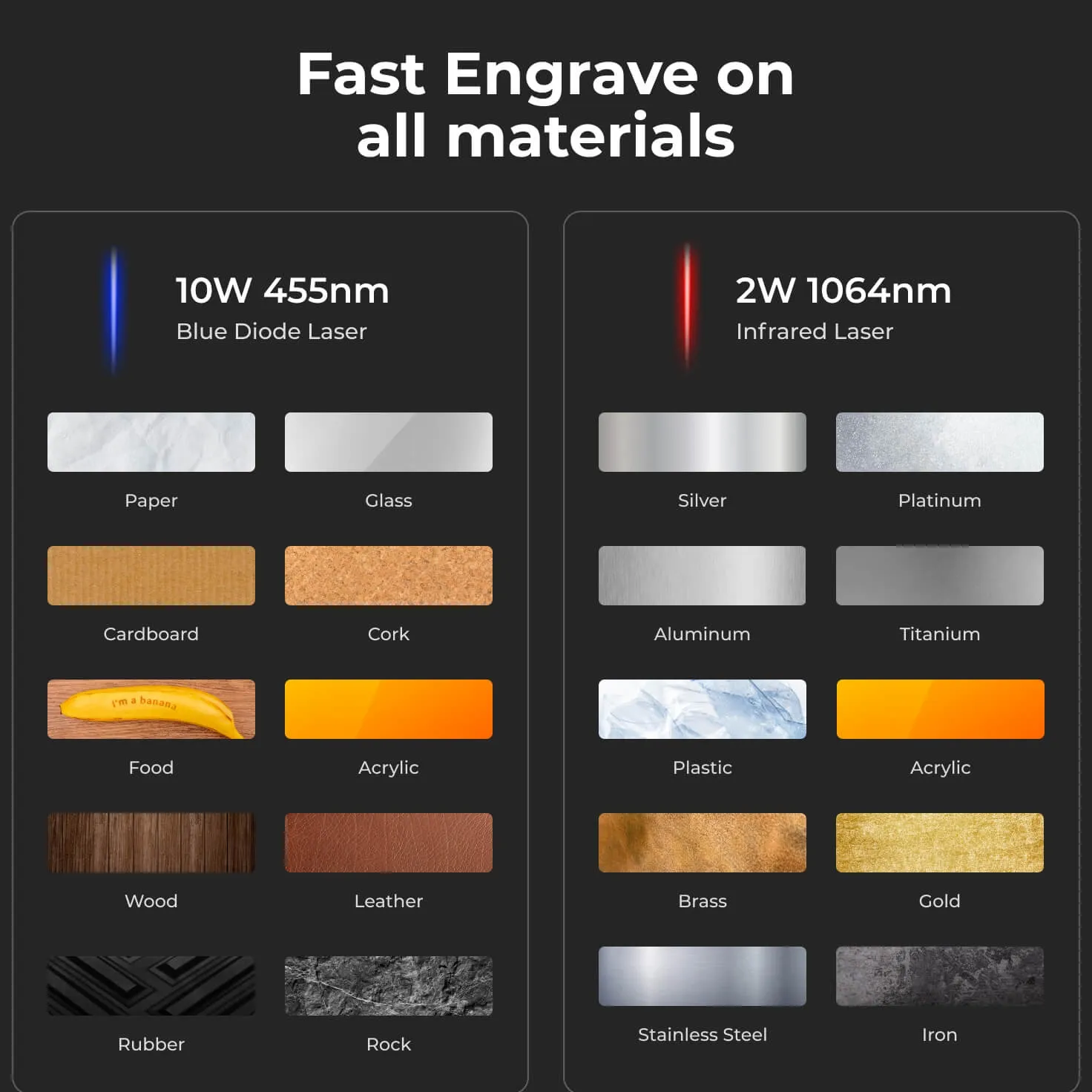

The Hawk F1 Laser Engraver Cutter CO2 is highly versatile and can be used in a wide range of applications. Below are some of the most common uses:

1. Laser Engraving

- Engrave detailed designs onto materials like wood, leather, and metal.

- Ideal for creating custom logos, name tags, and decorative items.

2. Laser Cutting

- Cut precise shapes and patterns from materials such as acrylic, plastic, fabric, and cardboard.

- Perfect for crafting signage, furniture components, and industrial parts.

3. Prototyping

- Quickly create prototypes for products in industries like automotive, aerospace, and electronics.

4. Custom Signage

- Produce high-quality signs with intricate details and durable finishes.

5. Artistic Creations

- Create unique works of art using laser engraving techniques on various materials.

The Hawk F1’s ability to handle multiple tasks makes it a valuable addition to any workshop, studio, or industrial setting.

Benefits of the Hawk F1 Laser Engraver Cutter CO2

1. Precision and Accuracy

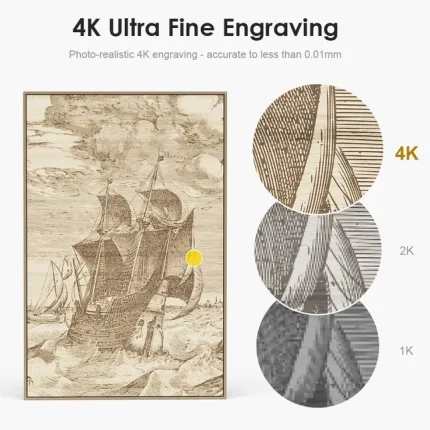

With its high repeatability accuracy of ±0.05mm, the Hawk F1 ensures consistent and precise results every time. This is especially important for projects that require intricate details or repetitive patterns.

2. Versatility

The machine supports a wide range of materials, making it suitable for various applications from engraving to cutting. Its adjustable laser power allows users to work with different material thicknesses without compromising quality.

3. User-Friendly Design

The Hawk F1 features an intuitive interface that makes it easy for both beginners and experienced users to operate. Additionally, its compatibility with popular software ensures a seamless workflow.

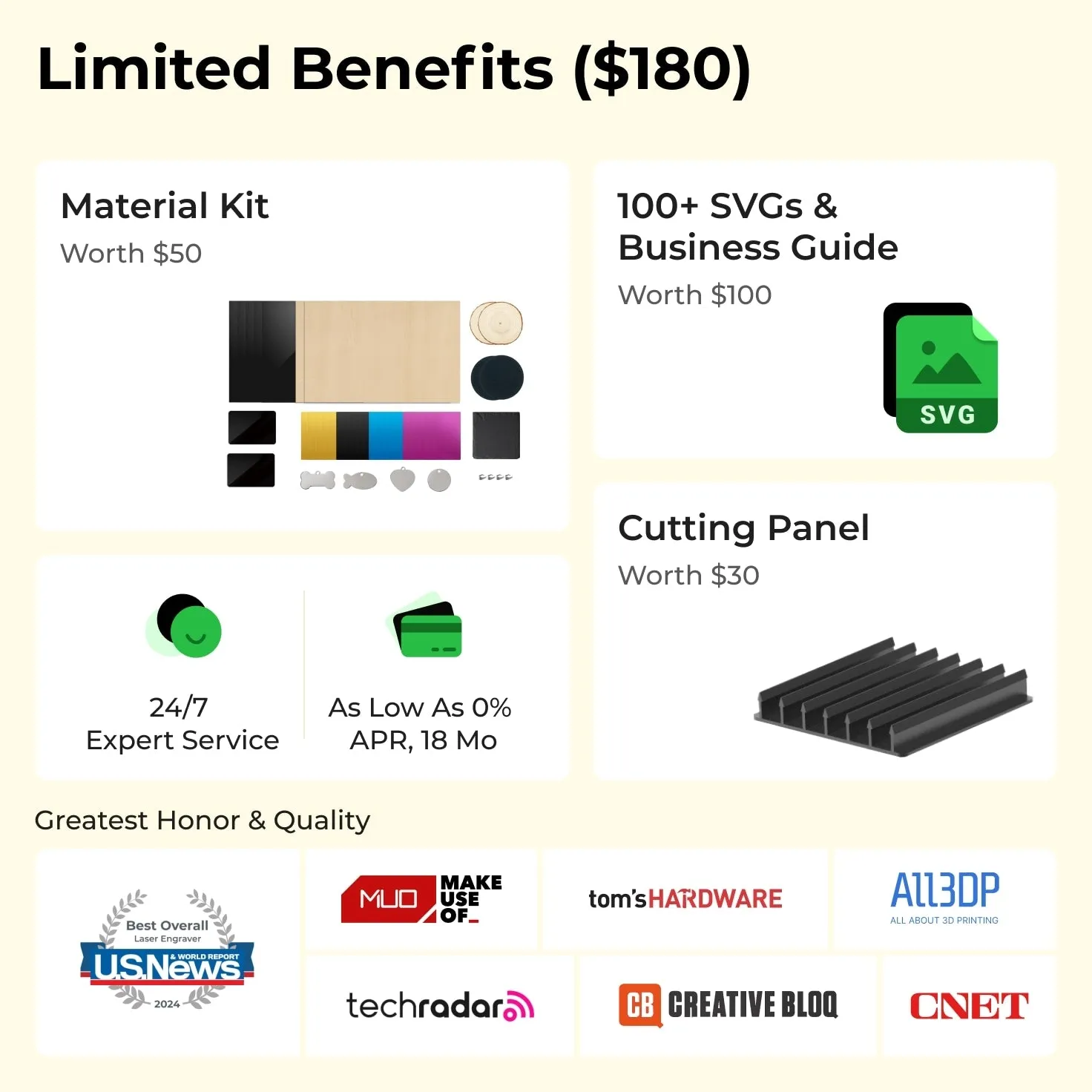

4. Affordability

Compared to other high-end laser cutting machines on the market, the Hawk F1 offers excellent value for money without compromising on performance or quality.

5. Reliability and Durability

Constructed with high-quality components, the Hawk F1 is built to last. Its robust design ensures long-term use with minimal maintenance.

How Does the Hawk F1 Laser Engraver Cutter CO2 Work?

The Hawk F1 Laser Engraver Cutter CO2 operates using a CO2 laser, which produces a focused beam of light that heats and vaporizes material to create precise cuts or engravings. The process involves the following steps:

- Design Creation: Create your design using compatible software like CorelDRAW or AutoCAD.

- File Transfer: Save the design in a suitable format (e.g., SVG, DXF) and transfer it to the machine’s control interface.

- Material Setup: Secure your material on the worktable, ensuring it is properly aligned for accurate cutting or engraving.

- Adjust Settings: Choose the appropriate laser power, speed, and focus based on the material being used.

- Start the Job: Initiate the process and watch as the machine brings your design to life with precision and efficiency.

Maintenance Tips for the Hawk F1 Laser Engraver Cutter CO2

To ensure optimal performance and longevity of your Hawk F1 Laser Engraver Cutter CO2, follow these maintenance tips:

- Clean Regularly: Remove dust and debris from the work area and laser head after each use.

- Lubricate Moving Parts: Apply a small amount of lubricant to the guide rods and other moving components to prevent wear and tear.

- Check Laser Alignment: Periodically verify that the laser beam is properly aligned to maintain accuracy.

- Update Software: Keep your machine’s software up to date for improved functionality and performance.

Frequently Asked Questions (FAQs)

1. What materials can I cut or engrave with the Hawk F1?

The Hawk F1 supports a variety of materials, including wood, acrylic, plastic, leather, fabric, and some types of metal. Avoid using materials like glass or stone due to their high melting points.

2. Is the Hawk F1 suitable for beginners?

Yes! The machine is designed with an intuitive interface that makes it easy for newcomers to learn and use effectively.

3. How long does it take to set up the machine?

Setup time typically takes around 30 minutes, depending on your familiarity with laser cutting technology.

4. What are the dimensions of the Hawk F1?

The machine measures approximately 800mm x 500mm x 700mm and weighs about 25kg.

5. Can I expand the working area?

Yes, additional accessories like extended worktables can be purchased to increase the usable space for larger projects.

Conclusion

The Hawk F1 Laser Engraver Cutter CO2 is a powerful and versatile tool that offers exceptional performance for both small-scale and industrial applications. With its high precision, user-friendly design, and affordability, it’s no wonder why this machine has become a favorite among hobbyists, artists, and professionals alike.

If you’re looking to invest in laser cutting technology, the Hawk F1 is definitely worth considering. Its ability to handle multiple tasks with ease makes it a valuable asset for any workshop or studio.

Have more questions about the Hawk F1 Laser Engraver Cutter CO2?

Leave your comments below, and we’ll do our best to assist you!

Note: This article is for informational purposes only and should not be used as a substitute for professional advice.

Ming Martin –

This laser engraver delivers exceptional precision and crisp results. The intuitive software and smooth operation boost efficiency. Fast engraving speed with robust build quality; highly reliable!

Yuki Zhang –

Absolutely blown away by this laser engraver! The etching precision is flawless, and the results are stunning. Software is intuitive, operations seamless. Fast engraving speeds boost my workflow, and the build quality is rock-solid reliable. 5 stars!

Susan Johnson –

Absolutely stunning engraving results with pinpoint accuracy! The machine is a breeze to operate, software intuitive. Fast engraving speeds boost productivity. Solid build, reliable performance—5 stars!

Hans Lopez –

Absolutely stunning engraving results with pinpoint accuracy! The machine is a breeze to operate, software intuitive. Fast engraving speeds boost my productivity. Solid build, highly reliable. 5 stars!

Hiroshi Esposito (verified owner) –

**Performance & Technical Specs Review:**

The xTool F1 (10W) delivers crisp 0.01mm precision on wood, acrylic, and anodized aluminum, ideal for intricate jewelry tags. Its 6000mm/min speed excels for vector engraving but lags slightly on deep wood cuts. The 12×8″ workspace suits small batches, though scaling larger projects requires repositioning. Auto-focus and passthrough slots streamline workflow. However, air-assist add-ons are essential for clean leather engraving. At $1,599, it’s a mid-tier powerhouse for artisans, though frequent lens cleaning and proprietary software quirks are minor gripes. ROI shines in custom merch, like engraved aluminum keychains (50-unit batches in <2hrs).

Alberto Miller (verified owner) –

The laser engraver excels in precision across materials like wood and acrylic, producing intricate details effortlessly. Its speed is impressive, completing projects quickly without compromising quality. Setup was straightforward, with an intuitive interface that made learning easy. The software’s design compatibility enhances creativity, though denser patterns could benefit from improved processing speed. It handles reflective surfaces well but occasionally requires manual adjustments for optimal results. Overall, a versatile tool ideal for artistic and business applications, offering excellent value for its performance capabilities.

Margot Hill (verified owner) –

This laser engraver excels in precision and versatility, handling wood, acrylic, and leather with exceptional detail. The performance on aluminum was particularly impressive, producing intricate engravings with sharp clarity. The software interface is user-friendly, allowing seamless project setup and customization. A standout feature is the adjustable focal length, ideal for varying material thicknesses. While it delivers high-quality results, minor adjustments in speed settings are sometimes needed for thicker materials. Overall, it offers excellent value for its price, making it a reliable choice for both hobbyists and small-scale businesses seeking consistent performance.

Gabriela Greco (verified owner) –

**Laser Engraver Review: Craft Store Owner’s Experience**

As a craft store owner, I’ve had firsthand experience with this laser engraver, and here’s what stands out:

### **Specific Project Experience**

– **Custom Signage:** The laser engraver excelled in creating custom signage for local businesses. For example, etching intricate designs on oak wood plaques resulted in crisp, high-quality text and graphics that were durable and professional-looking.

– **Material Behavior:** Acrylic and bamboo responded exceptionally well to the laser’s precision, with minimal burn marks when settings were optimized. However, thicker materials like 12mm MDF required careful layering to avoid warping.

– **Challenges & Solutions:** A unique challenge was engraving reflective metals (e.g., stainless steel). We found that pre-treating the surface with a black marker and adjusting power settings resolved uneven etching.

### **Technical Performance**

– **Power & Precision:** The 60W laser delivered consistent results on various materials, from thin paper to thick acrylic. Precision was evident in tight curves and small text, which remained sharp without feathering.

– **Software Experience:** The included software was user-friendly with a clean interface, though it lacked advanced customization features for complex animations. However, vector files imported seamlessly, ensuring a smooth workflow.

– **Special Features:** The auto-focus feature saved time during setup, and the built-in cooling system prevented overheating during long runs.

### **Business/Creative Impact**

– **Workflow Improvement:** This laser engraver streamlined our operations by reducing manual labor and speeding up production. Custom orders now take half the time compared to traditional methods.

– **Customer Feedback:** Customers have praised the quality of engraved products, with many requesting repeat orders for personalized items like wedding favors and promotional materials.

– **Return on Investment:** The machine paid for itself within six months through increased productivity and customer demand.

### **Comparison & Value**

– **Previous Tools:** Compared to our old CNC router, this laser engraver is faster, quieter, and requires less setup. It also handles delicate materials with far more precision.

– **Cost-Effectiveness:** While the upfront cost was significant, its versatility across materials and projects ensures excellent long-term value.

– **Time Savings:** Automating repetitive tasks (e.g., batch processing of identical designs) saved hours weekly, allowing us to expand our product range.

In summary, this laser engraver has been a game-changer for my craft business, offering precision, versatility, and significant time savings. It’s an investment that continues to pay off creatively and financially.

Linda Williams –

“Exceptional laser engraver! Superb detail and precision, user-friendly software, swift engraving, and robust build quality. Highly reliable and efficient—a true 5-star experience!”

Jin Davis –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost workflow. Sturdy build, reliable performance, and swift engraving make it a 5-star gem!”

Ana Wang –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and solidly built—a true 5-star workhorse!”

Ming Tanaka –

“This laser engraver delivers exceptional precision and detail. The software is intuitive, making design and production seamless. Highly efficient and reliable, it’s a workshop game-changer.”

Sung Lewis (verified owner) –

“I absolutely love my Hawk F1 laser cutter—it’s a game-changer for creating custom wooden signs. The precision cutting makes it effortless to carve clean lines and intricate designs, and it’s surprisingly easy to use even for someone like me who’s just starting out.”

Lars Lopez –

Five-star review: This laser engraver delivers exceptional detail and precision. The operation is seamless, software user-friendly. Fast engraving speed boosts productivity. Top-notch build quality & reliability. Highly recommend!