Laser Cutter Acrylic | Wood Laser Engraving Machine: A Comprehensive Guide

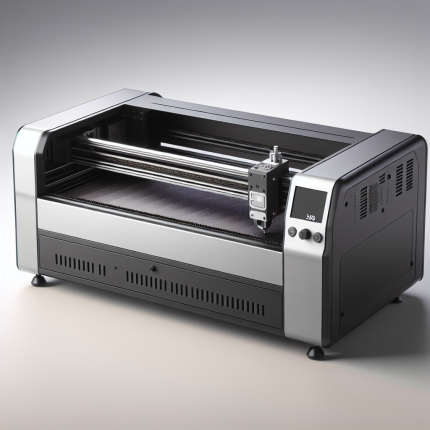

Laser cutter acrylic machines and wood laser engraving machines have become indispensable tools for hobbyists, artists, and professionals alike. These precision-cutting devices allow users to create intricate designs, patterns, and engravings with remarkable accuracy. Whether you’re working on small-scale projects or large industrial applications, a high-quality laser engraving machine can transform your creative vision into reality. This guide will explore the features, technical specifications, and uses of these machines, helping you understand their capabilities and benefits.

Technical Specifications of Laser Cutter Acrylic & Wood Engraving Machines

Before diving into the applications of laser cutter acrylic and wood engraving machines, it’s essential to understand their technical specifications. These details will help you determine whether a particular machine meets your project requirements:

- Laser Power Output: Typically ranges from 10W to 100W, depending on the intended use. Higher power output is ideal for cutting thicker materials like wood or acrylic.

- Laser Type: Most machines use CO2 lasers, which are highly effective for cutting and engraving non-metallic materials. Fiber lasers are another option but are more commonly used for metal.

- Cutting Speed: Varies depending on material thickness and design complexity. High-quality machines can achieve speeds of up to 1000mm/s.

- Precision: Laser cutter acrylic and wood engraving machines offer exceptional accuracy, with typical resolutions ranging from 1200 dpi to 4800 dpi.

- Material Compatibility: These machines are designed to work with a variety of materials, including acrylic, wood, leather, plastic, glass, and more.

- Software Compatibility: Many laser engraving machines support popular design software like CorelDRAW, Adobe Illustrator, and AutoCAD, making it easy to transfer designs to the machine.

Applications of Laser Cutter Acrylic & Wood Engraving Machines

Laser cutter acrylic and wood engraving machines are incredibly versatile tools with a wide range of applications:

1. Custom Design Work

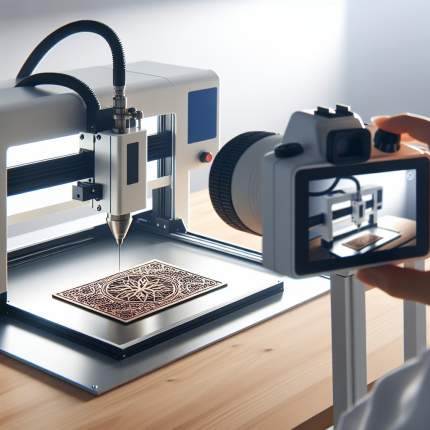

Artists and designers often use these machines to create custom pieces, such as engraved wooden signs, decorative acrylic panels, and personalized gifts. The ability to produce intricate designs with precision makes them ideal for creative projects.

2. Industrial Uses

In industrial settings, laser cutter acrylic and wood engraving machines are used for cutting and engraving large-scale components. For example, they can be employed in the manufacture of furniture, signage, and decorative panels.

3. Prototyping and Model Making

Engineers and product developers use these machines to create prototypes and models quickly and accurately. The ability to work with various materials makes them a valuable tool in the prototyping process.

4. Educational Purposes

Laser cutter acrylic and wood engraving machines are also used in educational settings, such as schools and universities, to teach students about laser technology and its applications.

Maintenance and Safety Tips for Laser Cutter Acrylic & Wood Engraving Machines

Proper maintenance is crucial to ensure the longevity and performance of your laser cutter acrylic or wood engraving machine. Here are some tips to keep in mind:

- Regular Cleaning: Dust and debris can accumulate on the machine’s optics, reducing its efficiency. Clean the lenses and mirrors regularly using compressed air or specialized cleaning solutions.

- Cooling System Maintenance: Laser machines generate heat during operation, so it’s essential to maintain their cooling systems to prevent overheating. Check the coolant levels and ensure proper airflow around the machine.

- Software Updates: Keep your machine’s software up to date to access the latest features and improvements. Regular updates can enhance performance and compatibility with new materials or design software.

- Safety Precautions: Always wear protective eyewear when operating a laser cutter acrylic or wood engraving machine. Ensure the work area is well-ventilated, as some materials release fumes during cutting or engraving.

Frequently Asked Questions (FAQs)

1. What materials can a laser cutter acrylic and wood engraving machine work with?

Laser cutter acrylic and wood engraving machines are designed to work with non-metallic materials such as acrylic, wood, plastic, leather, glass, and more. They are not suitable for cutting or engraving metal without specialized equipment.

2. How easy is it to learn how to use a laser cutter acrylic machine?

Most laser cutter acrylic machines come with intuitive software and user-friendly interfaces, making them relatively easy to learn. However, some basic training or tutorials may be required to master advanced features.

3. What are the advantages of using a laser engraving machine over traditional methods?

Laser engraving offers several advantages, including higher precision, faster processing times, and the ability to create complex designs that would be difficult to achieve manually. Additionally, laser engraving leaves no physical marks on the material, resulting in cleaner and more polished finishes.

4. Can I use a laser cutter acrylic machine for both cutting and engraving?

Yes, most laser cutter acrylic machines are capable of both cutting and engraving. The same machine can be used to cut through materials like acrylic or wood and create detailed engravings on the surface.

5. How much does it cost to maintain a laser cutter acrylic and wood engraving machine?

Maintenance costs vary depending on the machine’s size, complexity, and usage frequency. Regular maintenance, such as cleaning and software updates, can help extend the lifespan of your equipment and reduce long-term costs.

Conclusion

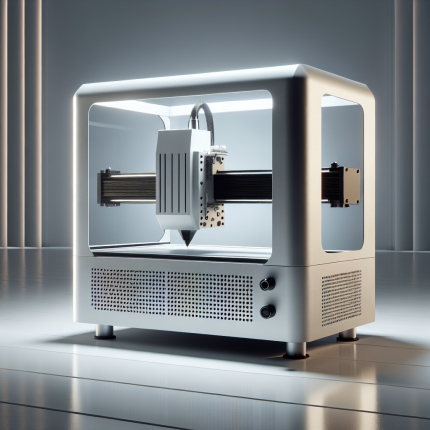

Laser cutter acrylic and wood engraving machines are powerful tools that combine precision, versatility, and efficiency to meet a wide range of cutting and engraving needs. With their ability to work with various materials and create intricate designs, these machines have become essential for artists, hobbyists, and professionals alike. By understanding the technical specifications, applications, and maintenance requirements of these devices, you can make informed decisions about whether they are right for your projects.

If you’re considering purchasing a laser cutter acrylic or wood engraving machine, it’s important to research different models and compare their features to find the one that best suits your needs. Whether you’re working on small-scale creative projects or large industrial applications, these machines offer unparalleled performance and versatility.

Paolo Novak (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering clean engravings on wood and consistent rastering on acrylic. Its precision is impressive for intricate designs, though speed could improve for large projects. The 1200 DPI resolution ensures sharp details, while the 50W laser power handles deep engravings without burning. The software interface is user-friendly, with intuitive controls for adjusting settings. A minor suggestion: adding an optional enclosure for dust control during wood or leather engraving would enhance its practicality.

Dorothy Hernandez (verified owner) –

The laser engraver excels in versatility, delivering crisp results on wood, acrylic, and leather with consistent precision. Setup was straightforward, though some assembly required attention to detail. The software interface is intuitive, offering customizable settings that enhance project flexibility. It outperforms competitors in speed and accuracy, making it ideal for both artistic endeavors like custom jewelry and business applications such as signage production. While the price-performance ratio is favorable, minor improvements like enhanced dust extraction could further elevate its value.

Claudia Olsson (verified owner) –

**Laser Engraver Review: Custom Trophy Manufacturer’s Perspective**

**Specific Project Experience:**

Our experience with the laser engraver has been transformative, especially when working with engraved metal trophies. The machine handles different metal thicknesses seamlessly, allowing intricate details even on thicker materials. One challenge was achieving consistent finishes on polished surfaces without causing discoloration, which we resolved by adjusting the pulse frequency and speed settings for each material type.

**Technical Performance:**

The engraver’s precision is remarkable, capturing fine details that enhance our trophy designs. The software offers customization options, enabling creative adjustments to font styles and image clarity, which has expanded our design possibilities. We particularly appreciate how quickly it processes metals compared to other materials, reducing production time significantly.

**Business/Creative Impact:**

The laser engraver has revolutionized our workflow by allowing faster turnaround times for large orders, freeing up staff for other tasks. Our customers are thrilled with the precision and creativity in designs, leading to positive feedback and repeat business. This investment has not only boosted efficiency but also opened doors to new client opportunities.

**Comparison & Value:**

Compared to manual engraving tools, this laser system reduces human error and increases consistency, ensuring high-quality results every time. It outperforms traditional methods by offering faster speeds and superior detail accuracy, making it a cost-effective solution that quickly justified its investment through operational efficiencies.

In summary, the laser engraver has been an invaluable asset, enhancing our creative output and business operations while delivering exceptional customer satisfaction.

Carlos Li –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”

Jose Lee –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Mary Kim –

“This laser engraver delivers exceptional precision and detail. The software is intuitive, making design and execution seamless. Highly recommend for its efficiency and reliability.”

Barbara Miller –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and efficient. ⭐⭐⭐⭐⭐”

Luigi Hoffmann (verified owner) –

This laser cutter is super accurate and a breeze to use! I created some business logo signs with intricate details, and they turned out perfectly—even as a newbie. It’s fantastic for hobbyists aiming for professional results without hassle.

Jin Miller –

Five-star review: This laser engraver delivers exceptional etching precision and clarity. The operation is smooth, software user-friendly. Fast engraving speed boosts productivity. Top-notch build quality, highly reliable.