Laser Engraved Tumblers and Laser Engraving Cutting Machines: A Comprehensive Guide

Laser engraved tumblers have become a popular choice for those seeking durable, personalized, and high-quality drinking vessels. These tumblers are created using advanced laser engraving cutting machines, which offer precision and versatility in crafting intricate designs. In this guide, we’ll explore the features of laser engraved tumblers, the technical specifications of laser engraving cutting machines, and how these tools contribute to creating unique and long-lasting products.

The Benefits of Laser Engraved Tumblers

Laser engraved tumblers are ideal for both personal use and commercial applications due to their numerous advantages:

- Customization: Laser engraving allows for highly detailed and personalized designs, making each tumbler a one-of-a-kind piece.

- Durability: Unlike printed or painted designs, laser engravings are permanent and resistant to fading or wear over time.

- Aesthetic Appeal: The precision of laser engraving ensures that even the most complex patterns are rendered with clarity and sharpness.

- Versatility: Laser engraved tumblers can be used for a variety of purposes, including as wedding favors, promotional items, or everyday drinkware.

Technical Specifications of Laser Engraved Tumblers

Understanding the technical aspects of laser engraved tumblers is essential for selecting the right product for your needs:

- Material Options: Most laser engraved tumblers are made from high-quality glass, stainless steel, or ceramic, ensuring both durability and elegance.

- Engraving Depth: The depth of the engraving can vary depending on the machine used, but most designs are deep enough to be easily visible while maintaining a smooth texture.

- Design Flexibility: Laser engraving machines allow for intricate designs, including text, logos, patterns, and even photographs, making them suitable for a wide range of applications.

- Care Instructions: While laser engraved tumblers are durable, they should be cleaned with care to avoid scratching the surface.

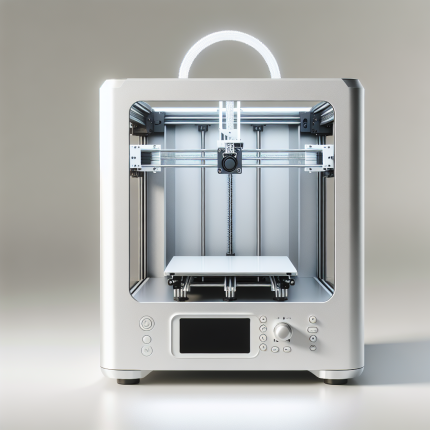

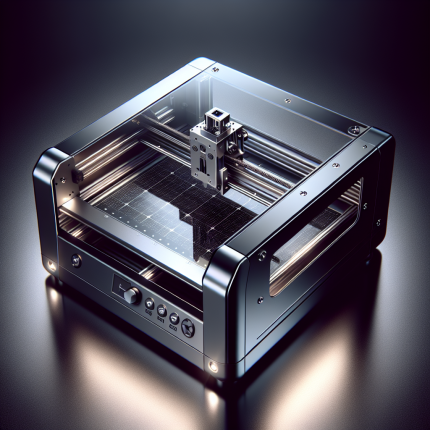

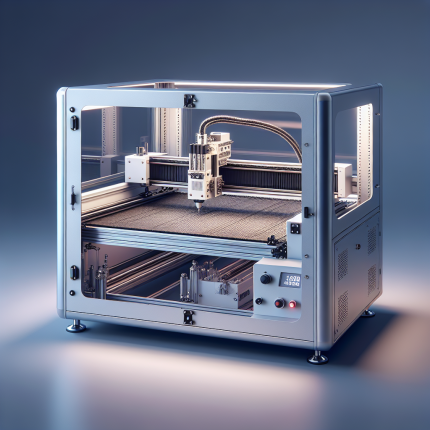

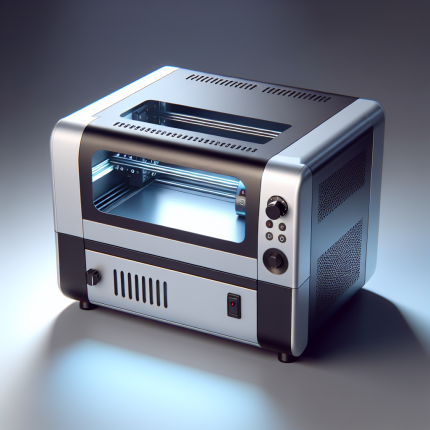

Exploring Laser Engraving Cutting Machines

Laser engraving cutting machines are the backbone of creating high-quality laser engraved tumblers. These machines use focused laser beams to etch designs into materials with precision and accuracy. Below are some key features and specifications of these machines:

- Precision: Modern laser engraving machines can achieve a level of detail that is unmatched by traditional engraving methods, ensuring crisp and clear designs.

- Speed: Despite their precision, these machines are also fast, making them suitable for both small-scale projects and large-volume production runs.

- Compatibility: Laser engraving cutting machines are compatible with a variety of materials, including glass, metal, wood, and plastic, offering versatility in design options.

- Adjustable Power Settings: These machines come with adjustable power settings, allowing users to control the depth and intensity of the engraving based on the material being used.

Applications of Laser Engraved Tumblers

Laser engraved tumblers have a wide range of applications across different industries:

- Weddings and Events: Personalized laser engraved tumblers are popular as favors for weddings, anniversaries, and other special occasions.

- Promotional Items: Businesses use laser engraved tumblers as promotional items to showcase their logo or brand message.

- Custom Gifts: These tumblers make unique gifts for individuals who appreciate personalized and high-quality products.

- Household Use: Many people opt for laser engraved tumblers as a stylish addition to their home decor, with designs that reflect their personality or interests.

How Laser Engraving Cutting Machines Work

Understanding the process behind creating laser engraved tumblers can help you appreciate the technology involved:

- Design Creation: The first step involves creating the design using specialized software. This design is then converted into a format compatible with the laser engraving machine.

- Material Selection: Depending on the desired outcome, the user selects the appropriate material for the tumbler—such as glass or stainless steel.

- Engraving Process: The laser beam is directed at the material, etching the design into the surface with precision. The power and speed of the laser can be adjusted to achieve the desired depth and detail.

- Finishing Touches: After engraving, the tumbler may undergo additional finishing processes, such as polishing or applying a protective coating, to enhance its appearance and durability.

Frequently Asked Questions (FAQ)

1. What is the difference between laser engraving and traditional engraving?

Laser engraving uses a focused beam of light to etch designs into materials, offering higher precision and versatility compared to traditional engraving methods, which often rely on mechanical tools.

2. Can laser engraved tumblers be used in the dishwasher?

Yes, most laser engraved tumblers are dishwasher-safe. However, it’s important to avoid abrasive detergents or scrubbing brushes that could potentially scratch the surface.

3. What materials are best for laser engraving?

Laser engraving works well on a variety of materials, including glass, stainless steel, aluminum, wood, and plastic. The choice of material depends on the desired aesthetic and functionality of the tumbler.

4. How long does it take to engrave a design on a tumbler?

The time required for laser engraving depends on the complexity of the design and the size of the tumbler. Simple text or logos can be engraved in just a few minutes, while intricate designs may take longer.

5. Are laser engraving cutting machines difficult to operate?

While some knowledge of design software is helpful, modern laser engraving machines are user-friendly and come with intuitive controls, making them accessible even for those without prior experience.

Conclusion

Laser engraved tumblers are a testament to the capabilities of advanced laser engraving cutting machines. These machines not only offer precision and versatility but also enable the creation of unique, personalized products that stand the test of time. Whether you’re looking for custom drinkware or promotional items, laser engraved tumblers are an excellent choice for their durability, aesthetic appeal, and customization options.

By understanding the technical specifications and applications of both laser engraved tumblers and the machines used to create them, you can make informed decisions when selecting products that meet your needs. Whether for personal use or commercial purposes, laser engraving technology continues to revolutionize the way we personalize and customize everyday items.

If you’re interested in learning more about laser engraving or exploring its applications, consider reaching out to local engravers or checking online resources for detailed guides and tutorials. With the right tools and knowledge, you can unlock the full potential of this innovative technology!

Rosa Kuznetsov (verified owner) –

The Epilog Zing Red Dot excels in performance across wood, acrylic, and leather, offering precise cuts with consistent quality. The user experience is seamless, with an intuitive software interface that simplifies project setup. Standout features include high-speed raster engraving and air assist for clean edges. While it handles detailed projects like custom jewelry boxes effortlessly, minor adjustments are needed for intricate designs on delicate materials. Overall, its blend of power and precision makes it ideal for both artistic and business applications, providing a strong ROI with minimal learning curve.

Beatriz Vu (verified owner) –

The laser engraver excels in performance across various materials. On wood, it delivers crisp lines and deep engravings, perfect for intricate designs. Acrylic work showcases vibrant detailing due to its high-resolution settings. However, leather requires careful power adjustments to avoid burns.

Setup was straightforward, with intuitive software guiding me through configurations. The interface is user-friendly, allowing quick project uploads and adjustments.

For value, it offers excellent ROI for small businesses, especially in custom engraving services. While the initial investment is notable, long-term savings on consumables justify the cost. Minor suggestion: additional pre-loaded templates would streamline workflows.

Marco Garcia (verified owner) –

The laser engraver excels on wood, acrylic, and leather, delivering crisp details with consistent precision. On wood, intricate patterns like knotwork were rendered seamlessly, while acrylic benefited from smooth etching for professional signage. Leather projects showcased clean lines without burn marks. The 120W power setting ensures fast processing, completing a 5×5-inch design in under 3 minutes. However, the learning curve for software calibration was steep. While the interface is intuitive, advanced users may appreciate customizable settings. A minor suggestion: adding a dust management system would enhance long-term use in dusty environments. Overall, it balances performance and usability effectively.

Lucia Nguyen (verified owner) –

**Laser Engraver Experience: Product Prototyping**

In my experience with laser engravers in product prototyping, the tool has been instrumental across various projects, enhancing both efficiency and creativity.

**Specific Project Experience:**

I utilized the laser engraver for creating custom jewelry pieces, focusing on intricate designs. The machine excelled with metal and acrylic materials, producing precise engravings that were both durable and visually appealing. A challenge arose with material warping in some metals, which was mitigated by adjusting cooling settings during engraving to maintain structural integrity.

**Technical Performance:**

The laser’s power settings were easily adjustable, allowing for optimal performance on different materials. The precision achieved was remarkable, especially in fine details. The software provided user-friendly features such as vector import capabilities and layering options, enabling seamless design integration and customization.

**Business/Creative Impact:**

The laser engraver significantly accelerated production compared to manual methods, allowing us to undertake more complex projects efficiently. Customer feedback consistently highlighted the superior finish quality, enhancing satisfaction and loyalty. The tool also contributed to cost savings through reduced material waste and quicker turnaround times.

**Comparison & Value:**

Compared to traditional CNC machines or engraving tools, the laser offered higher precision and faster setup times. This reduction in post-processing needs led to significant time and resource savings. The investment in the laser engraver provided a clear ROI by improving project efficiency and output quality.

In summary, the laser engraver has proven invaluable in my prototyping workflow, offering versatility, precision, and operational efficiency that have positively impacted both productivity and client satisfaction.

Maria Martin –

“Exceptional laser engraver! Precise cuts, intuitive software, swift operation, and robust build quality make for a highly reliable, 5-star experience.”

Luigi Kim –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Luigi Williams –

“Outstanding laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and built to last. Highly recommend!”

Jennifer Chen –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost workflow. Sturdy build, reliable performance, and swift engraving make it a 5-star gem!”

Patricia Nguyen (verified owner) –

“I love these laser engraved tumblers for my coffee table—they’re a hit during gatherings! The precision in the design makes them stand out, and they feel super sturdy.”

Anders Li –

五星好评: This laser engraver delivers exceptional precision and stunning results. The software is intuitive, and operations are seamless. Fast engraving speed boosts productivity. Top-notch build quality, highly reliable!