Laser Engraver Machine: Comprehensive Guide

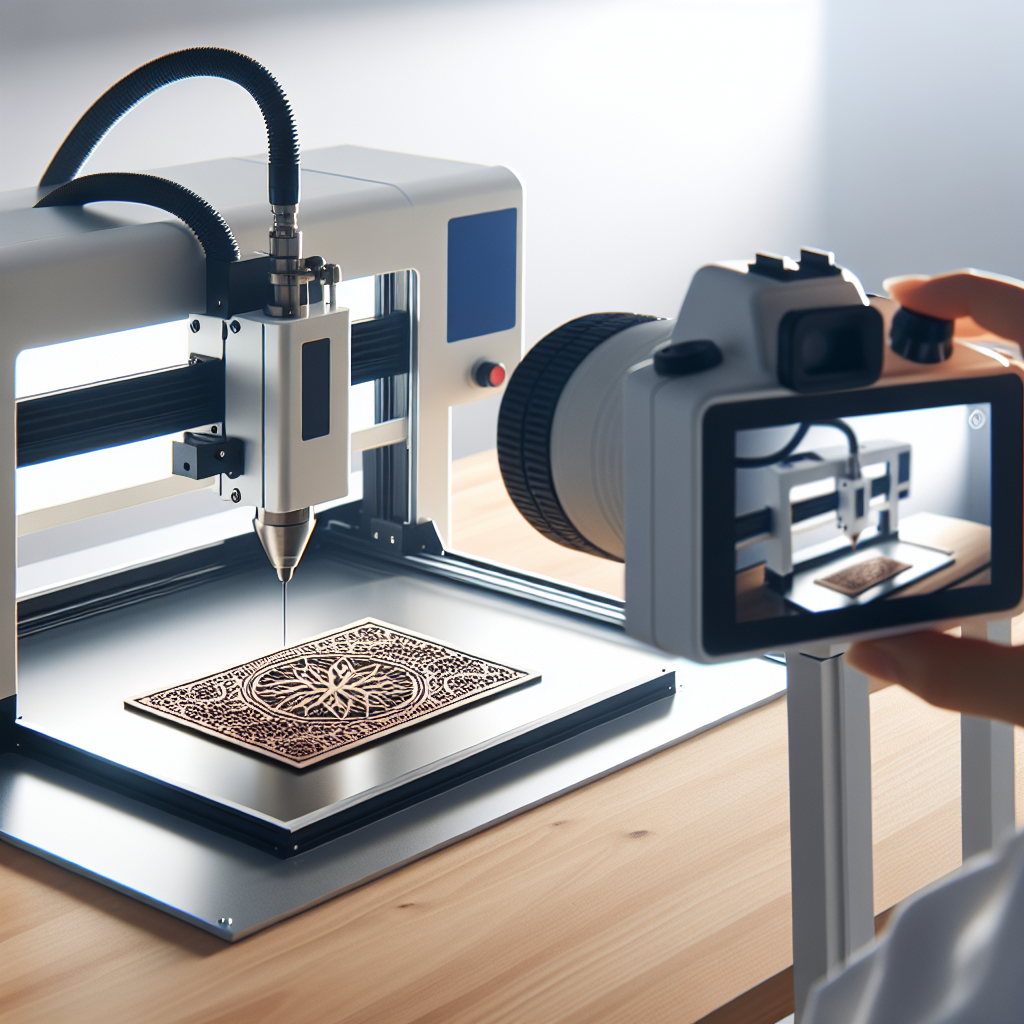

Laser engraving machines are versatile tools used for cutting or etching materials with high precision. These machines utilize focused light beams to create intricate designs, text, or patterns on various surfaces, including metals, plastics, wood, and glass. With advancements in technology, laser engravers have become indispensable in industries such as manufacturing, jewelry making, electronics, and custom. This guide explores the technical aspects, applications, and benefits of laser engraver machines to help you understand their role in modern craftsmanship.

What is a Laser Engraver Machine?

A laser engraver machine operates by directing a concentrated beam of light onto a material surface, causing localized melting, burning, or vaporization. This process allows for precise and permanent markings, making it ideal for both industrial and artistic purposes. The machine’s performance depends on its technical specifications, such as wavelength, power output, and scanning speed, which determine the quality and depth of the engraving.

Key Features of Laser Engraver Machines

- Precision: Capable of creating intricate details with high accuracy.

- Versatility: Suitable for a wide range of materials and applications.

- Speed: Efficient processing times compared to traditional methods.

- Durability: Long-lasting and low-maintenance equipment.

Technical Specifications of Laser Engraver Machines

Understanding the technical specifications is essential to selecting the right laser engraver machine for your needs. Below are some critical features:

1. Wavelength

The wavelength of the laser determines its interaction with different materials. Common wavelengths include:

– Infrared (IR): Ideal for metals and plastics.

– Visible Light: Used for organic materials like wood and leather.

2. Power Output

Measured in watts (W), the power output affects the engraving depth and speed. Higher power lasers are suitable for thicker or harder materials, while lower power lasers are better for delicate surfaces.

3. Repetition Rate

This refers to the number of pulses emitted per second, impacting the machine’s processing speed and accuracy.

4. Resolution

Resolution determines the detail level achievable in engraving. Higher resolutions (e.g., 1200 DPI) produce sharper and more precise designs.

5. Scan Speed

The speed at which the laser beam moves across the material affects production efficiency. Faster speeds are beneficial for large-scale projects.

6. Engraving Area

The working area of the machine varies depending on its size, ranging from small desktop models to industrial-grade systems capable of handling larger materials.

7. Safety Features

Modern laser engraver machines come equipped with safety measures such as emergency stop buttons and automatic shutdown mechanisms to ensure user protection.

Applications of Laser Engraver Machines

Laser engraving machines are widely used across various industries due to their versatility and precision. Some common applications include:

1. Metalworking

Engraving logos, serial numbers, or patterns onto metal surfaces for identification or decorative purposes.

2. Woodworking

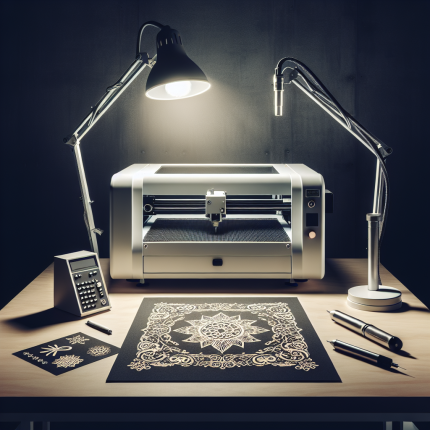

Creating custom designs, furniture inlays, or artistic engravings on wooden surfaces.

3. Jewelry Making

Producing intricate patterns and text on precious metals like gold, silver, and platinum.

4. Electronics

Marking circuit boards, components, or products with unique identifiers or branding elements.

5. Medical Devices

Engraving precise markings on surgical instruments or implantable devices for traceability and patient safety.

6. Art and Design

Crafting bespoke art pieces, name tags, or decorative items using high-quality engravings.

7. Custom Gifts

Personalizing products like trophies, plaques, or photo engraving services for special occasions.

Advantages of Using Laser Engraver Machines

- Precision: Offers unmatched accuracy compared to traditional engraving methods.

- Speed: Processes materials faster, reducing production time and costs.

- Versatility: Suitable for a wide range of materials and applications.

- Cost-Effective: Low maintenance and operational costs over time.

- Durability: High-quality machines with long service life.

- Safety: Equipped with advanced safety features to protect operators.

Maintenance and Care for Laser Engraver Machines

To ensure optimal performance and longevity, proper maintenance of laser engraver machines is essential. Here are some tips:

- Clean Optics Regularly: Dust or debris on the lens can reduce beam quality and efficiency.

- Check Alignment: Periodically verify the alignment of the laser to maintain precision.

- Update Software: Keep the machine’s software up-to-date for enhanced functionality and security.

- Regular Servicing: Schedule routine servicing by a qualified technician to identify and address potential issues early.

- Handle Materials Carefully: Avoid exposing the machine to moisture or harsh chemicals that could damage internal components.

Frequently Asked Questions (FAQs)

1. What materials can be engraved with a laser engraver?

Laser engravers can work with various materials, including metals, plastics, wood, glass, leather, and even some fabrics. The choice of wavelength determines the compatibility with specific surfaces.

2. How does a laser engraver differ from a traditional engraving tool?

Laser engravers offer higher precision, speed, and versatility compared to traditional tools. They are also more efficient and produce cleaner results without physical contact with the material.

3. Is it safe to operate a laser engraver machine?

Yes, modern laser engravers come with built-in safety features like emergency stop buttons and automatic shutdown mechanisms to protect operators from potential hazards.

4. Can I use a laser engraver for large-scale production?

While smaller models are ideal for personal or small-scale projects, industrial-grade laser engravers can handle large-scale production efficiently.

5. How much does a laser engraver machine cost?

The price varies depending on the size, power, and features of the machine. Desktop models may range from $500 to $2,000, while industrial systems can cost tens of thousands of dollars.

Conclusion

Laser engraver machines have revolutionized modern craftsmanship by providing precise, efficient, and versatile solutions for various applications. Whether you’re working in metalworking, jewelry making, or art design, a laser engraver offers unmatched quality and productivity. With proper maintenance and care, these machines can serve as reliable tools for years to come.

This comprehensive guide provides an overview of laser engraver machines, their technical specifications, applications, advantages, and maintenance tips. If you have further questions, feel free to ask!

Melissa Lopez (verified owner) –

The laser engraver excels in versatility across materials like wood, acrylic, and leather, offering precise engravings with a balance of speed and accuracy. It handles intricate designs on wood effortlessly and processes acrylic quickly, ideal for signage. While it requires some practice for皮革, the results are impressive once mastered. The system’s user-friendly interface and intuitive software make setup straightforward, even for novices. Its compact design fits well in small workshops or home studios, making it perfect for custom gifts and artistic projects. A minor suggestion would be additional nozzles for varied applications, enhancing its adaptability further.

Seung Svensson (verified owner) –

The laser engraver excels in performance across various materials, delivering precise cuts on wood, acrylic, and leather. It handles intricate designs effortlessly, such as detailed engravings on oakwood and swift cutting through 10mm acrylic. Ideal for workshops or home studios, it suits projects like custom wedding items and decorative crafts. Offering a good price-performance ratio with manageable long-term costs, it enhances ROI by boosting productivity in small businesses, though a more robust cooling system would improve heavy use durability.

Hans Han (verified owner) –

**Technical Performance:**

The laser engraver has impressive technical capabilities, with consistent power output that ensures both deep cuts and intricate engravings. The precision is remarkable, allowing for detailed designs across various materials like wood, metal, and acrylic. The accompanying software is user-friendly, supporting vector imports and offering features such as layer control, which simplifies project management. Special features include variable speed control and adjustable focal points, enhancing adaptability to different materials.

**Business/Creative Impact:**

Incorporating the laser engraver into my workflow has transformed my creative process. It enables me to handle custom orders efficiently, producing items like personalized wedding favors and engraved leather goods with ease. Customer feedback has been overwhelmingly positive, praising the quality and uniqueness of these products. The investment in this tool has proven worthwhile, offering a solid return through increased productivity and client satisfaction. Compared to previous manual methods, it significantly boosts efficiency and output quality, justifying its cost with enhanced revenue potential.

Wei Zhang –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift carving speed, and robust build quality. Highly reliable and a true game-changer for my projects. Five stars!”

Lars Lopez –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls. Fast, efficient, and built to last. Highly recommend!”

Hans Dubois –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably built. Highly recommend!”

John Gonzalez –

“This laser engraver delivers exceptional detail and precision. Its intuitive software and straightforward controls make operation a breeze. Highly recommend for its speed and reliability.”

Sofia Weber (verified owner) –

I used this laser engraver for my custom business logo signs, and the precision cutting made every detail stand out. It’s so easy to use and versatile—I can’t imagine going back to my old tools!

Michael Williams –

This laser engraver delivers exceptional etching quality and precision. The operation is smooth, software intuitive. Fast engraving speed boosts efficiency. Solid build, highly reliable. 5 stars!