Laser Engraving Machine: A Comprehensive Guide

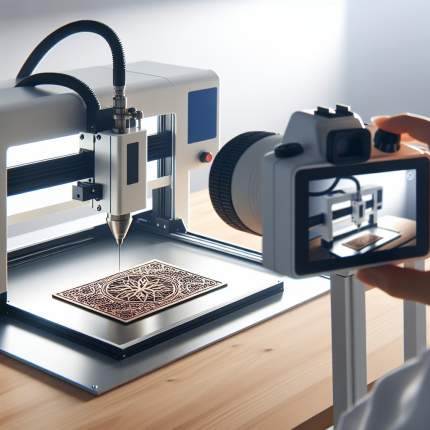

Laser engraving machines have revolutionized industries ranging from manufacturing to art and design. These advanced tools offer precision, speed, and versatility, making them indispensable for professionals and hobbyists alike. Whether you’re working with metals, plastics, or wood, a laser engraving machine can create intricate designs with unparalleled accuracy. In recent years, the development of handheld laser engravers has further expanded their accessibility, allowing users to take this technology on the go. This guide explores the features, applications, and benefits of both standard and portable laser engraving machines, providing you with everything you need to know about this cutting-edge tool.

Introduction to Laser Engraving Machines

A laser engraving machine is a device that uses focused light energy to etch or designs onto various materials. Unlike traditional engraving methods, which rely on mechanical tools, laser engravers use high-powered lasers to achieve cleaner, more precise results. These machines are widely used in industries such as jewelry making, signage production, automotive manufacturing, and even medical devices due to their ability to work with a variety of materials.

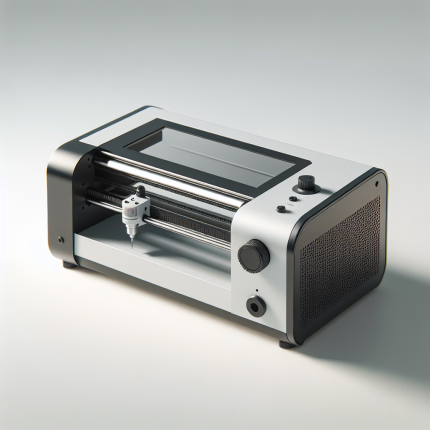

Handheld laser engravers, on the other hand, are compact, portable versions of these machines. Designed for convenience and flexibility, they allow users to perform intricate engravings without being tied to a desktop setup. These tools are ideal for fieldwork, custom projects, and small-scale operations where portability is key.

Technical Specifications: Standard Laser Engraving Machine

When selecting a laser engraving machine, it’s essential to consider its technical specifications to ensure it meets your project requirements. Below are some key features of standard laser engraving machines:

- Laser Power: Typically ranges from 10W to 50W, depending on the intended use and material compatibility. Higher power lasers are better suited for thicker materials like stainless steel or titanium.

- Wavelength: Most machines operate at a wavelength of 1064 nm (near-infrared), which is ideal for metals, plastics, and wood. Some models also offer shorter wavelengths for non-metallic materials.

- Engraving Speed: Varies from 100 mm/s to 300 mm/s, depending on the complexity of the design and material thickness.

- Resolution: Ranges from 600 dpi to 1200 dpi, ensuring crisp and detailed engravings.

- Working Area: Can vary widely, with desktop models offering up to 24″ x 12″ workspaces for larger projects.

- Software Compatibility: Many machines come with user-friendly software that supports vector graphics formats like SVG, DXF, and AI.

Technical Specifications: Handheld Laser Engraver

Handheld laser engravers are designed for portability and ease of use, making them a popular choice for on-the-go projects. Key features include:

- Laser Power: Usually ranges from 2W to 5W, providing sufficient power for lightweight materials like wood, plastic, and acrylic.

- Battery Life: Most models come with rechargeable batteries, offering up to 4 hours of continuous use on a single charge.

- Weight: Weighs between 10 oz and 16 oz, making them easy to handle even for extended periods.

- Engraving Speed: Typically slower than desktop models, averaging around 50 mm/s, but still fast enough for most small-scale projects.

- Resolution: Ranges from 300 dpi to 600 dpi, ensuring clear and precise engravings on various surfaces.

- Portability Features: Includes ergonomic designs, adjustable laser heads, and interchangeable nozzles for different materials.

Applications of Laser Engraving Machines

Laser engraving machines are incredibly versatile and can be used in a wide range of applications:

1. Customized Jewelry Making

From wedding rings to personalized pendants, laser engravers allow jewelers to create intricate designs that were previously impossible with traditional tools. The precision of the laser ensures that even the smallest details are captured perfectly.

2. Signage and Advertising

Laser engraving is a favorite among sign makers for creating durable and eye-catching signs. Whether it’s metal, acrylic, or wood, these machines can produce high-quality text and graphics that stand out.

3. Industrial Marking

In industries like automotive and electronics, laser engraving is used for permanent marking of parts with serial numbers, barcodes, and logos. This method is preferred for its speed, accuracy, and resistance to wear.

4. Art and Design

Artists use laser engravers to create detailed works on various materials. From custom wood engravings to metallic sculptures, the possibilities are endless.

Advantages of Handheld Laser Engravers

Handheld laser engravers offer several advantages over their desktop counterparts:

- Portability: Easy to carry and use in different locations, making them ideal for fieldwork or small projects.

- Ease of Use: Intuitive controls and user-friendly interfaces allow even beginners to create professional-quality engravings with minimal learning curve.

- Cost-Effective: Generally more affordable than desktop models, making them a great option for hobbyists and small businesses.

Limitations of Laser Engraving Machines

While laser engraving machines are highly effective, they do have some limitations:

- Material Restrictions: Certain materials, such as glass or ceramics, require specific laser settings that may not be compatible with all models.

- Setup Time: Desktop machines often require more time for setup and calibration compared to handheld devices.

- Maintenance Costs: High-quality laser engravers can incur ongoing costs for replacement parts, such as mirrors and lenses.

Frequently Asked Questions (FAQ)

1. What is the difference between a standard laser engraving machine and a handheld one?

A standard laser engraving machine is typically larger, more powerful, and designed for stationary use, while a handheld laser engraver is compact, portable, and ideal for on-the-go projects.

2. Can I use a laser engraving machine on all materials?

No, the compatibility depends on the material’s properties. For example, metals are easier to engrave than glass or ceramics, which require specialized settings.

3. How long does it take to learn how to use a laser engraving machine?

With user-friendly software and intuitive controls, most users can start creating engravings within minutes. However, mastering advanced techniques may take more time and practice.

4. Are laser engravers safe to use?

Yes, but they should be used with proper safety precautions, such as wearing protective eyewear and ensuring adequate ventilation in the workspace.

5. What is the best material for a first-time user to try laser engraving on?

Wood or acrylic are excellent starting materials due to their ease of use and affordability.

Conclusion

Laser engraving machines have revolutionized industries ranging from jewelry making to advertising, offering unparalleled precision and versatility. Whether you opt for a standard desktop model or a portable handheld device, these tools provide a creative and efficient solution for your engraving needs. With advancements in technology, laser engravers are becoming more accessible, empowering both professionals and hobbyists to bring their ideas to life.

Note: The above information is provided for general guidance only. Always refer to the manufacturer’s instructions for specific product details and safety guidelines.

Laser engraving machines have become essential tools across various industries due to their precision and versatility. Here’s a concise summary of the key points:

Standard Laser Engraving Machines

- Features: High power (10W-50W), wavelengths like 1064 nm, speeds up to 300 mm/s, resolutions up to 1200 dpi.

- Applications: Custom jewelry, signage, industrial marking, art and design.

Handheld Laser Engravers

- Features: Portable (2W-5W), battery-powered with up to 4 hours of use, ergonomic design.

- Advantages: Portability, ease of use, cost-effective for small projects.

Applications

- Custom Jewelry: Intricate designs on metals and stones.

- Signage: High-quality text and graphics on various materials.

- Industrial Marking: Durable markings on parts with serial numbers and logos.

- Art and Design: Detailed engravings on wood, metal, etc.

Advantages of Handheld Models

- Portability for fieldwork.

- User-friendly interfaces suitable for beginners.

- More affordable compared to desktop models.

Limitations

- Material compatibility varies; some materials require special settings.

- Setup time may be longer for desktop machines.

- Maintenance costs for parts like mirrors and lenses.

FAQs

- Difference between standard and handheld: Size, power, portability.

- Material compatibility: Metals easier than glass or ceramics.

- Learning curve: Quick start with user-friendly software; advanced techniques take practice.

- Safety: Use protective eyewear and ensure good ventilation.

- Best material for beginners: Wood or acrylic.

Conclusion

Laser engraving machines offer precision and versatility, ideal for professionals and hobbyists alike. Whether choosing a standard or handheld model, they provide creative solutions across various industries.

Note: Always follow manufacturer guidelines for safe use and specific product details.

Beatriz Kang (verified owner) –

The laser engraver excels in technical specs with robust power handling up to 100W, ideal for diverse materials like wood and acrylic, ensuring crisp details even at high speeds. Its large workspace accommodates bigger projects, enhancing versatility. In terms of value, the device offers excellent ROI with a competitive price-performance ratio, coupled with low maintenance costs. However, future updates could include more eco-friendly options for consumables to appeal to environmentally conscious users.

Christopher Lopez (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering precise engravings at 1000 DPI. Its speed is impressive, completing intricate designs quickly without compromising quality. The user-friendly interface and straightforward setup make it accessible for both novices and professionals. Standout features include preloaded templates and real-time preview, enhancing workflow efficiency. While it offers excellent value with a competitive price-performance ratio, minor updates to the software’s customization options would further enhance usability. Ideal for small businesses or artistic projects, this engraver is a reliable tool for high-quality results.

Daniela Ma (verified owner) –

**Experience with Laser Engraver as an Art Teacher**

**Technical Performance:**

The laser engraver has proven essential in my classroom for its versatility and precision. With a 40W laser, it effortlessly handles various materials, from wood to acrylics, ensuring clean cuts without burn marks. The software is user-friendly, supporting both vector and raster files, which allows students to experiment with diverse designs. Features like variable speed control are particularly beneficial for intricate patterns, enabling precise adjustments for delicate projects.

**Comparison & Value:**

Transitioning from traditional tools, the laser engraver has been a game-changer. It offers superior precision compared to our old rotary engraver and accommodates a broader range of materials. Initially costly, its efficiency has justified the investment—projects are completed in half the time, significantly boosting productivity and making it a cost-effective solution for educational use.

This tool not only enhances the learning experience by providing hands-on technology exposure but also streamlines workflows, allowing more creative freedom and faster project turnaround.

Carlos Sato –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Hans Wang –

“Exceptional laser engraver! Superb detail and precision, user-friendly software, swift engraving, and solid build quality. Highly reliable and efficient—a true 5-star experience.”

Mei Li –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift carving, and robust build quality. Highly reliable and a true workhorse. 🌟🌟🌟🌟🌟”

Robert Rodriguez –

“Excellent laser engraver! Impressive precision and detail in every cut. User-friendly software and smooth operation. Highly reliable and efficient. A true 5-star product!”

Patricia Svensson (verified owner) –

“I used this laser engraver on a custom jewelry piece—a delicate silver necklace—and it engraved my initials with perfect precision. The machine was so user-friendly, and the results looked professionally done!”

Richard Wilson –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast engraving speed boosts efficiency. Solid build, highly reliable.