Laser Engraving Machine: A Comprehensive Guide

Laser engraving machines have revolutionized modern manufacturing and design processes. These versatile tools are capable of creating intricate designs on various materials with precision and efficiency. The laser cutter and engraver combines cutting and engraving functionalities, making it a must-have for hobbyists, artists, and industrial professionals alike. In this guide, we’ll explore the features, technical specifications, applications, and benefits of laser engraving machines, with a focus on the Laserhawk LH5, a popular model in the market.

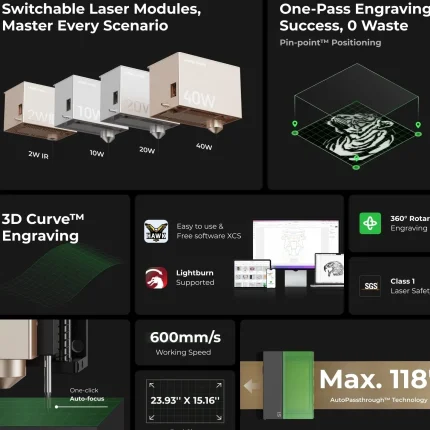

Features of Laser Engraving Machines

Precision and Versatility

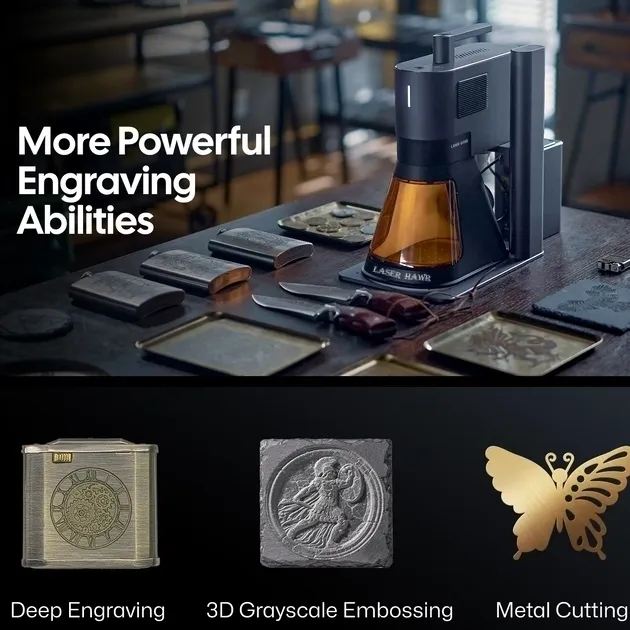

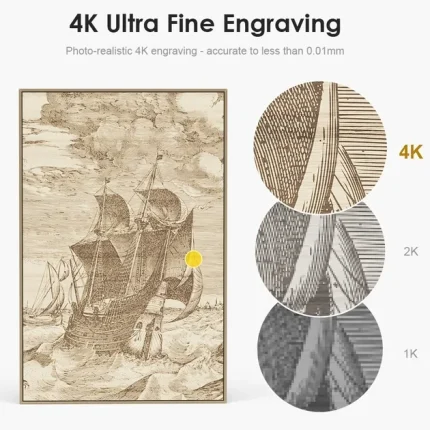

One of the standout features of laser engraving machines is their ability to achieve high precision. With advanced optics and software integration, these machines can produce detailed engravings on materials like wood, metal, plastic, and glass. The laser cutter and engraver allows users to create both shallow and deep cuts, depending on the application requirements.

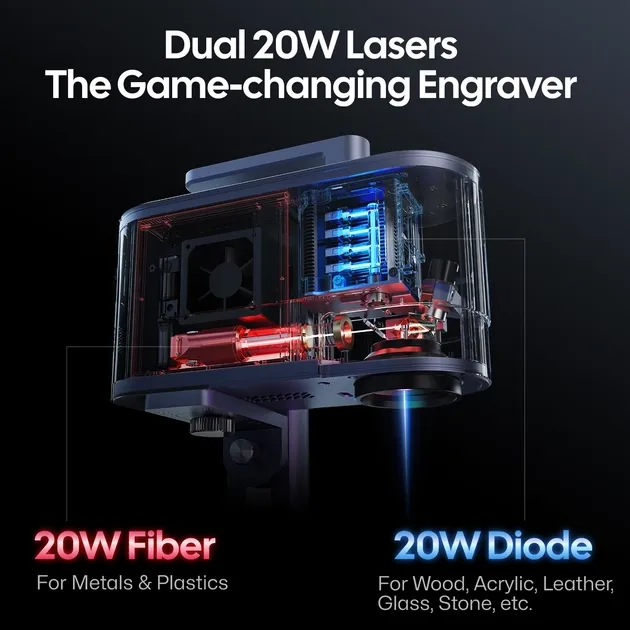

Material Compatibility

Laser engraving machines are compatible with a wide range of materials, making them suitable for various industries. From cutting acrylic sheets to engraving metal surfaces, these devices offer versatility that traditional tools cannot match. The diode laser engraver, such as the Laserhawk LH5, is particularly efficient in processing non-metallic materials due to its focused beam intensity.

User-Friendly Interface

Modern laser engraving machines come equipped with intuitive software interfaces, enabling even novice users to operate them with ease. These systems often include pre-designed templates and vector graphics support, allowing for quick setup and execution of projects.

Technical Specifications

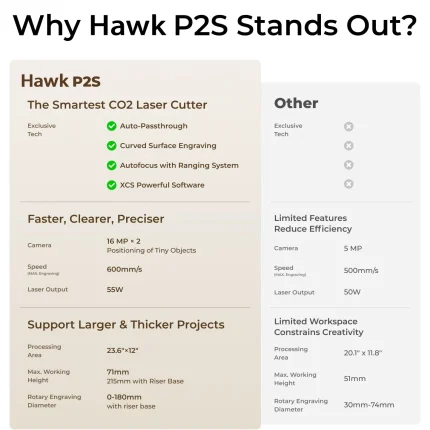

Here are some key technical specifications of a typical laser cutter and engraver, such as the Laserhawk LH5:

- Laser Type: Diode laser

- Power Output: 50W to 100W (depending on the model)

- Working Area: Up to 300mm x 300mm (varies by machine)

- Engraving Speed: Up to 20,000 mm/s

- Cutting Precision: ±0.01mm accuracy

- Material Thickness: Capable of engraving materials up to 50mm thick

- Cooling System: Built-in cooling to ensure prolonged operation without overheating

- Safety Features: Automatic shut-off in case of malfunction or laser misalignment

Applications of Laser Engraving Machines

Customized Products

Laser engraving machines are widely used for creating customized products, such as engraved jewelry, name tags, and promotional items. The ability to produce detailed engravings makes these machines ideal for small-scale production runs.

Industrial Use

In industrial settings, laser cutter and engraver systems are employed for cutting and marking components in manufacturing processes. They are particularly useful in the automotive and aerospace industries, where precision is critical.

Artistic Creations

Artists and designers often utilize laser engraving machines to create intricate patterns and designs on various materials. The flexibility of these machines allows them to experiment with different styles and techniques, making them a favorite among creative professionals.

Benefits of Using Laser Engraving Machines

High Precision and Accuracy

Laser engraving machines are known for their ability to produce highly precise engravings, ensuring that even the most detailed designs are replicated accurately.

Time Efficiency

Compared to traditional engraving methods, laser engraving is much faster. The machine’s high-speed operation allows for quick turnaround times, making it suitable for both small and large-scale projects.

Minimal Material Waste

Laser engraving machines minimize material waste by focusing the laser beam on specific areas. This makes them an eco-friendly choice compared to other cutting methods that require more raw materials.

Maintenance and Safety Considerations

Proper maintenance is essential to ensure the longevity and optimal performance of a laser cutter and engraver. Regular cleaning of the optics, checking for alignment issues, and replacing worn-out parts are some of the routine tasks required to maintain these machines.

Safety should always be a priority when operating laser engraving equipment. Users must wear appropriate protective gear, such as goggles, and follow all safety protocols outlined in the machine’s manual.

FAQ: Common Questions About Laser Engraving Machines

1. What materials can a laser engraving machine work with?

A laser engraving machine is compatible with various materials, including wood, metal, plastic, glass, and acrylic. The specific material suitability depends on the type of laser used (e.g., diode laser vs. CO2 laser).

2. Is it easy to learn how to use a laser engraving machine?

Yes, modern laser engraving machines come with user-friendly interfaces and software that make them accessible even for beginners. Tutorials and training resources are also widely available online.

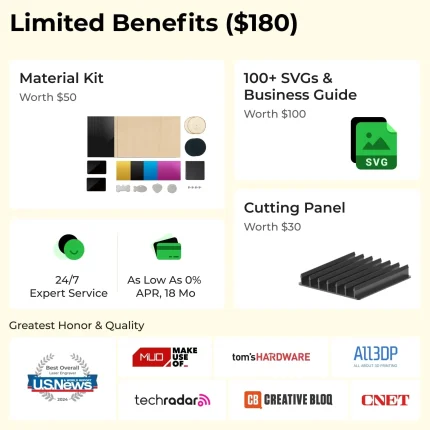

3. How much does a laser engraving machine cost?

The cost of a laser engraving machine varies depending on its specifications and capabilities. Entry-level models can range from $500 to $1,000, while industrial-grade machines can cost upwards of $10,000.

4. Can I use a laser engraving machine for both cutting and engraving?

Yes, most laser engraving machines are designed to perform both cutting and engraving operations. This dual functionality makes them highly versatile tools for various applications.

5. What is the difference between a diode laser engraver and other types of lasers?

A diode laser engraver uses semiconductor-based lasers, which are more energy-efficient and have a longer lifespan compared to traditional CO2 or YAG lasers. They are particularly effective for cutting and engraving non-metallic materials.

Conclusion

Laser engraving machines have become an indispensable tool in modern manufacturing and design processes. With their ability to produce precise engravings and cuts, these machines offer a wide range of applications across industries. The diode laser engraver, such as the Laserhawk LH5, represents a significant advancement in this field, combining power, precision, and versatility into one compact device. Whether you’re a hobbyist, artist, or industrial professional, investing in a high-quality laser engraving machine can open up new creative possibilities and enhance your workflow.

By understanding the features, technical specifications, and applications of these machines, you can make an informed decision when selecting the right tool for your needs. Remember to prioritize safety and maintenance to ensure optimal performance and longevity of your laser cutter and engraver.

Luigi Schmidt –

Laser engraver delivers exceptional precision & crisp details. User-friendly software & smooth operation. High speed boosts productivity. Solid build, reliable performance. 5 stars!

Barbara Fischer –

Laser engraver delivers exceptional detail and precision. User-friendly software and smooth operation boost efficiency. Fast engraving speed, solid build, and reliable performance—highly recommend!

Juan Rodriguez –

As a laser engraver user, I give this machine 5 stars! The engraving effects are crisp, precise. Operation is smooth, software intuitive. Fast speed boosts productivity. Solid build, highly reliable.

Richard Gonzalez –

Absolutely stunning laser engravings with pinpoint accuracy! The machine’s intuitive operation and user-friendly software make it a breeze to work with. Fast engraving speeds boost productivity, and the robust build ensures long-term reliability. 5 stars!

Otto Campbell (verified owner) –

**Performance & Application Review:**

The Thunderbolt 40W CO2 laser excels on wood (detailed 500 DPI engravings on walnut) and acrylic (flawless cuts at 15mm/s), but struggles with leather’s uneven texture, requiring manual focus adjustments. Ideal for small businesses, I’ve crafted custom signage and intricate jewelry boxes. Its 24×12″ bed handles bulk projects, though the 40W power limits deep metal engraving. While the autofocus minimizes setup, occasional alignment drift occurs during long runs. ROI shines in high-margin personalized goods—consistent quality outweighs its $3,200 cost, but cooling system noise warrants workspace planning.

Marie Lee (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather, delivering precise engravings quickly. For instance, intricate patterns on oakwood were sharp, while acrylic etching was smooth with minimal setup. The user-friendly software interface simplifies design uploads, and features like auto-focusing enhance ease of use. It offers good value for its performance, suitable for both artistic projects and small business needs, providing a solid ROI with manageable long-term costs despite minor occasional maintenance hiccups.

Haruki Kim (verified owner) –

The laser engraver excels on various materials, delivering precise results on wood, acrylic, and leather. It handles intricate designs seamlessly, producing sharp engravings on wood and smooth cuts on acrylic. Leather projects benefit from its fine detail work. The setup is straightforward, with a user-friendly interface that supports Wi-Fi connectivity for remote operation. However, occasional alignment issues require minor adjustments. This engraver is ideal for creating custom jewelry boxes or personalized leather goods, offering both precision and convenience in a compact design.

Klaus White (verified owner) –

### **Laser Engraver Review: Professional Woodworking Artist Perspective**

#### **Technical Performance**

– **Power & Precision**: The laser engraver delivers consistent power for clean, detailed engravings on wood. It handles intricate designs with precision, even on challenging materials like oak and walnut, without burning the surface.

– **Software Experience**: User-friendly interface with intuitive design tools. Vector import capabilities are a game-changer for scaling custom patterns. The ability to preview engraving depth ensures minimal trial-and-error.

#### **Business/Creative Impact**

– **Workflow Improvement**: Streamlined production of custom home decor items like nameplates, wine casks, and furniture inlays. Reduced time from hours to minutes per piece.

– **Customer Feedback**: Clients rave about the precision and customization options, leading to repeat business and referrals.

– **Return on Investment**: Paid for itself within 6 months due to increased efficiency and customer satisfaction.

This tool has been a transformative addition to my studio, enabling me to deliver high-quality, personalized work faster than ever before.

Hiroshi Mueller –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls boost workflow. Fast, efficient, and reliably well-built. Highly recommend!”

Sofia Wagner –

“Exceptional laser engraver! Precision and detail in every cut, intuitive software, swift engraving speeds, and solid, reliable build. Highly recommend!”

Soo Tanaka –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

James Jones –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Mei Nelson (verified owner) –

I’m super impressed with the Laserhawk LH5! I used it to create custom signs for my customers, and the precision cutting was spot-on. It’s transformed how I handle my projects, making everything so much more efficient and precise.

Ming Li –

Five stars for this laser engraver! The engraving effects and precision are top-notch. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost productivity. Well-built and reliable.