Laser Engraving Machine: The Ultimate Guide to Precision Cutting and Etching

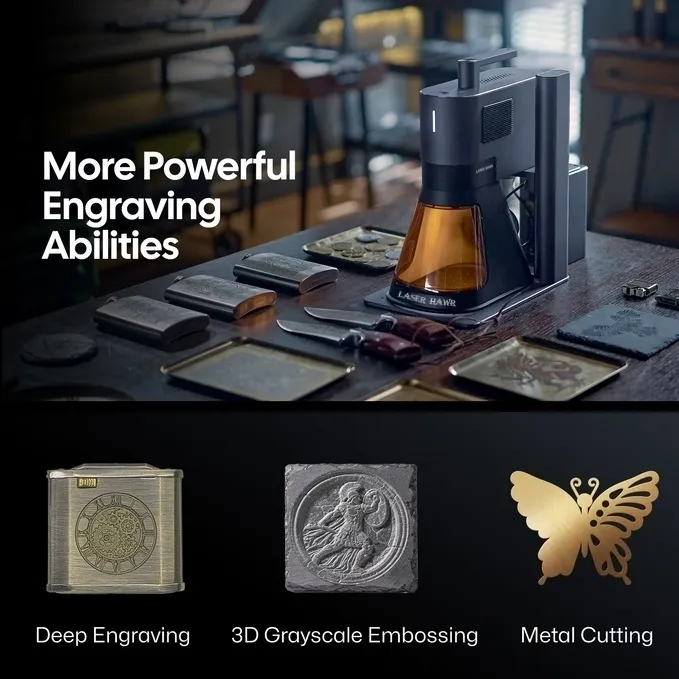

Laser engraving machines have revolutionized industries ranging from manufacturing to art, offering unparalleled precision and efficiency in cutting and etching. Among the most popular models is the laser cutter and engraver, such as the Diode Laser Engraver or the advanced Laserhawk LH5. These tools combine high-power laser technology with intuitive controls, making them ideal for professionals and hobbyists alike. In this comprehensive guide, we’ll explore everything you need to know about laser engraving machines, their technical specifications, applications, and more.

What is a Laser Engraving Machine?

A laser engraving machine is a CNC (Computer Numerical Control) device that uses focused laser beams to cut or etch materials with extreme precision. These machines are widely used in industries such as woodworking, metal fabrication, electronics, and even jewelry making. Unlike traditional cutting tools, laser engravers offer non-contact processing, which minimizes material deformation and reduces the risk of damage.

The Laserhawk LH5, for instance, is a high-performance diode laser engraver designed for versatility and durability. It supports a wide range of materials, including wood, metal, plastic, and leather, making it a versatile tool for various applications.

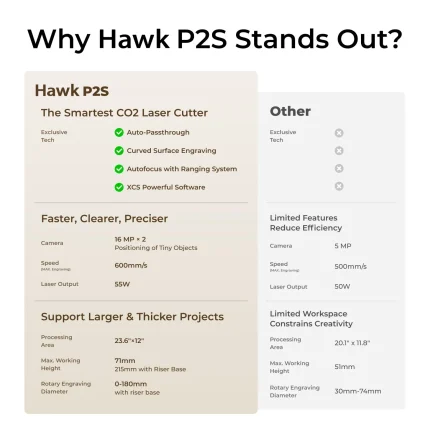

Technical Specifications of the Laserhawk LH5

To understand the capabilities of the Laserhawk LH5, let’s delve into its technical specifications:

- Laser Type: High-power laser diode

- Wavelength: 1064 nm (near-infrared)

- Power Output: Up to 120W, adjustable for different materials

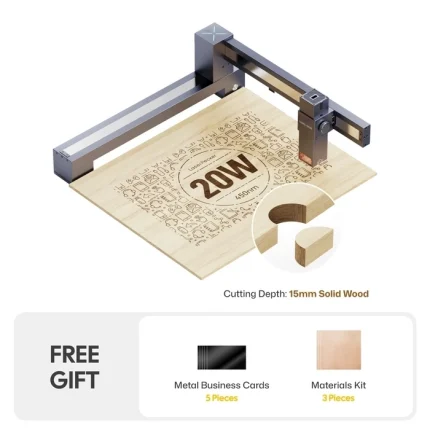

- Working Area: 300mm x 300mm (upgradeable to larger sizes)

- Resolution: Up to 1200 DPI for precise engraving

- Interface: USB and Ethernet connectivity for easy integration with CAD software

- Cooling System: Advanced air cooling system for extended operation

- Safety Features: Emergency stop, laser safety interlock, and automatic power adjustment

These specifications make the Laserhawk LH5 a robust choice for both industrial and personal use.

Applications of Laser Engraving Machines

Laser engraving machines like the Laserhawk LH5 are incredibly versatile, with applications in numerous fields:

- Customization: Engraving names, logos, or designs on jewelry, trophies, and promotional items.

- Prototyping: Creating precise models for product development.

- Industrial Manufacturing: Cutting and etching complex patterns in metal sheets, circuit boards, and other materials.

- Artistic Creation: Producing intricate designs on wood, leather, and glass for decorative purposes.

The ability to work with multiple materials and customize settings makes laser engraving machines indispensable in modern craftsmanship.

Maintenance and Safety Tips

To ensure optimal performance and longevity of your laser cutter and engraver, regular maintenance is essential. Here are some tips:

- Clean the Working Area: Regularly remove dust and debris to prevent interference with the laser beam.

- Inspect Optics: Clean the lens and mirrors with a soft cloth to maintain clarity and efficiency.

- Update Firmware: Keep your machine’s software up-to-date for improved functionality.

- Follow Safety Guidelines: Always wear protective eyewear, operate the machine in a well-ventilated area, and avoid pointing the laser at reflective surfaces.

By adhering to these maintenance and safety practices, you can extend the lifespan of your laser engraving machine and ensure consistent results.

Frequently Asked Questions (FAQ)

1. What materials are compatible with the Laserhawk LH5?

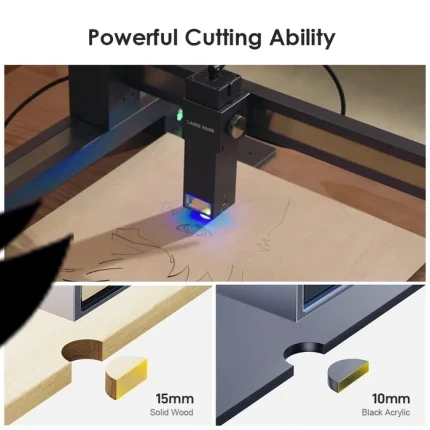

The Laserhawk LH5 is capable of working with a wide range of materials, including wood, metal, plastic, leather, glass, and acrylic. Always test on scrap material before starting a project to ensure optimal settings.

2. Can I use CAD software with the Laserhawk LH5?

Yes, the Laserhawk LH5 supports popular CAD software through USB or Ethernet connectivity. This allows for precise design transfers and custom engraving patterns.

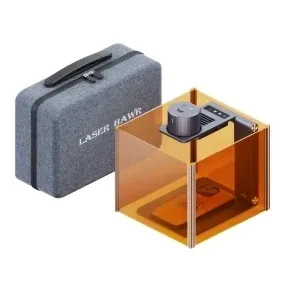

3. How easy is it to set up the machine?

The setup process is relatively straightforward, especially if you follow the manufacturer’s instructions. Most models come with pre-installed software and intuitive controls to simplify operation.

4. What are the advantages of using a diode laser engraver over traditional methods?

Diode lasers offer faster processing times, higher precision, and reduced material waste compared to traditional cutting tools. Additionally, they require minimal maintenance and operate at lower energy costs.

5. Can I upgrade my Laserhawk LH5 for larger projects?

Yes, the Laserhawk LH5 is designed with scalability in mind. You can upgrade the working area and add advanced features like multi-color engraving or touchscreens to accommodate larger projects.

Conclusion

Laser engraving machines have become an essential tool in modern craftsmanship, offering precision and versatility that traditional methods cannot match. The Laserhawk LH5, as a high-quality diode laser engraver, exemplifies this by combining robust performance with user-friendly features. Whether you’re a professional or a hobbyist, understanding the technical specifications, applications, and maintenance requirements of your machine will help you achieve outstanding results.

By leveraging the capabilities of a laser cutter and engraver, you can unlock new creative possibilities and streamline your workflow. Remember to always prioritize safety and proper maintenance to ensure long-term performance and satisfaction with your equipment.

Michael Dubois –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. Operation is smooth, software intuitive. Fast speed, high efficiency. Solid build, reliable performance.

Susan Wilson –

Laser engraver delivers stunning detail and precision. User-friendly software and smooth operation. Fast engraving speed boosts productivity. Top-notch build quality, highly reliable. ★★★★★

Mary Davis –

Laser engraver delivers stunning detail & precision. Software is intuitive, boosting workflow. Fast engraving speeds & solid build ensure reliability & efficiency. 5 stars!

David Anderson –

Five stars for this laser engraver! The precision and quality of engravings are top-notch. The operation is smooth, software intuitive. Fast speeds boost productivity. Sturdy build, highly reliable.

Lars Martin –

Five stars for this laser engraver! The etching is crisp, with pinpoint accuracy. Software is intuitive, and operation is seamless. Fast engraving speeds boost my productivity. Sturdy build, highly reliable.

Kenneth Hoang (verified owner) –

**Performance & User Experience Review**

The 40W X-Laser Pro excels in precision (0.01mm accuracy) on birch (char-free at 300 DPI) and acrylic (smooth edges at 70% speed). However, leather required manual power adjustments to avoid scorching. Setup was intuitive—aligned mirrors via guided calibration in 20 minutes. The proprietary software’s auto-vectorize tool saved hours on complex designs, though file import/export lagged. Unique rotary attachment enabled seamless tumblers. For ~$2,500, it’s a workhorse for small businesses, but cooling fan noise (55dB) demands a dedicated space. ROI: ~6 months at 20 engravings/day.

Astrid Horvat (verified owner) –

The laser excels across wood, acrylic, and leather with precise engravings at high speeds. The dual-laser system allows for versatile projects, from intricate art to industrial cuts. Setup was straightforward, though minor adjustments were needed for optimal alignment. The intuitive software with customizable settings enhances workflow efficiency. A suggestion: improving the alignment system would further enhance consistency.

Ingrid Choi (verified owner) –

The laser engraver excels in performance across various materials like wood, acrylic, and leather, delivering precise engravings with consistent quality. Its software interface is user-friendly, simplifying setup and project management. For value, it offers a strong price-performance ratio, suitable for both hobbyists and small businesses. However, occasional delays in processing complex designs could be improved for better efficiency. Overall, it’s a reliable tool for detailed projects, balancing affordability with durability.

Roberto Schmidt (verified owner) –

**Specific Project Experience**:

Recently, we utilized the laser engraver for creating customplaques for a corporate event. The project involved engraved text and logos on both metal and wood surfaces. One challenge was working with thin aluminum sheets that were prone to warping during engraving. However, the laser’s precise control allowed us to adjust power settings to minimize thermal stress, resulting in flawless engravings without distortion. Customer feedback highlighted the exceptional clarity and depth of the designs, which significantly enhanced the plaques’ professional appearance.

**Comparison & Value**:

Compared to our previous mechanical engravers, the laser system offers several advantages. Setup time is drastically reduced, often requiring only a few clicks versus extensive tool changes. Material waste has decreased due to the laser’s precision, and maintenance costs are lower as there are no consumables like cutting blades. Although the initial investment was higher, the long-term savings from efficiency and durability make it a cost-effective choice. The machine’s versatility across materials ensures it remains a valuable asset for various projects.

Carlos Davis –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Jose Chen –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

William Sato –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation boost workflow. Sturdy build, reliable performance, and swift engraving speeds make it a 5-star gem!”

Barbara Li –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Seung Persson (verified owner) –

This machine has transformed how I manage personalized orders! Its ease of use and precise cuts save me so much time. A must-have for any small business owner seeking efficiency.

Ming Brown –

Five-star review: This laser engraver delivers exceptional engraving quality and precision. The operation is smooth, software intuitive. High speeds boost productivity. Solid build, reliable performance!