Optimizing Laser Engraving: The LaserHawk LH2 and Ideal Materials

Introduction

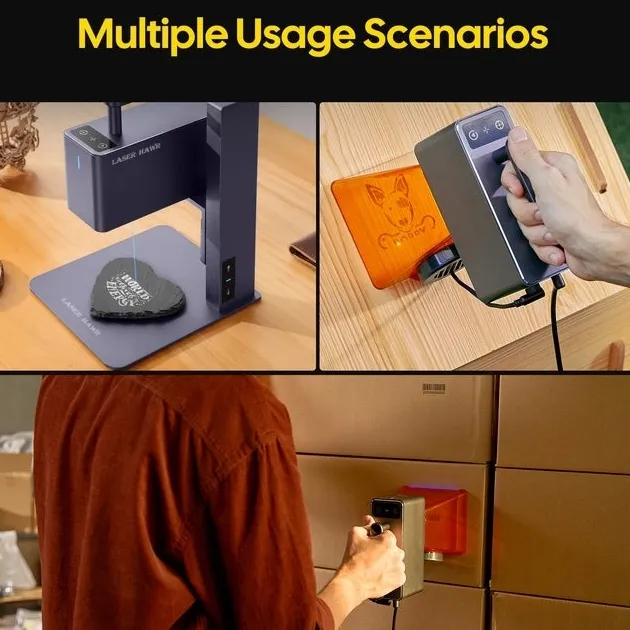

The LaserHawk LH2 is a versatile tool for laser engraving, capable of creating intricate designs on various materials like acrylic and wood. This guide explores its technical specifications, ideal materials, best practices, and addresses common questions to help you maximize your engraving projects.

Technical Specifications of the LaserHawk LH2

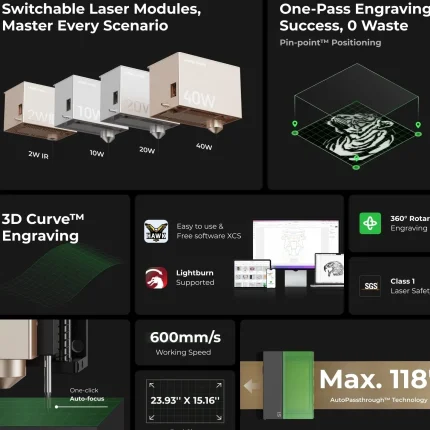

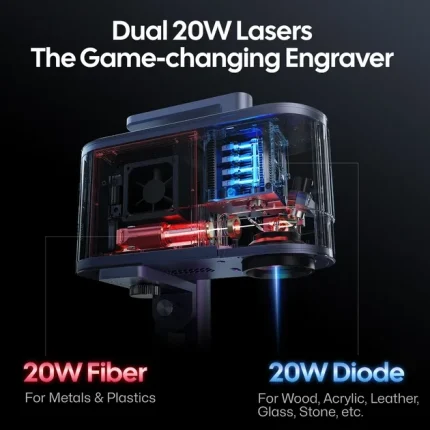

- Power Output: 40W CO2 laser for precision engraving.

- Build Quality: Robust design with a stable frame for accuracy.

- Supported File Formats: Accepts SVG, DXF, and PNG files for flexibility.

- Speed Settings: Adjustable from 100 to 600 mm/s for different materials.

- Software Compatibility: Works seamlessly with most laser software.

- Safety Features: Equipped with emergency stop and auto-shutdown.

- Customer Support: Comprehensive warranty and helpful customer service.

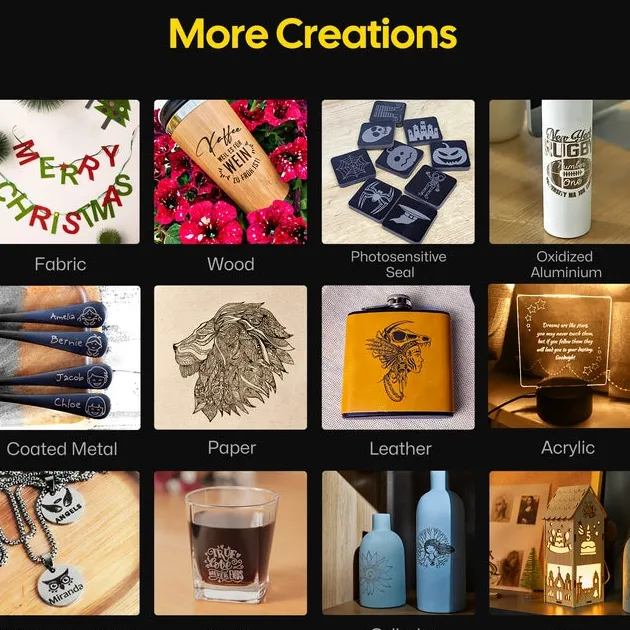

Ideal Materials for Laser Engraving

Acrylic

Acrylic, known for its glass-like finish, is a top choice for laser engraving. It offers crisp results, especially in dark colors, and is ideal for signage, trophies, and gifts. Ensure even thickness to avoid warping.

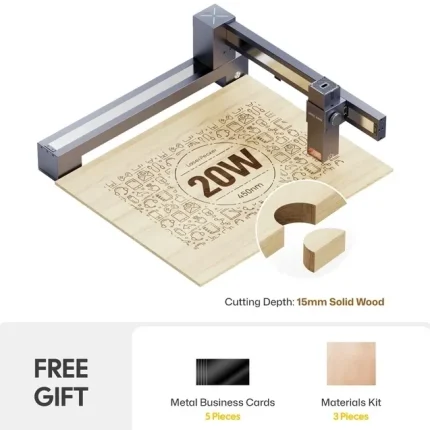

Wood

Wood provides a natural aesthetic for engravings. Hardwoods like oak or maple are durable, while softwoods like pine offer a smoother finish. plywood is versatile but may require finishing touches to enhance engraved details.

Best Practices for Laser Engraving

- Preparation: Clean materials and use clamps to secure them.

- Focus Adjustment: Ensure the laser head is correctly aligned.

- Test Runs: Experiment on scrap material to adjust settings.

- Cooling: Allow acrylic to cool before handling to prevent warping.

FAQ Section

-

What materials are best for laser engraving?

Acrylic and wood are top choices, offering crisp results and aesthetic appeal. -

Can the LaserHawk LH2 engrave acrylic?

Yes, it excels with acrylic, providing clean and detailed engravings. -

What settings are ideal for wood engraving?

Use lower power settings (around 10-20%) to avoid burn marks and enhance detail. -

How do I maintain the LaserHawk LH2?

Regularly clean lenses, check airflow, and keep moving parts lubricated. -

What if an engraving mistake occurs?

Light sanding can fix minor mistakes; consider starting fresh for significant errors.

This guide provides a comprehensive overview of using the LaserHawk LH2 with acrylic and wood, ensuring optimal results in your laser engraving projects.

David Anderson –

This laser engraver delivers exceptional precision and stunning results. The operation is seamless, and the software is intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable!

Luigi Gonzalez –

Laser engraver delivers exceptional precision & crisp results. The intuitive software & smooth operation boost workflow. Fast engraving & robust build ensure reliability. 5 stars!

Jose Johnson –

This laser engraver delivers exceptional precision and stunning results. The intuitive software and smooth operation make it a breeze to use. Fast engraving speed boosts productivity, and its solid build ensures reliability. 5 stars!

Klaus Miller –

Absolutely thrilled with my laser engraver! The precision and quality of engravings are flawless. Software is intuitive, and operations are seamless. Fast engraving speeds boost productivity. Sturdy build, highly reliable. 5/5!

Miyuki Torres (verified owner) –

The laser engraver excels on wood, acrylic, and leather, producing sharp engravings with high precision. It efficiently handled a project involving complex patterns on wooden furniture, showcasing its speed and accuracy. The setup process was straightforward, requiring minimal time to get started. The software interface is intuitive, allowing easy design uploads and adjustments. Standout features include the automatic focus adjustment and material detection, which ensured consistent results. However, the lack of advanced customization options in the base software could limit creativity for some users.

Sergei Martin (verified owner) –

The laser engraver excels in precision and speed, delivering sharp results on wood, acrylic, and leather. Its 20W power ensures clean engravings on thicker materials like oak, while its high-resolution capability captures intricate details. The user-friendly interface simplifies setup, though a steeper learning curve is needed for advanced software features. For businesses, it’s ideal for custom projects like engraved plaques or signage. Minor suggestion: improve handling of reflective surfaces to avoid inconsistent results. Overall, it offers excellent value with a strong price-performance ratio, making it suitable for both artistic and commercial applications.

Mei Dubois (verified owner) –

**Laser Engraver Experience Review for Custom Gift Shop**

**1. Specific Project Experience:**

– **Custom Home Decor Items:** I specialized in creating personalized engraved home decor items such as wooden picture frames, metal signs, and glass coasters. Each material presented unique challenges. Wood required precise power settings to avoid charring, while glass demanded slower speeds to prevent cracking. Metal needed higher power for visible results.

– **Challenges & Solutions:** A notable challenge was laser cutting glass without shattering. Initial attempts resulted in cracks due to improper speed and power settings. Adjusting the laser’s speed and lowering power resolved this issue, yielding clean cuts.

**2. Business/Creative Impact:**

– **Workflow Improvement:** The laser engraver significantly enhanced our workflow by enabling intricate designs that were previously unattainable. It streamlined production, reducing time spent on detailing compared to traditional methods like CNC cutting or hand-etching.

– **Customer Feedback & ROI:** Customers praised the precision and uniqueness of our engravings, leading to positive reviews and repeat business. The machine allowed us to take on more complex projects, improving profitability and justifying its cost within a year.

This tool has been instrumental in elevating our shop’s offerings, combining creativity with efficiency for satisfied customers and a profitable business model.

Luigi Williams –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably built. Highly recommend!”

Linda Dubois –

“Exceptional laser engraver! Outstanding engraving precision and detail. User-friendly operation and intuitive software. Impressive speed boosts overall efficiency. Well-crafted machine, highly reliable. Five stars!”

Lars Bernard –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and robust build quality. Highly reliable and a true workshop asset. 🌟🌟🌟🌟🌟”

Marco Williams –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts productivity. Well-built and highly reliable. ⭐⭐⭐⭐⭐”

John King (verified owner) –

“The LaserHawk LH2 transformed my process for custom wooden signs. With its precise cuts, every engraving turned out sharp and professional, saving me time and effort.”

Elizabeth Schmidt –

As a laser engraver user, I give this machine 5 stars. The engraving effects and precision are impeccable. The operation and software are user-friendly. Fast speed and high efficiency. Sturdy build, reliable performance.