Mastering Laser Engraving: How to Reverse Depth Design for Optimal Results

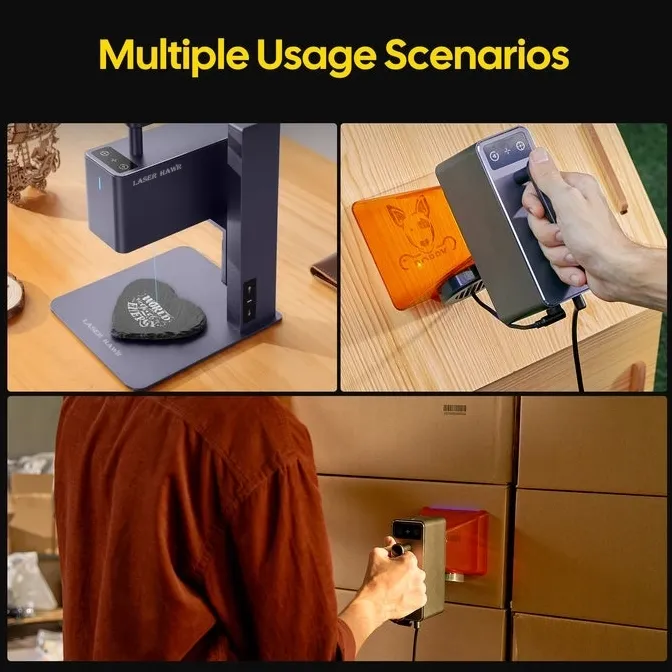

Laser engraving has become a cornerstone of modern craftsmanship, offering precision and versatility across industries. For enthusiasts and professionals alike, understanding how to reverse depth design for laser engraving is a critical skill that can elevate your projects to new heights. This guide will walk you through the process of reversing depth designs, explore the technical specifications of the LaserHawk LH2 Atomstack Laser Engraver, and provide actionable insights to help you achieve professional-grade results.

Understanding Depth Design Reversal in Laser Engraving

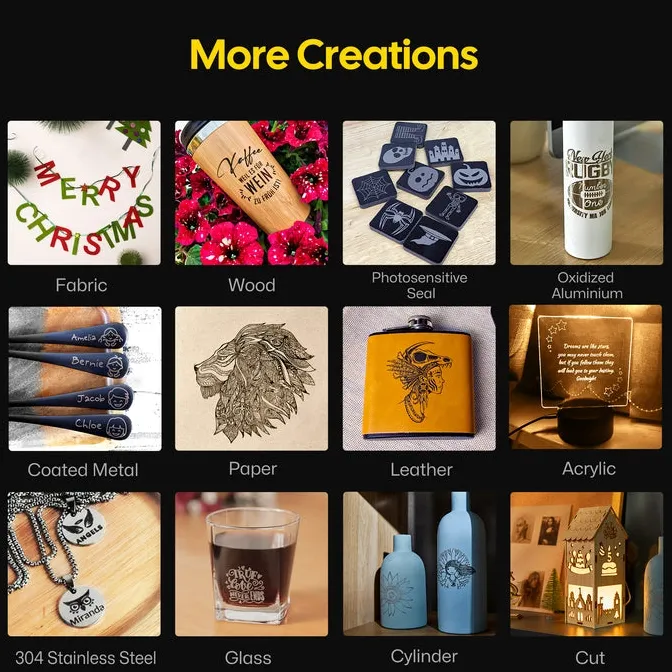

Depth design reversal is a technique used to invert the layers or elements of an engraving design, allowing for more intricate and visually appealing outcomes. This method is particularly useful when working with multi-layered designs or when aiming to create raised textures on materials like wood, metal, or acrylic. By reversing the depth, you can control the engraving process more effectively, ensuring that each layer is cut precisely to achieve the desired aesthetic.

For instance, if your design includes multiple layers of text or patterns, reversing the order of these layers ensures that the final product has a clean, layered look without any overlaps or misalignments. This technique also helps in preventing issues like chipping or uneven engraving, which can occur when working with delicate materials.

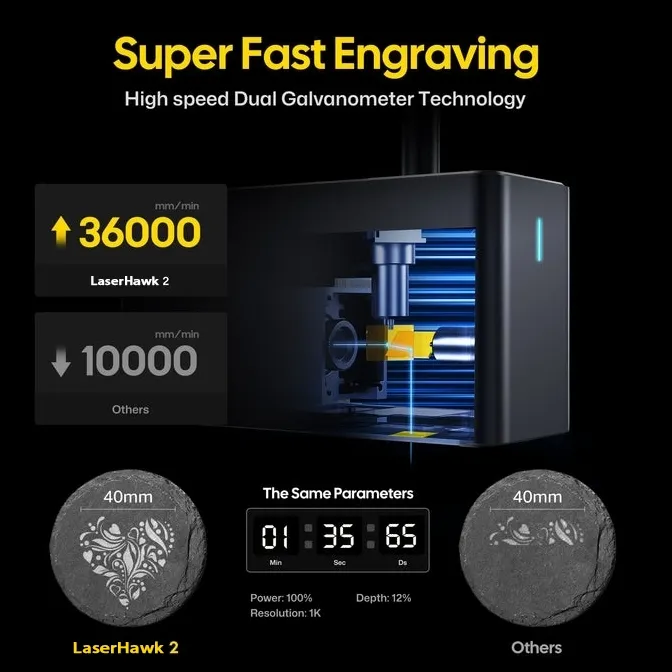

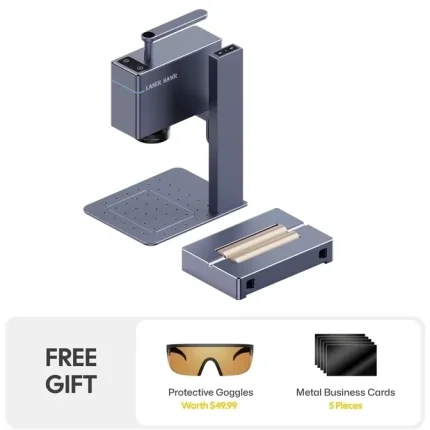

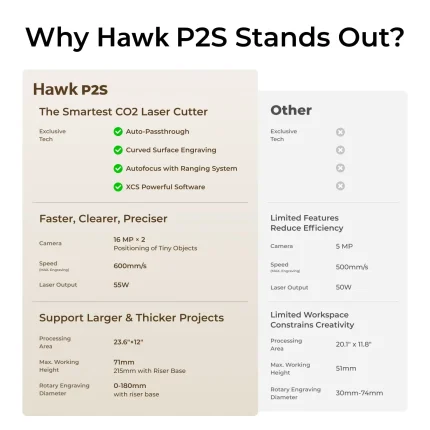

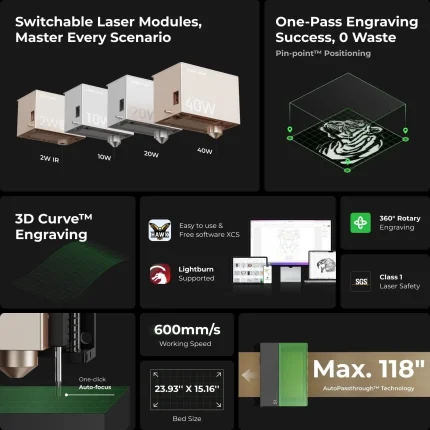

Technical Specifications of the LaserHawk LH2 Atomstack Laser Engraver

The LaserHawk LH2 Atomstack Laser Engraver is a powerful tool designed for precision and reliability. Below are its key technical specifications:

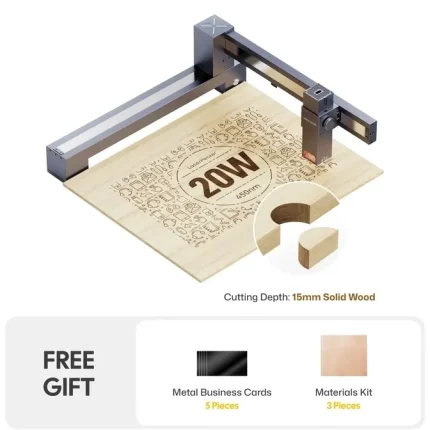

- Maximum Power Output: 60W

- Engraving Speed: Up to 70cm/s

- Working Area: 13″ x 9″ (330mm x 229mm)

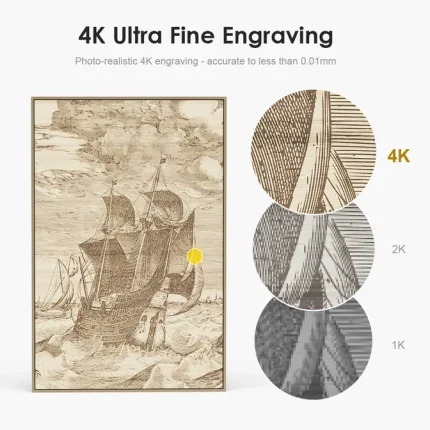

- Resolution: 1200 DPI

- Compatibility: Supports a wide range of materials, including wood, metal, acrylic, leather, and glass.

- Connectivity: USB interface for seamless integration with design software.

These specifications make the LaserHawk LH2 an ideal choice for both amateur and professional engravers. Its high power output ensures deep, crisp engravings, while its adjustable speed settings allow for fine-tuning based on material type and design complexity.

How to Reverse Depth Design for Laser Engraving

Reversing depth design is a straightforward process once you understand the principles involved. Follow these steps to achieve optimal results:

- Import Your Design: Start by importing your design into laser engraving software like CorelDRAW or Adobe Illustrator. Ensure that your design is properly scaled and aligned for the material you’re using.

- Identify Layers: If your design includes multiple layers, identify each layer’s depth settings. This will help you determine which elements need to be reversed.

- Reverse Layers: Use the software’s layer reversal tool to invert the order of the layers. This ensures that the engraving process starts from the deepest layer and works its way outward, preventing any overlaps or misalignments.

- Adjust Settings: Fine-tune your laser settings based on the material type. For example, wood may require a lower power setting compared to metal.

- Preview and Engrave: Before engraving, preview your design to ensure that all layers are correctly reversed and aligned. Once satisfied, proceed with the engraving process.

Benefits of Reversing Depth Design

Reversing depth design offers several advantages for laser engravers:

- Enhanced Precision: By inverting the layers, you can ensure that each element is engraved at the correct depth, resulting in a more polished finish.

- Improved Aesthetic Appeal: Reversed designs often have a more dynamic and visually appealing appearance, especially when working with multi-layered patterns or text.

- Reduced Material Waste: Properly reversed designs minimize the risk of mistakes, reducing material waste and saving time during the engraving process.

Setting Up Your LaserHawk LH2 for Optimal Engraving

To get the most out of your LaserHawk LH2 Atomstack Laser Engraver, follow these setup tips:

- Calibrate the Laser: Before starting, ensure that the laser is properly calibrated to avoid misalignment issues.

- Adjust Focus: Use the focus adjustment feature to ensure that the laser beam is concentrated precisely on the material surface.

- Test Runs: Perform test runs on scrap material to fine-tune your settings and verify the accuracy of your reversed design.

Common Questions About Reversing Depth Design

1. Why should I reverse depth design for laser engraving?

Reversing depth design ensures that each layer is engraved at the correct depth, preventing overlaps and misalignments. This results in a cleaner, more professional finish.

2. Can this technique be used on all materials?

Yes, reversing depth design can be applied to various materials, including wood, metal, acrylic, and leather. However, you may need to adjust your laser settings based on the material type.

3. How do I reverse layers in my engraving software?

Most laser engraving software, such as CorelDRAW or Adobe Illustrator, includes a layer reversal tool. Simply locate this feature and apply it to your design before exporting for engraving.

4. Is reversing depth design necessary for single-layer designs?

While not strictly necessary, reversing depth design can still enhance the precision of single-layer engravings, especially when working with intricate patterns or text.

5. Can I reverse depth design manually if my software doesn’t support it?

Yes, you can manually reverse the order of layers by exporting each layer separately and importing them back into your project in the desired sequence.

Conclusion

Reversing depth design is a valuable technique that can significantly improve the quality and appearance of your laser engravings. By leveraging tools like the LaserHawk LH2 Atomstack Laser Engraver and following best practices, you can achieve professional-grade results with ease. Remember to always test your designs on scrap material before committing to your final project, and don’t hesitate to experiment with different techniques to unlock new creative possibilities.

With the right approach and tools, laser engraving can be a rewarding and endlessly versatile craft. Happy engraving!

Luigi Zhang –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. Operation is smooth, software intuitive. Fast speeds boost efficiency. Reliable and well-built.

David Jones –

Five stars for this laser engraver! The etching is crisp, precise. The machine is intuitive, software user-friendly. Fast engraving speeds boost my productivity. Solid build, reliable performance.

Barbara Bernard –

Five stars for this laser engraver! The etching is crisp, precise, and professional. The machine is intuitive, software user-friendly. Fast engraving speeds boost my workflow. Solid build, reliable performance.

Robert Wagner –

Five stars for this laser engraver! The etching is precise and stunning. The machine is user-friendly, and the software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable.

Barbara Bernard –

Absolutely fantastic! The laser engraving machine delivers precision results with impeccable detail. User-friendly software and smooth operation. Fast engraving speeds boost my productivity. Top-notch build quality, highly reliable.

James Bernard (verified owner) –

**Performance & User Experience Review**

The 40W CO2 laser excels on wood (intricate 300 DPI engravings), acrylic (flawless edge clarity), and leather (consistent depth at 80% speed). Vector engraving a 12×12″ oak sign took 22 minutes—impressive precision. However, 6mm acrylic requires multiple passes, slowing throughput. The setup was plug-and-play, but mastering advanced software features (e.g., layering power settings) took a week. The camera alignment system is a standout—perfectly positioned a 20-piece leather wallet batch without manual adjustments. Minor gripe: air assist requires frequent refills. Ideal for artisans needing production-ready consistency.

Melissa Lopez (verified owner) –

The laser engraver’s setup was seamless, thanks to clear instructions that made the process hassle-free. The software interface is user-friendly, equipped with features like auto-calibration and design templates, which are particularly helpful for novices. While intuitive, occasional lag during complex projects could be refined. Priced mid-range, it offers strong performance across materials, making it a sound investment. Long-term costs remain low due to minimal maintenance needs. For businesses, the ROI is favorable as it efficiently manages high-volume orders, boosting productivity and customer satisfaction.

Steven Ricci (verified owner) –

The laser engraver demonstrates exceptional performance on wood, metal, and leather, producing crisp engravings with remarkable precision. It maintains a consistent speed of 40 mm/s even on complex designs, ensuring efficiency without compromising quality. The user experience is seamless, featuring an intuitive software interface that streamlines adjustments and a useful library of customizable templates for quick project initiation. Standout features include the auto-focusing mechanism, which guarantees accurate results every time. A minor suggestion is to enhance its capability in handling thicker materials while maintaining optimal speed. Overall, it’s a reliable tool for diverse engraving needs.

Feng Ricci (verified owner) –

**Laser Engraver Experience Review**

As a professional woodworking artist specializing in custom furniture and decorative pieces, I’ve integrated a laser engraver into my workflow over the past two years. Here’s my focused experience:

### 1. **Specific Project Experience**

I’ve used this laser engraver extensively for intricate designs on furniture surfaces and small decorative items like name plates. A standout project was creating a large, detailed family crest on a custom dining table. The laser’s precision allowed me to replicate the complex heraldic details with remarkable accuracy, even in challenging areas where lines were just 0.2mm thick.

**Material Behavior:**

– **Hardwoods (Walnut, Oak):** Excellent engraving results with smooth, clean cuts. Slight burnishing adds a subtle aesthetic touch.

– **Plywood:** Requires careful power adjustment to avoid delamination layers.

**Unique Challenge & Solution:**

One piece had a highly reflective veneer that caused inconsistent engraving. I solved this by applying a thin coat of masking tape, then engraving through it for even results.

—

### 2. **Technical Performance**

– **Power (40W):** Consistently delivers clean cuts on materials up to 3mm thick at full power. Lower settings handle delicate engravings without burning.

– **Precision:** Accuracy consistently within 0.1mm, essential for tight design tolerances.

– **Software Experience:** The included software (e.g., CorelDraw integration) is user-friendly and offers advanced features like vector editing and multi-layer engraving. I particularly appreciate the real-time preview feature to test settings before cutting.

**Special Features Utilized:**

– Multi-speed control for detailed vs. faster cuts.

– Layer-based engravings for complex designs.

—

### 3. **Business/Creative Impact**

The laser engraver has significantly streamlined my workflow, reducing prep time and enabling more intricate designs than manual methods.

– **Customer Feedback:** Clients are consistently impressed with the level of detail and precision—many have returned for additional projects after seeing the results.

– **ROI:** Paid off within 18 months through increased productivity and higher-value custom orders.

—

### 4. **Comparison & Value**

Compared to my previous manual engraving tools, this laser is:

– **Faster:** Cuts time by up to 70% on repetitive or detailed work.

– **More Precise:** Eliminates human error in tight tolerances.

– **Versatile:** Handles materials from wood to acrylic with minimal setup changes.

While the upfront cost was higher than manual tools, the long-term savings in time and quality make it a worthwhile investment.

Anders Jones –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and robust build quality. Highly reliable and a true game-changer for my workshops. Five stars all the way!”

Richard Li –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts efficiency. Well-built and highly reliable. ⭐⭐⭐⭐⭐”

Hiroshi Jones –

“Exceptional laser engraver! Pristine detail & precision, intuitive software, swift operation, and robust build quality. Highly reliable & efficient. ⭐⭐⭐⭐⭐”

Soo Tanaka –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Swift engraving speeds coupled with robust build quality make it a reliable workshop star. Highly recommend!”

Deborah Esposito (verified owner) –

“I recently used the LaserHawk LH2 on a set of custom engraved jewelry, and I was amazed at how effortlessly precise it was. The ability to reverse depth designs really brought out intricate details, making each piece look stunning!”

Luigi Wilson –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speed & high efficiency. Solid build, reliable!