Exploring Laser Engraving Projects: Creative Ideas and Tips for Laser Engraving Success

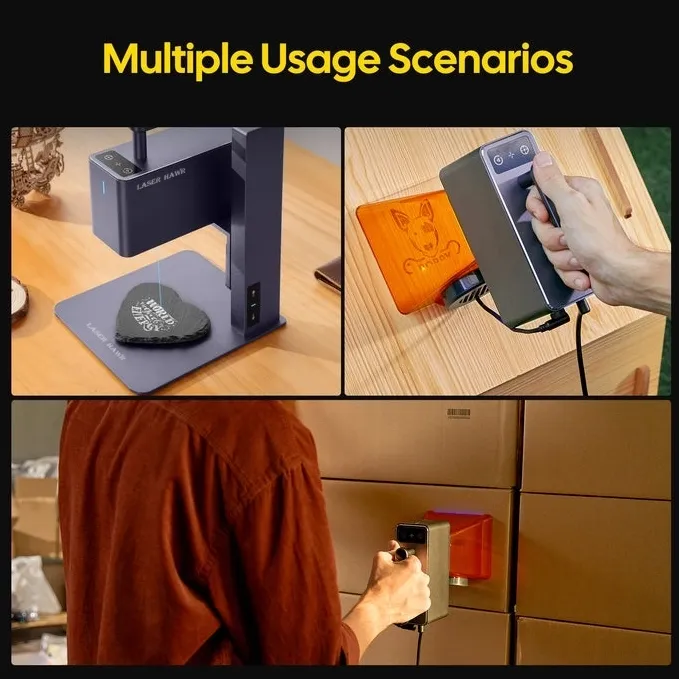

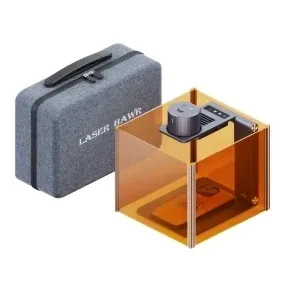

Laser engraving has become a popular technique for creating intricate designs, personalized gifts, and durable markings on various materials. With tools like the LaserHawk LH2, hobbyists and professionals alike can unlock their creativity by exploring endless laser engraving projects and innovative laser engrave ideas. Whether you’re new to laser engraving or looking for fresh inspiration, this guide will walk you through the technical aspects of laser engraving, creative project ideas, and best practices to get started.

What is Laser Engraving?

Laser engraving is a precise process that uses high-powered lasers to etch designs onto materials such as wood, metal, plastic, glass, and leather. Unlike traditional engraving methods, laser engraving offers unparalleled accuracy, speed, and versatility. The LaserHawk LH2 is a compact yet powerful machine designed for hobbyists and small-scale projects, making it an excellent choice for those looking to explore the world of laser engraving.

Getting Started with Laser Engraving Projects

Understanding the Basics

Before diving into your first laser engraving project, it’s essential to understand the basics of how a laser engraver works. The LaserHawk LH2 uses a focused laser beam to remove material from the surface, creating permanent and detailed designs. This process is ideal for both artistic and functional applications.

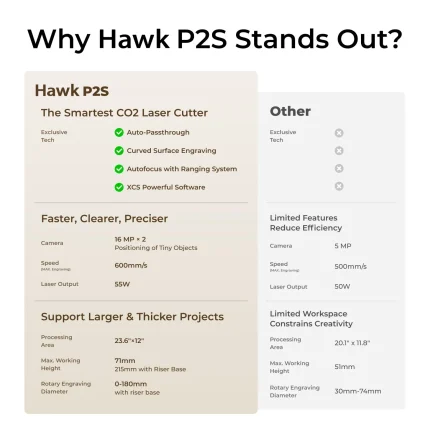

Key Features of the LaserHawk LH2

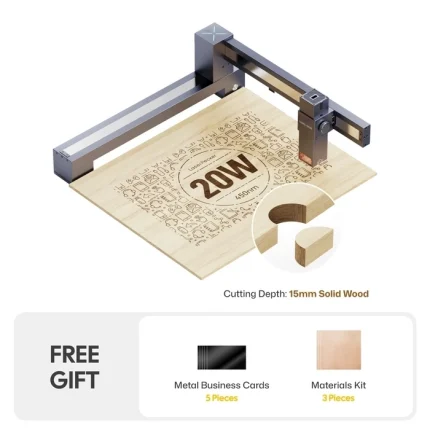

Here are some technical specifications of the LaserHawk LH2:

– Power Output: Up to 40W CO2 laser

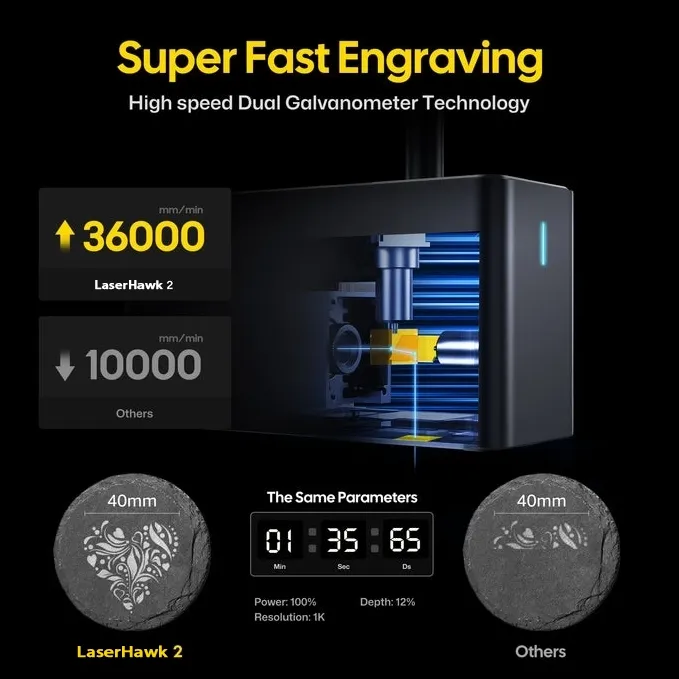

– Engraving Speed: Variable settings up to 15,000 mm/s

– Resolution: Up to 600 DPI for crisp details

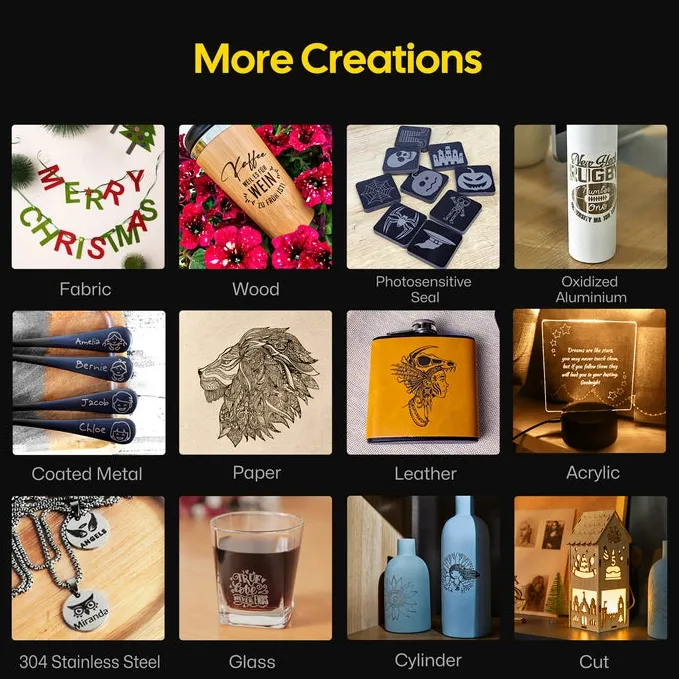

– Material Compatibility: Suitable for wood, metal, acrylic, leather, and more

– Software Integration: Works with popular design software like Adobe Illustrator and CorelDRAW

Creative Laser Engraving Ideas

Personalized Gifts

Laser engraving is perfect for creating unique and personalized gifts. Consider the following ideas:

– Custom name tags for jewelry or accessories

– Engraved wedding favors, such as custom-cut acrylic coasters or engraved metal keepsakes

– Customized pet tags with your furry friend’s details

Home Decor Projects

Transform ordinary household items into statement pieces with laser engraving:

– Create decorative wall art with intricate patterns or family crests

– Engrave personalized signs for rooms, such as “Welcome” signs or nameplates

– Design custom cutting boards with engraved designs or quotes

DIY Repairs and Customizations

Laser engraving can also be a handy tool for repairs and customizations:

– Repair scratched surfaces on furniture by engraving a new design over the damaged area

– Customize tools, guns, or other equipment with your name or a specific pattern

– Engrave detailed maps or motivational quotes onto items like phone cases or water bottles

Artistic Expression

For artists and crafters, laser engraving opens up a world of possibilities:

– Create fine art pieces by engraving detailed portraits or abstract designs on wood or metal

– Design custom puzzles with interlocking pieces engraved for unique patterns

– Engrave 3D effects on materials like leather or acrylic to add depth and dimension

Technical Tips for Laser Engraving Success

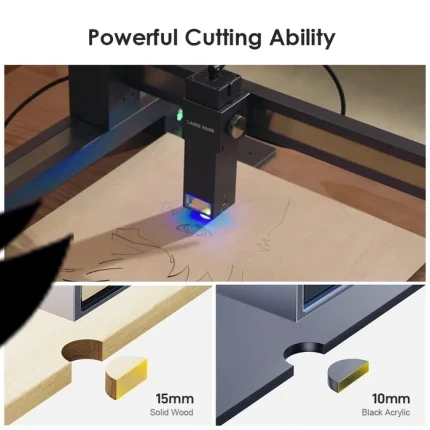

Choosing the Right Material

The success of your laser engraving project depends heavily on selecting the right material. The LaserHawk LH2 is compatible with a variety of materials, including:

– Wood (plywood, birch, oak)

– Acrylic and plastic

– Metal (steel, stainless steel, aluminum)

– Leather

– Glass

Each material has unique engraving characteristics. For example, wood tends to produce a natural, charred finish, while metal requires higher power settings for deep engravings.

Design Software Recommendations

To create your laser engraving designs, you’ll need compatible software. Popular options include:

– Adobe Illustrator: Great for vector-based designs and scalable graphics

– CorelDRAW: Ideal for creating detailed patterns and text

– Inkscape: A free, open-source alternative for vector design

Setting Up Your Laser Engraver

Before starting your project, ensure your laser engraver is properly set up:

1. Calibrate the machine according to the manufacturer’s instructions.

2. Test the laser on scrap material to adjust power and speed settings.

3. Secure your workpiece firmly in place to prevent movement during engraving.

Frequently Asked Questions (FAQ)

1. What materials can I use with the LaserHawk LH2?

The LaserHawk LH2 is compatible with a wide range of materials, including wood, metal, acrylic, leather, and glass. Always test on scrap material before starting your project to ensure optimal results.

2. How do I design laser engraving patterns?

You can use design software like Adobe Illustrator, CorelDRAW, or Inkscape to create vector-based designs for laser engraving. Ensure your designs are scalable and suitable for the material you’re using.

3. Can I engrave on glass with the LaserHawk LH2?

Yes, the LaserHawk LH2 can engrave on glass, but it requires precise power settings to avoid cracking the surface. Start with low power and gradually increase as needed.

4. What are common mistakes in laser engraving?

Common mistakes include using incorrect power settings for the material, improper focusing of the laser beam, and failing to secure the workpiece properly. Always test on scrap material first.

5. How can I clean up my laser engravings?

After engraving, use a soft cloth or brush to remove any debris from the engraved area. For metal surfaces, consider using steel wool or fine-grit sandpaper to smooth out rough edges.

Conclusion

Laser engraving is a versatile and rewarding craft that allows you to create custom designs for gifts, home decor, repairs, and artistic expression. With tools like the LaserHawk LH2, even beginners can explore creative laser engraving projects and bring their ideas to life. By understanding the technical specifications of your laser engraver, selecting the right materials, and experimenting with different design techniques, you’ll be able to achieve stunning results in no time. So why not start brainstorming your next laser engrave idea today?

For more resources on laser engraving projects and tips, check out our guide on mastering laser engraving or explore our collection of custom design templates. Happy creating!

Maria Anderson –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are impeccable. The operation and software are user-friendly. Fast speed, high efficiency, solid build, reliable!

Susan Dubois –

As a laser engraver user, I give this machine 5 stars. The engraving is precise & stunning. The software is intuitive, and the machine runs smoothly. Fast speeds boost my productivity. Sturdy build, highly reliable!

Young Jones –

Laser engraver delivers stunning results with exceptional precision. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Sturdy build, highly reliable. 5 stars!

Anders Lopez –

As a laser engraver user, I give this machine 5 stars. The engravings are precise and stunning. The software is intuitive, and operations are seamless. Fast engraving speed boosts my workflow. Solid build, highly reliable!

Ming Johnson –

As a laser engraver user, I give this machine 5 stars. The engraving results are precise and stunning. The software is intuitive, and operations are smooth. Fast engraving speed boosts my productivity. Top-notch craftsmanship and reliability!

Gabriela Wang (verified owner) –

**Performance & User Experience Review:**

The ThunderLaser Pro 40W excels on wood (crisp engraving at 500mm/s), acrylic (smooth edges), and leather (light charring at lower speeds). Precision is stellar (0.05mm), ideal for intricate designs like engraved wooden coasters. Setup was tool-less in 15 minutes, but LightBurn software required tutorials for vector optimization. The rotary attachment shines for tumblers. **Pros:** Speed, precision, material versatility. **Cons:** Leather settings need trial-and-error; air assist isn’t bundled. For $1,799, it’s a workhorse for small businesses, though rookies might crave more presets.

Patricia Suzuki (verified owner) –

The laser engraver stands out with its impressive technical specifications, boasting high power output that handles thick acrylic sheets effortlessly and 1200 DPI resolution for intricate metal engravings. Its spacious workspace accommodates large projects, enhancing versatility. From a value perspective, despite the higher initial investment, it offers excellent ROI with reduced maintenance costs and consistent performance. A minor suggestion is the addition of a cooling system for prolonged use to prevent overheating, ensuring sustained productivity without compromising quality.

Margot Persson (verified owner) –

The laser engraver excels in versatility, delivering crisp results on wood, acrylic, and leather with adjustable power settings for optimal material interaction. Its precision is notable, achieving clean engravings at high speeds, ideal for detailed projects like custom jewelry tags or signage. The software interface is intuitive, streamlining design uploads and adjustments, though a steeper learning curve may exist for advanced features. Perfect for small businesses and artists seeking efficient, professional-grade engraving solutions.

Saki Fischer (verified owner) –

**Laser Engraver Experience: Decorative Signage Production**

As a small business owner specializing in custom signage, I’ve found the laser engraver to be an invaluable tool for creating decorative items that stand out. My projects often involve materials like glass and leather, each presenting unique challenges and requiring different approaches.

**Specific Project Experience:**

– **Materials Used:** Glass and leather are popular choices for high-end signage. Glass offers a sleek, modern look, while leather provides a classic, elegant feel.

– **Challenges Encountered:** With glass, maintaining consistency across large batches was initially tricky due to variations in thickness. For leather, achieving precise detail without scorching the material proved challenging, especially with darker hues.

– **Solutions Implemented:** I adjusted the laser’s power settings for different glass thicknesses and experimented with slower speeds on leather to avoid burning. Regular maintenance of the laser head ensured consistent performance.

**Technical Performance:**

– **Power and Precision:** The engraver’s adjustable power settings allowed me to handle delicate materials like glass without cracking them. Precision was key, especially for intricate designs.

– **Software Experience:** While there was a learning curve, the software became efficient over time. Features like batch processing streamlined production, and custom settings tailored to each project saved significant setup time.

– **Special Features Utilized:** The adjustable focus feature helped maintain clarity across varying materials, while different nozzle sizes allowed for detailed work on leather and broader cuts on glass.

**Business Impact:**

– **Workflow Improvement:** The laser engraver has boosted our production capacity, allowing us to handle larger orders efficiently. Quality control is now more consistent, reducing returns.

– **Customer Satisfaction:** Customers appreciate the enhanced quality and faster turnaround times, leading to positive feedback and repeat business.

– **Cost-Effectiveness:** Compared to manual methods, the laser engraver has reduced material waste and labor costs, offering a solid return on investment.

In summary, transitioning from manual engraving to this laser system has transformed our operations. It’s not just more efficient; it’s also elevated the quality of our products, making us a go-to choice for custom signage.

Barbara Johnson –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Richard Gonzalez –

“Exceptional laser engraver! Precise cuts, intuitive software, swift operation, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Soo Schmidt –

“This laser engraver exceeds expectations! Impressive precision in every detail, intuitive software, and robust performance. A true workhorse with flawless craftsmanship.”

William Bernard –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & smooth operation. Fast, efficient, and built to last. Highly recommend!”

Jung Hernandez (verified owner) –

I absolutely love my LaserHawk LH2! It’s so user-friendly and precise, I was able to create intricate jewelry designs with ease. Highly recommend for any hobbyist looking to get into laser engraving—it’s a game-changer!

Jean Wagner –

★★★★★ Exceptional Laser Engraver! Superb engraving precision & quality. User-friendly software & smooth operation. Fast speeds boost productivity. Sturdy build, highly reliable.