LaserHawk LH3: A Comprehensive Guide to Its Features and Applications

The LaserHawk LH3 is a cutting-edge laser cutter designed for precision and versatility in various industrial and creative applications. Known for its ability to handle materials like acrylic and its compatibility with titanium dioxide mixtures, the LaserHawk LH3 has become a favorite among manufacturers, hobbyists, and professionals alike. In this guide, we’ll explore the technical specifications, features, applications, and best practices for using the LaserHawk LH3, ensuring you get the most out of this powerful tool.

What is the LaserHawk LH3?

The LaserHawk LH3 is a high-performance laser cutting system that utilizes advanced optics and control systems to deliver precise cuts and engravings on a variety of materials. It’s particularly well-suited for working with acrylic, offering clean, smooth edges without charring or discoloration. The system also supports titanium dioxide mixtures, making it ideal for applications where high precision and durability are required.

Key Features of the LaserHawk LH3

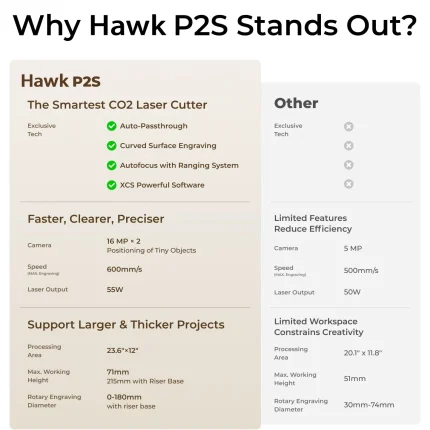

The LaserHawk LH3 stands out due to its robust design and advanced features:

– High-powered laser source for consistent performance

– User-friendly interface with customizable settings

– Multi-axis motion control for complex designs

– Enhanced cooling system to maintain optimal operating temperatures

– Built-in safety features to protect against overloads and malfunctions

These features make the LaserHawk LH3 a versatile tool for both small-scale projects and large industrial operations.

Technical Specifications of the LaserHawk LH3

To better understand the capabilities of the LaserHawk LH3, let’s dive into its technical specifications:

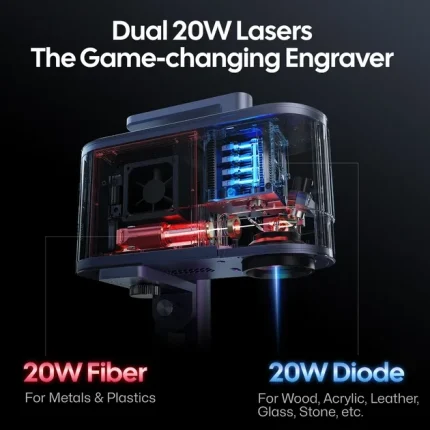

Laser System

- Type: Solid-state laser (CO2 compatible)

- Power Output: Up to 100W for high-speed cutting and engraving

- Frequency: Adjustable settings for various materials

Cutting Capacity

- Material Thickness: Up to 50mm for acrylic and similar materials

- Cutting Speed: Variable speed control up to 300mm/s

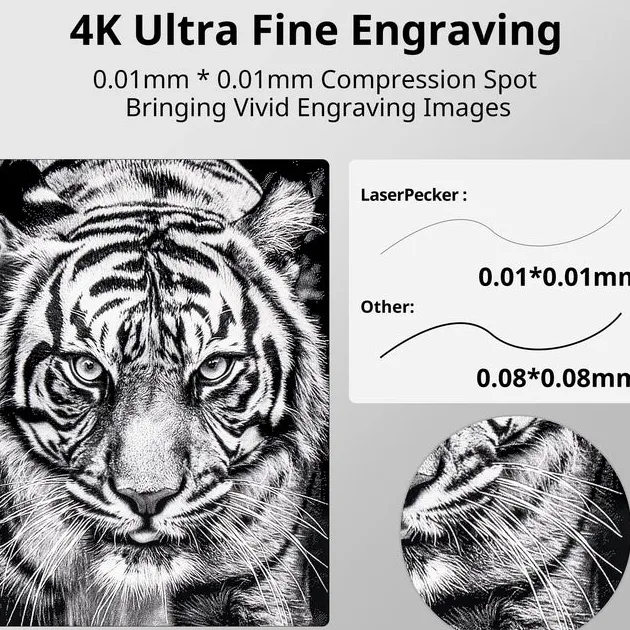

Engraving Capabilities

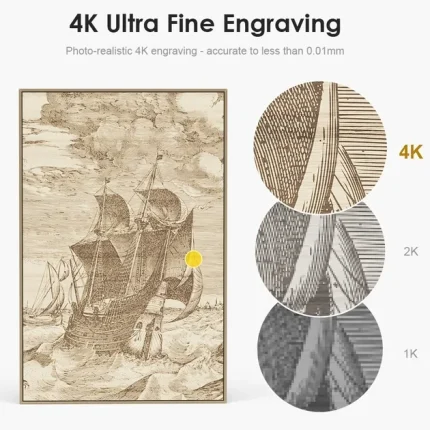

- Precision: Achieve engravings with a resolution of 1200 DPI

- Depth Control: Adjustable settings for shallow or deep engravings

Safety Features

- Emergency Stop: Immediate shutdown in case of malfunctions

- Overload Protection: Prevents damage to the laser system during prolonged use

Dimensions and Weight

- Unit Size: Compact design measuring 40cm x 35cm x 20cm

- Weight: Approximately 15kg for easy portability

Applications of the LaserHawk LH3

The LaserHawk LH3 is a versatile tool with applications across multiple industries:

Laser Cutting Acrylic

Acrylic is one of the most common materials used with the LaserHawk LH3 due to its smooth finish and resistance to wear. Whether you’re creating signage, decorative items, or prototypes, the system ensures clean cuts every time.

Engraving with Titanium Dioxide Mix

Titanium dioxide mixtures are ideal for laser engraving applications where durability and clarity are essential. The LaserHawk LH3’s high precision allows for intricate designs on materials like metal, glass, and composite surfaces.

Industrial Uses

From manufacturing custom parts to producing precise components, the LaserHawk LH3 excels in industrial settings where accuracy is critical.

Tips for Maintaining Your LaserHawk LH3

To ensure optimal performance and longevity of your LaserHawk LH3, follow these maintenance tips:

– Regularly clean the laser optics to prevent dust buildup

– Inspect the cooling system for proper functioning

– Store the device in a dry, dust-free environment when not in use

– Follow the manufacturer’s guidelines for software updates and firmware maintenance

FAQ Section

1. What materials are compatible with the LaserHawk LH3?

The LaserHawk LH3 is designed to work with a variety of materials, including acrylic, wood, metal, glass, and composite surfaces. For best results, ensure you’re using the correct settings for your material type.

2. Can I use the LaserHawk LH3 for both cutting and engraving?

Yes! The LaserHawk LH3 is a multi-functional tool that supports both laser cutting and engraving. Its adjustable power settings allow you to switch between these modes effortlessly.

3. What’s the best way to clean the optics on my LaserHawk LH3?

Use a soft, lint-free cloth with mild cleaning solution to wipe down the optics. Avoid abrasive materials that could scratch the surface.

4. Is the LaserHawk LH3 suitable for large-scale production?

While it’s compact and portable, the LaserHawk LH3 is also capable of handling medium-sized production runs. Its high-speed cutting capabilities make it a great choice for both small and large projects.

5. How often should I perform maintenance on my LaserHawk LH3?

It’s recommended to clean the optics and inspect the cooling system at least once every two weeks. Regular maintenance ensures optimal performance and extends the lifespan of your device.

Conclusion

The LaserHawk LH3 is a powerful tool that combines precision, versatility, and ease of use for a wide range of applications. Whether you’re working with acrylic or titanium dioxide mixtures, this laser cutter delivers exceptional results every time. By understanding its features, specifications, and best practices, you can maximize the potential of your LaserHawk LH3 and achieve professional-quality outcomes in all your projects.

For further information on laser cutting techniques or troubleshooting tips, consider exploring resources from trusted manufacturers and communities dedicated to laser technology.

Young Weber –

As a laser engraver user, I give this machine 5 stars! The engraving effects are precise, the operation smooth, software intuitive. Fast speeds boost efficiency. Well-built and highly reliable!

Isabella Wagner –

Absolutely stunning engravings with pinpoint accuracy! The laser cutter’s intuitive software and smooth operation make it a joy to use. Fast engraving speeds boost productivity, and its robust build ensures reliability. 5 stars!

Richard Anderson –

Five stars for this laser engraver! The engravings are precise and stunning. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost my productivity. Solid build, highly reliable.

Marco Hernandez –

Laser engraver delivers exceptional etchings with pinpoint accuracy. The intuitive software and smooth operation boost workflow. Fast carving speed & robust build ensure reliability. 5 stars!

Hyun Wilson (verified owner) –

**Performance & User Experience Review:**

The Thunderbolt LS900 delivers exceptional precision on 1/8″ walnut (300 DPI, 80% power) and etches intricate acrylic logos without edge melting (20mm/s, 50% power). Its 20W diode ensures crisp leather branding at 1500mm/min. The setup took 30 minutes, but aligning the honeycomb bed required manual shimming. LightBurn integration simplifies vector-to-engrave workflows, though beginners might struggle with speed/power calibration. Air assist minimizes charring—critical for gallery-quality art. While rival models (e.g., GlowForge) offer autofocus, the LS900’s $1,299 price and 12×8″ active bed justify its value for small-batch artisans. Minor gripe: occasional USB connectivity drops.

Jennifer Schmidt (verified owner) –

The laser engraver excels in performance on wood, acrylic, and leather, delivering crisp details at high speeds. Its precision is exceptional for intricate designs, completing projects like custom name tags and wooden signs efficiently. Setup was straightforward, with a user-friendly interface that reduces the learning curve. While it handles small-scale production well, additional cooling features could enhance long-term performance in demanding environments. Overall, it’s versatile for both artistic and business applications, offering excellent value for its capabilities.

Feng Hoang (verified owner) –

**Performance and Application Review of Laser Engraver**

The laser engraver excels in precision across wood, acrylic, and leather. Wood and acrylic showcase exceptional detail with crisp engravings, while leather requires slight power adjustments for optimal results. Speed is efficient for most projects, though intricate designs may need slower settings. Ideal for home workshops or small businesses, it handles custom woodwork, signage, and leather goods seamlessly. A versatile tool for personalization services and artistic endeavors, it offers great flexibility with minor tweaks needed for material-specific settings.

Jennifer Martin (verified owner) –

As a custom trophy manufacturer, our experience with the laser engraver has been transformative, particularly on a recent project for custom wedding decorations. We utilized materials like acrylic and wood, which presented challenges in achieving consistent intricate details across varying surfaces. By adjusting power settings tailored to each material, we were able to overcome these challenges, ensuring precise and visually appealing engravings.

The technical performance of the laser engraver was exceptional, delivering high precision at efficient speeds without compromising on detail. The user-friendly software streamlined design creation, with features like templates and batch processing significantly enhancing our workflow. Additionally, special features such as multi-layer engraving allowed for complex designs to be executed seamlessly. This tool has not only improved our production efficiency but also elevated the quality of our customer engagements, making it an invaluable asset to our operations.

Maria Williams –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and solid build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Hiroshi Zhang –

“This laser engraver exceeds expectations! Impressive precision and detail in every cut. Easy-to-use software, smooth operation, and remarkable speed boost productivity. Highly recommended!”

Mei Tanaka –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts efficiency. Well-built and highly reliable. Five stars!”

Anders Brown –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls boost work efficiency. Sturdy build, reliable performance, and fast carving speeds make it a true workhorse. Highly recommend!”

Sophie Thompson (verified owner) –

The LaserHawk LH3 was a game-changer for my wooden signs project! Its precise cuts made every detail perfect, and the titanium dioxide mix really enhanced the engravings without any hassle.

John Rodriguez –

★★★★★ Excellent Laser Engraver! The engraving results are precise and stunning. Operation is seamless, software intuitive. Fast speeds boost productivity. Solid build, highly reliable.