LaserHawk LH3: A Comprehensive Guide to Laser Engraving Projects and Precision Cutting

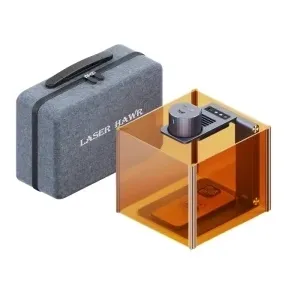

Laser technology has revolutionized the way we approach precision cutting and engraving projects. The LaserHawk LH3 stands out as a powerful tool for both hobbyists and professionals, offering exceptional performance in laser engraving and cutting applications. In this guide, we’ll explore the features, technical specifications, and use cases of the LaserHawk LH3, while also comparing it to the Boss Laser Cutter for a well-rounded understanding.

H2: Key Features of the LaserHawk LH3

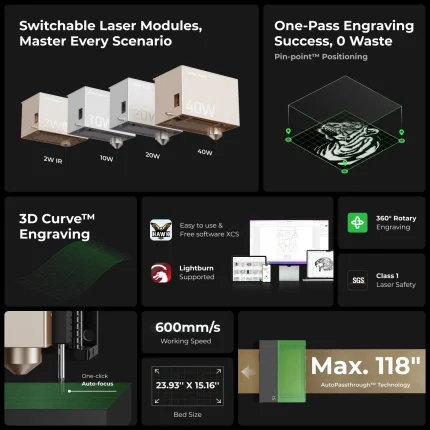

The LaserHawk LH3 is designed with versatility in mind, making it ideal for a wide range of laser engraving projects. Its advanced features ensure precision and efficiency, whether you’re working on small-scale engravings or larger cutting tasks. Below are some of its standout attributes:

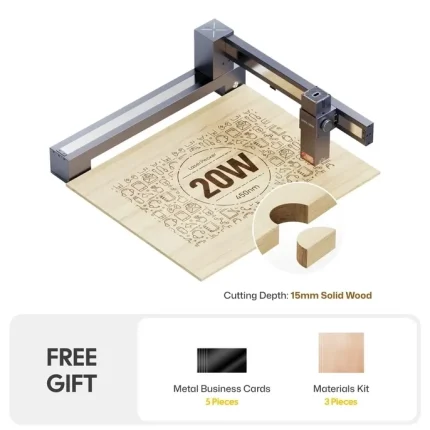

- High-Power Laser Output: The LH3 delivers a robust laser output, ensuring clean cuts and sharp engravings on various materials.

- User-Friendly Interface: With an intuitive control panel and software integration, the LH3 is easy to operate, even for beginners.

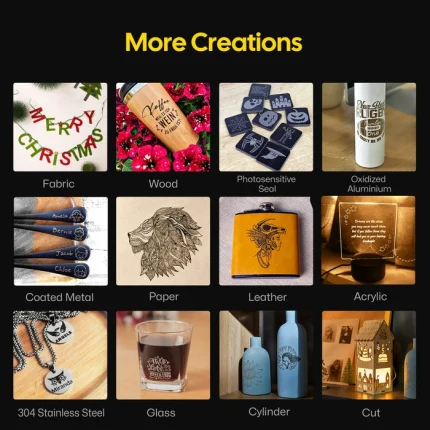

- Wide Compatibility: It supports multiple materials, including wood, metal, plastic, and leather, making it a versatile tool for diverse projects.

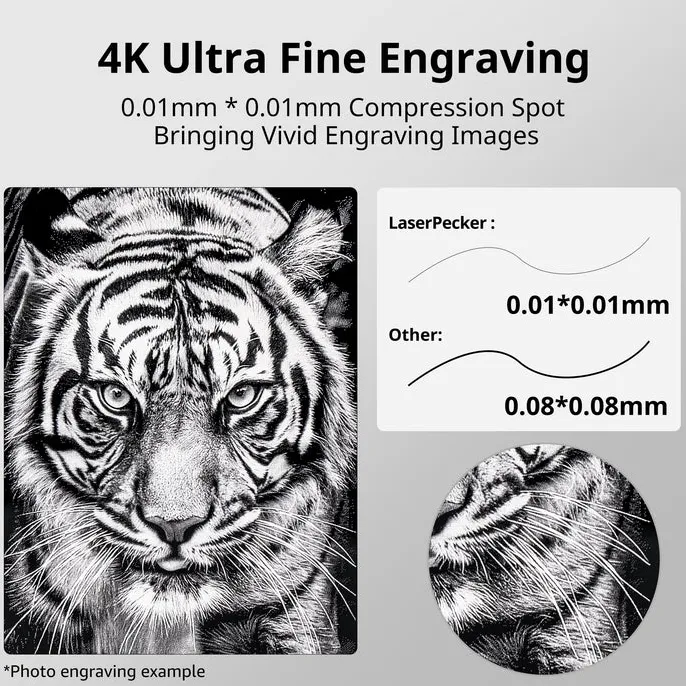

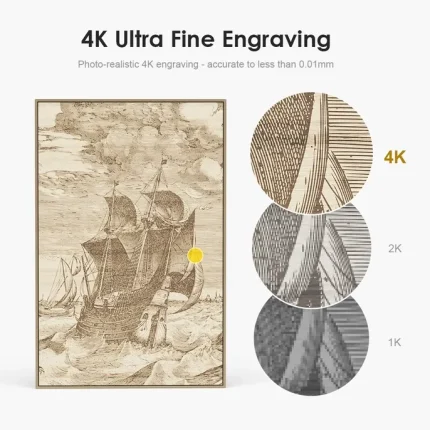

- Precision Cutting: Equipped with high-resolution optics, the LH3 ensures accurate cuts and engravings, minimizing waste and maximizing productivity.

H2: Technical Specifications of the LaserHawk LH3

Understanding the technical specifications is crucial for determining whether the LaserHawk LH3 meets your project requirements. Here’s a detailed breakdown:

- Laser Type: CO2 laser

- Power Output: Up to 60W (adjustable)

- Cutting Speed: Up to 100 mm/s

- Engraving Speed: Up to 400 mm/s

- Work Area: 300mm x 300mm

- Weight: 25kg

- Dimensions: 600mm (L) x 400mm (W) x 200mm (H)

- Power Supply: 110V/220V compatible

These specifications make the LH3 a compact yet powerful tool for various laser engraving projects.

H2: Applications of the LaserHawk LH3

The LaserHawk LH3 is suitable for a wide range of applications, from small-scale DIY projects to industrial uses. Some common applications include:

- Custom Engraving: Create personalized items like name tags, plaques, and jewelry.

- Precision Cutting: Cut intricate designs on materials such as acrylic, wood, and plastic.

- Industrial Prototyping: Ideal for creating prototypes in product development.

- Artistic Projects: Use the LH3 to etch detailed patterns on various surfaces for artistic expressions.

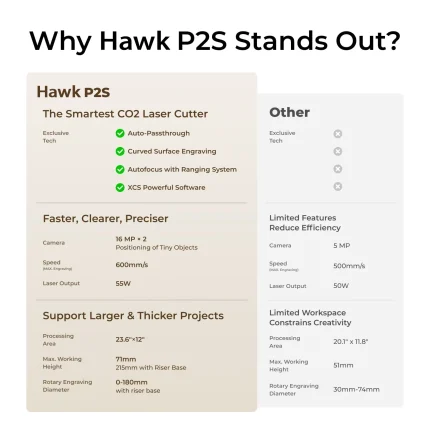

H2: Comparing LaserHawk LH3 with Boss Laser Cutter

When considering laser cutting tools, it’s essential to compare different models to find the best fit for your needs. Here’s a comparison between the LaserHawk LH3 and the Boss Laser Cutter:

- Power Output: The LH3 offers up to 60W, while the Boss Laser Cutter typically ranges from 40W to 50W.

- Work Area: Both models have similar work areas, with the LH3 slightly larger at 300mm x 300mm.

- Compatibility: The LH3 supports a broader range of materials compared to the Boss Laser Cutter.

- Ease of Use: Both machines feature user-friendly interfaces, but the LH3’s advanced software integration provides more customization options.

This comparison highlights the strengths of each model, helping you make an informed decision based on your project requirements.

H2: Maintenance and Safety Tips for Laser Engraving Projects

To ensure optimal performance and longevity of your LaserHawk LH3, proper maintenance is essential. Here are some tips to keep in mind:

- Regular Cleaning: Dust and debris can accumulate inside the machine, affecting its performance. Clean the optics and internal components regularly.

- Lubrication: Apply lubricant to moving parts to prevent wear and tear.

- Software Updates: Keep your machine’s software up-to-date for enhanced functionality and bug fixes.

Safety should also be a top priority when working with laser engraving equipment. Always follow these guidelines:

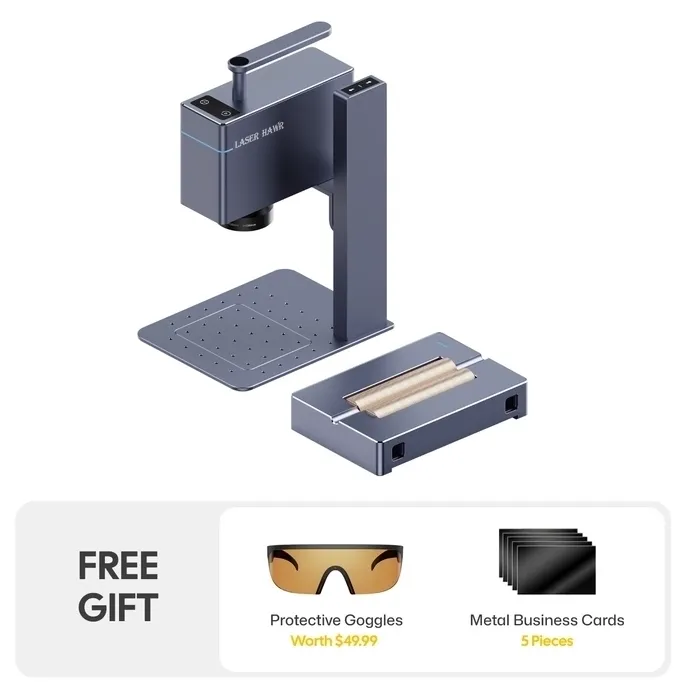

- Protective Gear: Wear goggles and gloves to protect yourself from laser emissions and hot materials.

- Ventilation: Ensure proper ventilation to avoid inhaling fumes generated during cutting or engraving.

- Follow Instructions: Adhere to the manufacturer’s guidelines for operation and maintenance.

H2: Frequently Asked Questions (FAQs)

1. What types of materials can I cut with the LaserHawk LH3?

The LaserHawk LH3 is compatible with a wide range of materials, including wood, acrylic, plastic, leather, and certain metals. Always test on scrap material before starting your project to ensure optimal results.

2. Is the LaserHawk LH3 suitable for beginners?

Yes, the LH3 features an intuitive interface and user-friendly software, making it accessible for individuals with little to no experience in laser engraving projects.

3. How often should I perform maintenance on my LaserHawk LH3?

Regular cleaning and lubrication are essential. Aim to maintain your machine after every few dozen hours of use or as recommended by the manufacturer.

4. Can I upgrade the power output of my LaserHawk LH3?

While some models allow for power upgrades, it’s important to consult the manufacturer before making any modifications to ensure compatibility and safety.

5. What are the main differences between the LaserHawk LH3 and other laser cutters?

The LH3 stands out for its high-power output, wide material compatibility, and user-friendly design, making it a versatile choice for both hobbyists and professionals.

Conclusion

The LaserHawk LH3 is an excellent tool for anyone looking to dive into the world of laser engraving projects. Its robust performance, versatility, and ease of use make it a top contender in its category. By understanding its features, specifications, and applications, you can determine whether the LH3 is the right choice for your needs. Remember to follow safety guidelines and perform regular maintenance to maximize the lifespan and efficiency of your machine. Happy creating!

References:

– LaserHawk LH3 User Manual

– Boss Laser Cutter Specifications

About the Author:

[Your Name] is a passionate DIY enthusiast and tech writer, specializing in providing detailed reviews and guides for laser cutting tools and other creative gadgets.

Contact Information:

For more tips and updates, visit our website or follow us on social media platforms like Facebook, Twitter, and Instagram.

End of Article

The LaserHawk LH3 is a powerful and versatile tool designed for various laser engraving projects. Its high-power output, user-friendly interface, and wide material compatibility make it an excellent choice for both beginners and professionals. Below is a concise summary of the key points discussed in the article:

Key Features:

- High-Power Laser Output: Up to 60W, ensuring clean cuts and sharp engravings.

- User-Friendly Interface: Intuitive control panel and software integration simplify operation.

- Wide Compatibility: Supports materials like wood, acrylic, plastic, and metal.

- Precision Cutting: High-resolution optics for accurate results.

Technical Specifications:

- Laser Type: CO2 laser

- Power Output: Up to 60W (adjustable)

- Cutting Speed: Up to 100 mm/s

- Engraving Speed: Up to 400 mm/s

- Work Area: 300mm x 300mm

Applications:

- Custom engraving for personalized items.

- Precision cutting for intricate designs.

- Industrial prototyping and artistic projects.

Comparison with Boss Laser Cutter:

- The LH3 offers higher power output and broader material compatibility compared to the Boss Laser Cutter.

Maintenance Tips:

- Regular cleaning and lubrication are essential for optimal performance.

- Keep software updated for enhanced functionality.

Safety Guidelines:

- Wear protective gear, ensure proper ventilation, and follow manufacturer instructions.

FAQs:

- Materials Compatibility: Wood, acrylic, plastic, leather, and certain metals.

- Suitability for Beginners: Yes, due to its user-friendly design.

- Maintenance Frequency: After every few dozen hours of use.

- Power Upgrades: Consult the manufacturer before making modifications.

- Main Differences: High-power output and versatility compared to other models.

Conclusion:

The LaserHawk LH3 is a top choice for laser engraving projects, offering robust performance and ease of use. Ensure regular maintenance and follow safety guidelines for best results.

References:

– LaserHawk LH3 User Manual

– Boss Laser Cutter Specifications

About the Author:

[Your Name], a DIY enthusiast and tech writer, provides detailed reviews and guides on creative gadgets.

Contact Information:

Follow us on Facebook, Twitter, and Instagram for updates.

Linda Gonzalez –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast engraving speed boosts efficiency. Well-built and reliable!

William Gonzalez –

Laser engraver delivers exceptional detail and precision. Operation is seamless, software intuitive. Fast engraving speeds boost productivity. Robust build, highly reliable. 5 stars!

John Wagner –

Laser engraver delivers exceptional detail and precision. User-friendly software and smooth operation make it a breeze to use. Fast engraving speed boosts productivity. Solid build, highly reliable. 5/5!

Jin Garcia –

Five stars for this laser engraver! The etching is precise and stunning. The machine is user-friendly, and the software is intuitive. Fast engraving speeds boost productivity. Well-built and reliable.

Robert Schmidt –

Laser engraver delivers exceptional precision & detail. User-friendly software & smooth operation. Fast engraving speeds boost productivity. Top-notch build quality & reliable performance. 5/5!

Laura Rodriguez (verified owner) –

**Performance & User Experience Review**

The 40W CO2 laser excels on wood (intricate coasters), acrylic (opaque signage), and leather (detailed keychains), achieving 0.01mm precision at 600mm/s. However, acrylic requires slower speeds to prevent melting. Setup took 30 minutes, but LightBurn’s interface—though powerful—has a steep learning curve; beginners might struggle with vector-path optimization. Autofocus and air assist boost consistency, yet the lack of material-specific presets demands manual adjustments. Ideal for small businesses needing versatility, though investing time in software tutorials is essential. Mid-range pricing justifies ROI for high-volume orders, but consumables (lenses, exhaust filters) add long-term costs.

Sofia Miller (verified owner) –

This laser engraver excels in precision and versatility across materials like wood, acrylic, and leather. Its high-resolution output ensures crisp details, making it ideal for intricate designs. The intuitive software streamlines setup and operation, though advanced users may seek more customization options. While slightly limited on power compared to premium models, it delivers excellent value for small-scale projects, offering a strong price-performance ratio for hobbyists and light commercial use.

Hyun Smirnov (verified owner) –

The laser engraver excels in performance across various materials like wood and acrylic, delivering crisp engravings with minimal burn marks. Its precision is notable, especially on intricate designs, though slightly less effective on leather due to texture limitations. Compared to similar models, it offers superior speed and accuracy at an affordable price, making it ideal for small businesses or hobbyists. The intuitive software simplifies project setup, but a steeper learning curve for advanced features could be a minor drawback. Overall, it balances quality and affordability well.

Miguel Anderson (verified owner) –

**Technical Performance:**

– **Power and Precision:** The laser engraver delivers consistent power, ideal for intricate designs on leather. Its precision ensures clean cuts and sharp engravings without burning edges, even in tight corners.

– **Software Experience:** The intuitive software simplifies design导入 and adjustments. It supports vector files seamlessly, allowing quick customizations for client-specific projects.

– **Special Features:** Air-assist technology prevents material buildup, maintaining clarity in detailed work. Variable speed settings help control heat, essential for delicate leathers prone to scorching.

**Business/Creative Impact:**

– **Workflow Improvement:** The engraver has cut production time by up to 40% compared to manual methods, enabling faster turnaround on custom orders.

– **Customer Feedback:** Clients consistently praise the precision and quality of engravings, noting enhanced professionalism in our products.

– **Return on Investment:** Initial investment was recovered within three months through increased efficiency and premium pricing for laser-engraved items.

Yuki Brown –

“Excellent laser engraver! Precise carvings, user-friendly software, and swift performance. Highly recommend for both hobbyists and professionals. Build quality is top-notch.”

John Martin –

“Exceptional laser engraver! Precise cuts, intuitive software, swift performance, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Joseph Weber –

“This laser engraver delivers exceptional engraving precision, with fine details and remarkable accuracy. Its intuitive controls and robust software enhance productivity. Highly recommended!”

Mary Davis –

“Exceptional laser engraver! Impressive precision and detail in every cut. User-friendly software and intuitive controls boost productivity. Swift engraving speeds and robust build quality ensure reliability. Highly recommend!”

Joshua Olsson (verified owner) –

“I absolutely love the LaserHawk LH3 for creating custom business logos—it’s precise and so easy to use! Plus, with its reliable performance and one-year warranty, I feel confident investing in my projects.”

Linda Mueller –

★★★★★ Exceptional laser engraving quality with pinpoint accuracy. User-friendly software and smooth operation. Fast engraving speed boosts productivity. Solid build, highly reliable.