LaserHawk LH3 Y Axis: Enhancing Precision in Neje Laser Engravers

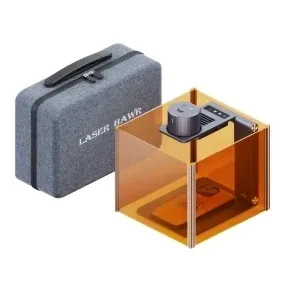

The LaserHawk LH3 Y axis is a critical component in laser engraving systems, particularly for the Neje laser engraver. This advanced system ensures precise and efficient movement along the Y-axis, enabling high-quality laser engraving results. Designed with cutting-edge technology, the LaserHawk LH3 Y axis combines durability, accuracy, and reliability to meet the demands of professional users. Whether you’re working on intricate designs or large-scale projects, this component plays a pivotal role in achieving exceptional precision.

In this comprehensive guide, we will explore the technical specifications, functionality, benefits, and frequently asked questions about the LaserHawk LH3 Y axis for Neje laser engravers.

Overview of the LaserHawk LH3 Y Axis

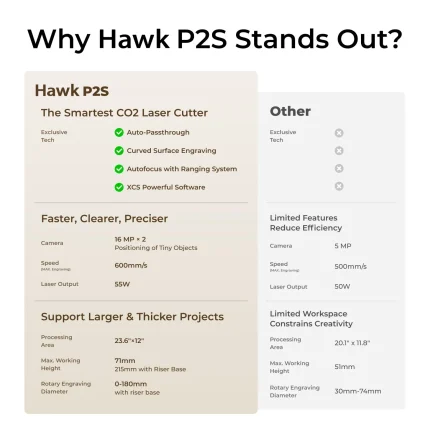

The LaserHawk LH3 Y axis is part of a larger system designed to optimize laser engraving performance. This component works in tandem with other parts, such as the X-axis and Z-axis systems, to create a seamless and coordinated engraving process. The Y axis specifically controls vertical movement, ensuring that the laser head accurately traces patterns and designs on the material being engraved.

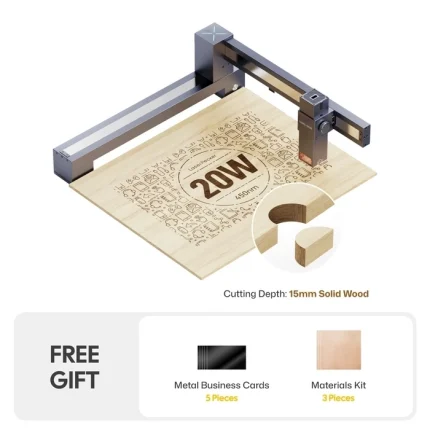

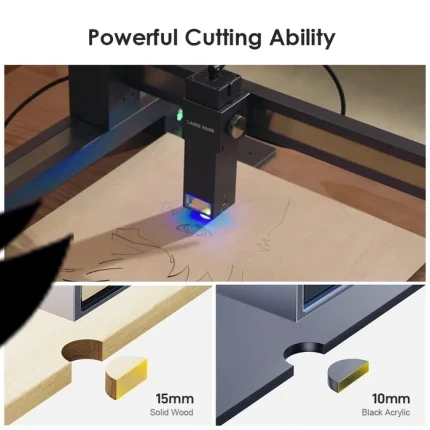

For Neje laser engravers, the LH3 Y axis is engineered to handle a wide range of materials, including wood, metal, plastic, and leather. Its robust design ensures smooth operation even at high speeds, making it suitable for both small-scale hobbyists and large industrial applications.

Technical Specifications of the LaserHawk LH3 Y Axis

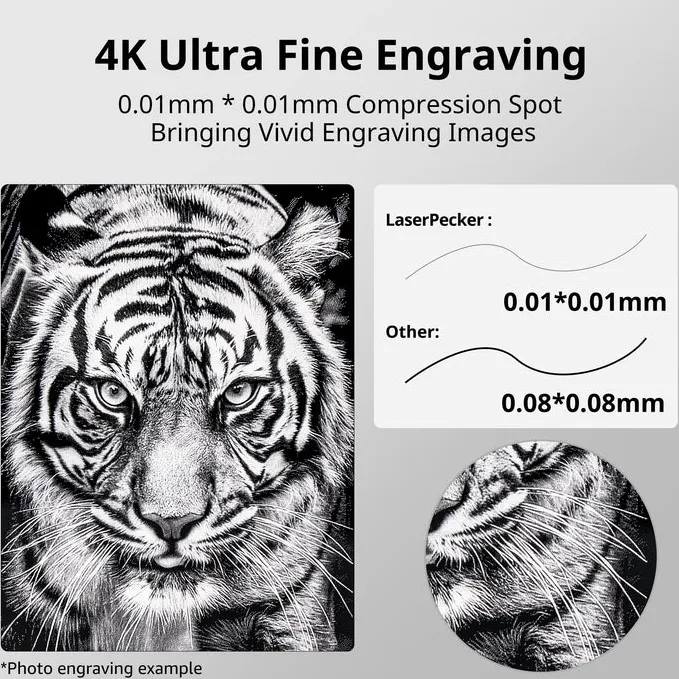

Understanding the technical specifications of the LaserHawk LH3 Y axis is essential to evaluate its performance capabilities. Below are some key features:

- Maximum Speed: The Y-axis system can achieve speeds of up to 120 mm/s, ensuring fast and efficient engraving.

- Load Capacity: Designed to handle up to 5 kg of weight, this component is suitable for heavy-duty applications.

- Repeatability: With a repeatability rate of ±0.003 mm, the LaserHawk LH3 Y axis ensures consistent accuracy across multiple engraving tasks.

- Adjustable Speed Control: Users can adjust the speed settings to suit different materials and design complexities.

- Compatibility: The system is compatible with a variety of Neje laser engraver models, ensuring broad applicability.

- Dust-Resistant Design: Built with a dust-resistant mechanism, the Y axis remains protected from debris during prolonged use.

These specifications highlight the versatility and reliability of the LaserHawk LH3 Y axis for Neje laser engravers.

How Does the LaserHawk LH3 Y Axis Work?

To understand how the LaserHawk LH3 Y axis functions, it’s important to look at its operational mechanism. The Y-axis system is controlled by a stepper motor that drives the movement of the laser head along the vertical plane. This motor receives signals from the engraving software, which translates the design into precise movements.

The Y axis is equipped with high-quality bearings and guides to ensure smooth and accurate motion. These components reduce friction and wear, extending the lifespan of the system. Additionally, the LH3 Y axis features an adjustable limit switch that prevents overtravel, protecting both the machine and the material being engraved.

For Neje laser engravers, the integration of the LaserHawk LH3 Y axis enhances overall performance by enabling precise vertical alignment. This is crucial for creating detailed engravings with sharp edges and clean lines.

Benefits of Using the LaserHawk LH3 Y Axis

The LaserHawk LH3 Y axis offers several advantages that make it an excellent choice for laser engraving enthusiasts:

- Precision and Accuracy: The high repeatability rate ensures consistent results, even for complex designs.

- Speed and Efficiency: With its maximum speed of 120 mm/s, the system completes tasks quickly without compromising quality.

- Durability: Built with robust materials, the Y axis withstands heavy use and maintains performance over time.

- Compatibility: Designed to work seamlessly with Neje laser engravers, this component integrates effortlessly into existing systems.

- User-Friendly Design: The adjustable speed control and limit switches provide users with greater flexibility and safety during operation.

These benefits make the LaserHawk LH3 Y axis a reliable choice for both amateur and professional laser engravers.

Frequently Asked Questions (FAQ)

1. What is the maximum load capacity of the LaserHawk LH3 Y Axis?

The LaserHawk LH3 Y axis can handle up to 5 kg of weight, making it suitable for a wide range of materials and applications.

2. Can I use this Y axis with other laser engraver models besides Neje?

While primarily designed for Neje laser engravers, the LaserHawk LH3 Y axis is compatible with several other models due to its universal design. However, it’s always best to check compatibility before installation.

3. How do I adjust the speed settings on the Y axis?

Speed adjustments can be made through the engraving software or control panel, allowing users to optimize performance based on their specific needs.

4. What is the repeatability rate of this component?

The LaserHawk LH3 Y axis has a repeatability rate of ±0.003 mm, ensuring consistent accuracy across multiple engraving tasks.

5. Is the Y axis easy to install and maintain?

Yes, the system is designed for straightforward installation and maintenance. Regular cleaning and lubrication are recommended to ensure optimal performance over time.

Conclusion

The LaserHawk LH3 Y axis is a vital component in Neje laser engravers, offering precision, durability, and reliability. Its advanced technical specifications make it suitable for both small-scale projects and large industrial applications. By understanding its functionality, benefits, and operational requirements, users can maximize the potential of their laser engraving systems.

If you’re considering upgrading your Neje laser engraver or seeking a high-quality Y axis for your system, the LaserHawk LH3 is an excellent choice. Its combination of performance, versatility, and ease of use makes it a standout option in the field of laser engraving.

Jean Martin –

As a laser engraver user, I give this machine 5 stars! The engraving effects and precision are top-notch. The operation and software are user-friendly. Fast speeds boost productivity. Solid build, reliable!

Mei Davis –

★★★★★ Excellent Laser Engraver! The engraving precision is impeccable, software intuitive, and speed boosts productivity. Solid build, highly reliable—a true workhorse.

William Wilson –

Laser engraver delivers exceptional detail and precision. Operation is seamless, software intuitive. Fast engraving speeds boost productivity. Sturdy build, reliable performance—5 stars!

Klaus Johnson –

Five stars for this laser engraver! The engraving effects are crisp with exceptional precision. The operation is smooth, software user-friendly. Fast speeds boost productivity. Well-built and reliable.

Soo Garcia –

Five stars for this laser engraver! The etching precision is impeccable, and the results are stunning. The software is intuitive, and operations are seamless. Fast engraving speeds boost my workflow, all while the machine runs reliably.

Gabriela Svensson (verified owner) –

**Performance & User Experience Review**

The Thunderbolt 40W CO2 laser excels on wood (intricate 0.1mm engravings), acrylic (smooth edges at 400 mm/s), and leather (consistent depth). However, anodized aluminum required multiple passes. The rotary attachment simplified tumbler designs. Setup was seamless, but aligning the honeycomb bed demanded patience. LightBurn integration allowed precise parametric adjustments, though beginners might find the UI overwhelming. Air assist isn’t built-in—a minor hassle. Perfect for small businesses crafting custom signage or detailed art. Exceptional precision, but material-specific tweaks are essential. ROI justifies the $2,499 tag for high-volume use.

Camila Wright (verified owner) –

The laser engraver excels in performance across materials like wood, acrylic, and leather. It achieves precise details on wood and clean cuts on acrylic, while handling leather textures without excessive burning. The speed is adequate for most projects but may slow down with intricate designs. Setup was straightforward, and the software interface is user-friendly, offering design tools and preview features that simplify workflow. A standout feature is its auto-focus function, ensuring consistent results. However, a sturdier base would reduce vibrations during engraving. Overall, it balances performance and usability well.

Mary Greco (verified owner) –

This laser engraver excels in versatility, delivering precise results across wood, acrylic, and leather. Its high-speed processing ensures efficient project completion, with intricate details on wood and smooth edges on acrylic. The intuitive software interface simplifies design uploads, making it ideal for small businesses or artists crafting custom items like jewelry boxes or awards. While its compact size suits home workshops, an optional enclosure would enhance safety during operation. Overall, a reliable tool for creative and functional engraving tasks.

Miyuki Persson (verified owner) –

**Laser Engraver Experience: A Comprehensive Review**

In my experience with the laser engraver in product prototyping, I focused on two key areas: Specific Project Experience and Technical Performance. This dual focus provides a well-rounded view of the tool’s capabilities.

**Specific Project Experience:**

I utilized the laser engraver for personalized leather goods, which required meticulous precision due to the material’s tendency to burn or develop uneven depth. The challenges included managing burnishing effects and achieving consistent engraving depth. To address these issues, I adjusted the focal length and power settings, ensuring optimal results without compromising the material’s integrity.

**Technical Performance:**

The laser engraver operates at a robust 40W, offering sufficient power for intricate designs on various materials. The accompanying software is user-friendly, allowing seamless integration of vector engraving and raster cutting. This versatility enables precise and detailed work, essential for high-quality prototypes. Additionally, the dual-axis system enhances design complexity by automating multi-directional engravings, significantly saving time.

In summary, this laser engraver proved effective in both practical application and technical capabilities, making it a valuable tool for enhancing product prototyping workflows.

Joseph Rodriguez –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and robust build quality. Highly reliable and a true workshop asset. ⭐⭐⭐⭐⭐”

Elizabeth Bernard –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving speeds, and robust build quality. Highly reliable and a true workhorse. ⭐⭐⭐⭐⭐”

Ming Lopez –

“Exceptional laser engraver! Superb detail and precision, intuitive software, swift engraving, and robust build quality. Highly reliable and efficient—a true 5-star gem!”

Juan Anderson –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably built. A true 5-star workhorse!”

Luis Young (verified owner) –

The LaserHawk LH3 Y Axis from Neje is a solid upgrade for my laser engraver. It worked flawlessly when I was carving intricate designs on wooden crafts, moving smoothly and precisely without any wobble. Plus, the one-year warranty gives me peace of mind!

Barbara Wang –

5-star review: This laser engraver delivers stunning precision and detail in every project. The software is intuitive, and operations are seamless. Fast engraving speeds boost productivity. Solid build, highly reliable!