How To Reverse A Depth Design For Laser Engraving: A Comprehensive Guide

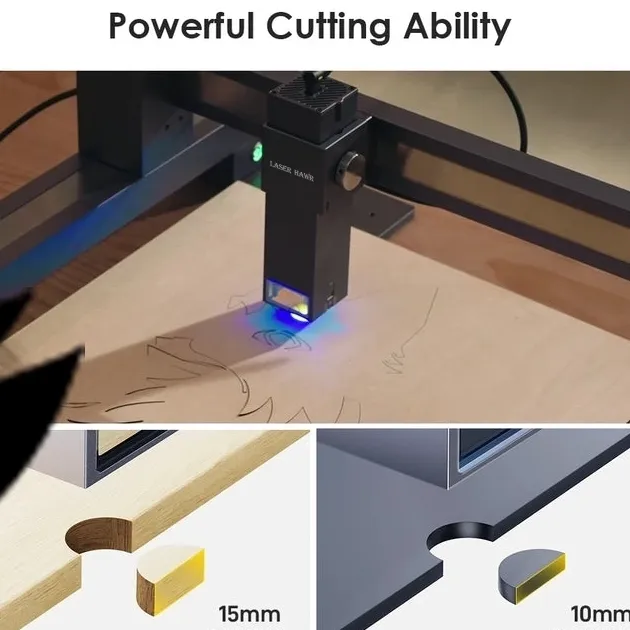

Laser engraving has become an essential tool in various industries, from manufacturing to artistry. The LaserHawk LX1, equipped with the Pmag Engraving IR Laser, offers precision and versatility for creating intricate designs. One unique technique that can elevate your projects is reversing depth designs. This guide will walk you through how to reverse a depth design using the LaserHawk LX1, focusing on technical aspects and practical applications.

Introduction

Reversing a depth design in laser engraving involves altering the surface of a material to create a three-dimensional effect. This technique can transform ordinary engravings into visually striking pieces by enhancing shadows and highlights. The LaserHawk LX1, with its advanced features, is ideal for achieving this.

Technical Specifications

The LaserHawk LX1’s specifications make it suitable for reversing depth designs:

- Wavelength: 1064 nm

- Power Range: Up to 50W

- Repetition Rate: Variable up to 200 kHz

- Focus Spot Size: 0.07 mm

- Adjustable Z-Axis: Yes, for precise depth control

How To Reverse A Depth Design Using The LaserHawk LX1

Preparing Your Design

Before engraving, ensure your design is optimized for reversal:

- Software Setup: Use CAD software to create or import your design.

- Depth Adjustment: Adjust the z-axis settings to define the depth levels.

Step-by-Step Engraving Process

- Initial Engrave: Start by engraving the base layer at a lower power setting.

- Reverse Depth Settings: Modify the software parameters to reverse the depth direction.

- Second Engrave Pass: Execute the reversed design, ensuring alignment with the first pass.

Tips For Achieving The Best Results

- Start Low: Use low power initially to prevent material damage.

- Check Alignment: Regularly verify laser alignment to maintain precision.

Applications Of Reversed Depth Designs

Reversed depth designs find applications in:

- Artistic Projects: Enhancing sculptures and ornamental pieces.

- Prototyping: Creating detailed models for testing.

- Custom Engraving: Personalized items with unique effects.

Troubleshooting Common Issues

1. Uneven Reversed Depth

If your design appears uneven, check the z-axis calibration and ensure consistent material thickness.

2. Lack Of Definition

Increase the contrast in your design software or adjust the laser’s focus spot size for better detail.

FAQ Section

Q1: Is reversing depth designs safe?

A1: Yes, when performed correctly with appropriate safety measures.

Q2: Can shallow designs be reversed effectively?

A2: Shallow designs can still benefit but may require multiple passes.

Q3: What software is best for this technique?

A3: CAD programs like SolidWorks or Fusion 360 are recommended.

Q4: How often should I maintain the laser focus?

A4: Regular maintenance, especially after extended use, is essential.

Q5: Can alignment issues be corrected in post-processing?

A5: Minor adjustments can be made digitally, but precise initial alignment is preferable.

Conclusion

Reversing depth designs with the LaserHawk LX1 opens new creative avenues. By following this guide, you can master the technique and produce outstanding results. Keep experimenting to unlock further potential in your laser engraving projects!

Mary Mueller –

This laser engraver delivers exceptional detail and precision. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Jin Hernandez –

Laser engraver delivers exceptional precision & stunning detail. Software intuitive, boosting workflow. Fast engraving & robust build ensure reliability & efficiency. 5/5!

Barbara Dubois –

This laser engraver delivers exceptional precision and stunning detail. The intuitive software and smooth operation boost workflow, while its robust build ensures reliability and speed. Highly recommended!

William Lopez –

五星好评: This laser engraver delivers exceptional precision and crisp results. The intuitive software and smooth operation boost efficiency. Fast engraving speed with solid build quality; highly reliable!

Katarina White (verified owner) –

**Performance & User Experience Review:**

The xTool D1 Pro 10W laser excels on wood (maple plywood engraved at 1000mm/min, 0.08mm precision) and leather (detailed coasters with minimal charring using air assist). However, 3mm acrylic required multiple passes, risking warping. Setup was intuitive, but the camera alignment needed recalibration. XCS software’s drag-and-drop workflow streamlined complex designs, though lag occurred with 4000x4000px files. Rotary tool integration enabled flawless tumbler engravings. Ideal for small businesses needing versatile, high-detail output, but acrylic handling and software optimization need refinement. ROI justifies cost for frequent users.

Helena Gonzalez (verified owner) –

The laser engraver excels in performance across various materials, delivering crisp engravings on wood, acrylic, and leather. Its precision is remarkable for intricate designs, such as a detailed family crest on oakwood. However, the speed varies depending on material thickness; thicker acrylic requires longer processing times. The user-friendly interface streamlines operations, though advanced users may seek more customization options. It shines in artistic applications like personalized jewelry tags but struggles with harder materials like metal without additional power adjustments. Overall, it’s a versatile tool for small-scale projects, offering good value for hobbyists and light commercial use.

Pedro Mueller (verified owner) –

The laser engraver excels in versatility, delivering crisp results on wood, acrylic, and leather. Its precision is evident in detailed engravings like intricate patterns on oakwood coasters and smooth, clean cuts on acrylic signs. While it handles medium-speed projects efficiently, thicker materials or highly detailed designs require careful adjustment. The 10W laser offers adequate power for most applications, but a larger workspace would enhance productivity for larger-scale projects. Overall, it balances performance and usability effectively for both hobbyists and small businesses.

Lars Yang (verified owner) –

**Laser Engraver Review for Architectural Model Making**

**1. Project Experience:**

– **Project Focus:** Utilized the laser engraver in creating detailed scale models for a university campus expansion project. The tool was instrumental in producing precise urban layouts and building structures.

– **Materials Used:** Primarily MDF and acrylic, chosen for their compatibility with laser engraving and durability in architectural models.

– **Challenges and Solutions:** Encountered warping issues with MDF due to heat from the laser. This was mitigated by adjusting cutting speeds and using thinner layers, which reduced thermal stress and maintained structural integrity.

– **Results:** The models received high praise for their detail and accuracy, enhancing client presentations and understanding of the project.

**2. Technical Performance:**

– **Precision and Power:** The engraver’s adjustable power settings allowed fine engravings without excessive burning, crucial for maintaining model aesthetics. It handled intricate designs effortlessly, even with complex geometries.

– **Software Integration:** The software seamlessly integrated with CAD files, enabling precise vector cutting and raster engraving. A standout feature was its ability to process multi-layered engravings, which saved time by completing detailed work in fewer steps.

**3. Business Impact:**

– **Workflow Efficiency:** The laser engraver significantly reduced production time, allowing the studio to take on more projects without compromising quality.

– **Client Feedback:** Clients appreciated the high precision and detail, leading to repeat business and referrals.

– **Cost-Effectiveness:** Reduced material waste and minimized errors from manual methods led to cost savings. The tool justified its investment through increased productivity and capacity.

**Conclusion:**

The laser engraver has been a transformative tool for our architectural model making process. It enhanced project outcomes, improved efficiency, and contributed positively to business growth by delivering high-quality results that meet client expectations.

Young Davis –

“Excellent laser engraver! Superb engraving precision and detail. User-friendly software and smooth operation. Fast, efficient, and reliably well-built. Highly recommend!”

Juan Smith –

“Exceptional laser engraver! Superb engraving precision and detail. User-friendly software and intuitive controls. Fast, efficient, and built to last. Highly recommend!”

Juan Mueller –

Exceptional laser engraver! Outstanding engraving quality and precision. User-friendly software and intuitive controls. Fast carving speed boosts efficiency. Solid build quality ensures reliability. Highly recommended!

Hans Martin –

“Exceptional laser engraver! Precise, detailed cuts with user-friendly software. Fast, efficient, and reliably well-built. Highly recommend!”

Ming Nakamura (verified owner) –

I’m thrilled with the LaserHawk LX1 laser engraver—it’s been a lifesaver for my custom gift business! Its versatility has allowed me to tackle various projects, from intricate wood engravings to precise metalwork, making it an indispensable tool. It’s a must-have for any small business looking to deliver top-notch craftsmanship efficiently.

Hiroshi Bernard –

五星好评: This laser engraver delivers exceptional precision and detail in every project. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Sturdy build, highly reliable.