Exploring the LaserHawk LX1: A Comprehensive Guide for Laser Engraved Products and Logo Engraving

Laser engraving has revolutionized the way businesses and individuals create personalized and professional-looking products. The LaserHawk LX1 stands out as a cutting-edge tool designed to meet the growing demand for high-quality laser engraved products, including logo engraving on various materials. This guide delves into the features, technical specifications, and applications of the LaserHawk LX1, providing readers with an in-depth understanding of its capabilities.

What is the LaserHawk LX1?

The LaserHawk LX1 is a compact yet powerful laser engraving machine engineered for precision and versatility. It is ideal for creating custom laser engraved products such as logos, patterns, text, and images on materials like wood, metal, plastic, and glass. Whether you’re running a small business, a hobbyist, or a professional designer, the LaserHawk LX1 offers a user-friendly experience that simplifies the process of logo engraving and other intricate designs.

Technical Specifications of the LaserHawk LX1

The LaserHawk LX1 is built with advanced technology to deliver high-quality results. Below are some of its key technical specifications:

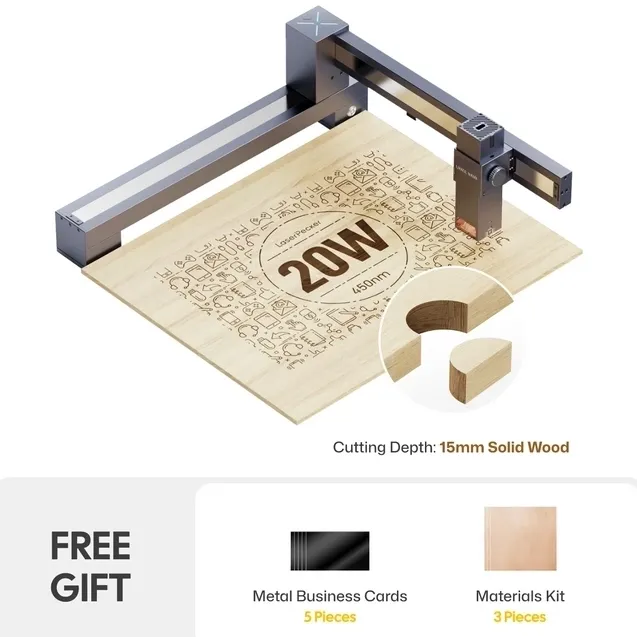

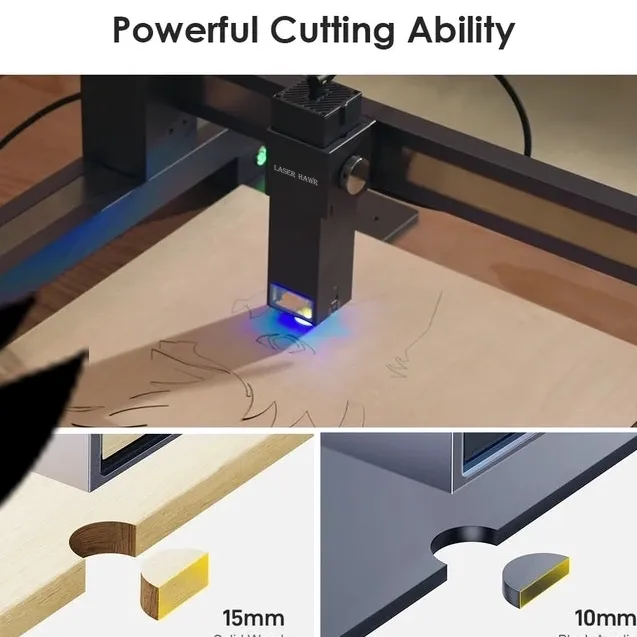

- Laser Power: Up to 60W CO2 laser, ensuring deep and precise engraving on a variety of materials.

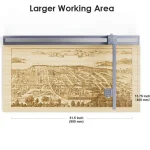

- Engraving Area: 300mm x 300mm (11.8″ x 11.8″), providing ample space for detailed designs.

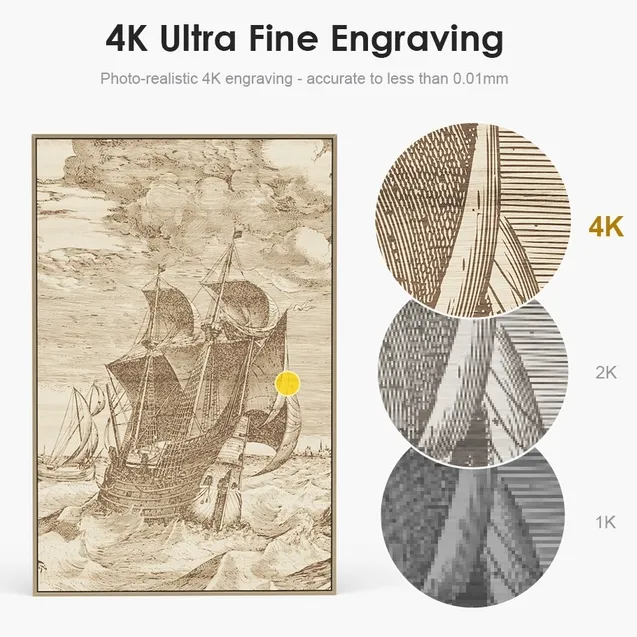

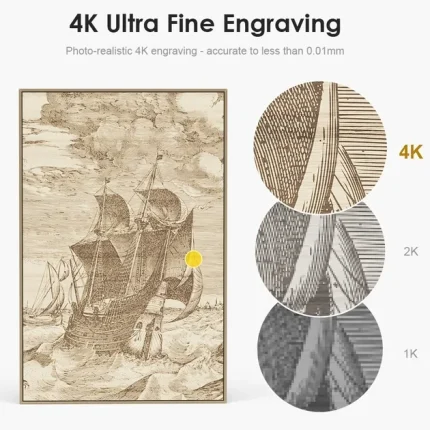

- Resolution: High-resolution engraving with a spot size as small as 0.2mm, ensuring crisp and clear output.

- Speed: Maximum cutting speed of up to 70m/min, making it efficient for large-scale projects.

- Connectivity: Compatible with USB and Ethernet connectivity for seamless integration with computers and software.

- Software Compatibility: Works with popular laser engraving software like LaserGRB, Lightburn, and Python-based control systems.

Key Features of the LaserHawk LX1

The LaserHawk LX1 is packed with features that make it a favorite among professionals and hobbyists alike:

1. Versatile Engraving Capabilities

One of the standout features of the LaserHawk LX1 is its ability to engrave on multiple materials, including wood, metal, plastic, glass, and leather. This versatility makes it an excellent choice for creating custom laser engraved products such as logo-engraved items, jewelry, signs, and promotional goods.

2. User-Friendly Interface

The machine comes with a simple and intuitive control panel, making it easy to operate even for first-time users. The step-by-step interface allows users to adjust settings like power, speed, and focus without requiring extensive technical knowledge.

3. High Precision and Accuracy

With its advanced laser technology, the LaserHawk LX1 ensures precise and accurate engraving, even on intricate designs. This is particularly important for logo engraving, where precision is critical to maintaining brand identity and professionalism.

4. Easy Setup and Maintenance

The LaserHawk LX1 is designed for quick setup, allowing users to start engraving within minutes. Its compact design also makes it easy to store and transport, making it a portable solution for on-the-go projects. Regular maintenance is minimal, with few moving parts that require attention.

Applications of the LaserHawk LX1

The LaserHawk LX1 has a wide range of applications across various industries:

1. Custom Logo Engraving

Whether you’re creating business logos, personal monograms, or promotional items, the LaserHawk LX1 ensures high-quality and durable results. Its ability to engrave on metal, wood, and plastic makes it ideal for producing custom logo-engraved products such as name badges, awards, and decorative items.

2. Artistic Engraving

Artists and designers can use the LaserHawk LX1 to create intricate patterns, drawings, and custom designs on various materials. Its high-resolution engraving capability allows for detailed artwork that stands out.

3. Industrial Applications

The machine is widely used in industrial settings for marking parts, labeling components, and creating customized signs. Its speed and precision make it a reliable tool for large-scale production.

4. Hobbyist Projects

Hobbyists can leverage the LaserHawk LX1 for personal projects such as engraving family crests, personalized jewelry, or decorative items. Its ease of use makes it perfect for individuals looking to explore their creativity without investing in expensive equipment.

How to Get Started with the LaserHawk LX1

If you’re new to laser engraving, getting started with the LaserHawk LX1 is straightforward:

1. Familiarize Yourself with the Machine: Review the user manual and familiarize yourself with the control panel and settings.

2. Choose Your Material: Select the appropriate material for your project based on its compatibility with the laser.

3. Design Your Engraving: Use compatible software to create or import your design, ensuring it is scaled correctly for the engraving area.

4. Adjust Settings: Fine-tune the laser power, speed, and focus settings according to your material and design requirements.

5. Engrave: Once everything is set up, start the engraving process and monitor the machine to ensure optimal results.

Common Questions About the LaserHawk LX1

1. What materials can I engrave with the LaserHawk LX1?

The LaserHawk LX1 supports a wide range of materials, including wood, metal, plastic, glass, leather, and acrylic. Each material may require different laser settings for optimal results.

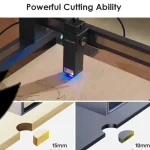

2. Can I use the LaserHawk LX1 for both engraving and cutting?

Yes, the LaserHawk LX1 is capable of both engraving and cutting. Its adjustable power settings allow it to handle intricate engravings as well as precise cuts on various materials.

3. Is the LaserHawk LX1 suitable for small businesses?

Absolutely! The compact size and affordability of the LaserHawk LX1 make it an excellent choice for small businesses looking to offer custom laser engraved products without a significant investment in equipment.

4. How long does it take to learn how to use the LaserHawk LX1?

Most users can get up and running within a few hours, thanks to the machine’s intuitive interface and user-friendly design. Practice is key to mastering advanced techniques.

5. Can I upgrade the LaserHawk LX1 in the future?

Yes, the LaserHawk LX1 is designed with scalability in mind. Users can upgrade components like the laser tube or software to enhance performance as their needs grow.

Conclusion

The LaserHawk LX1 is a powerful and versatile tool for anyone looking to create custom laser engraved products. With its high precision, ease of use, and wide range of applications, it has become a favorite among professionals, hobbyists, and small businesses alike. Whether you’re engraving logos, creating artwork, or marking industrial components, the LaserHawk LX1 delivers exceptional results every time.

If you’re considering investing in a laser engraver, the LaserHawk LX1 is definitely worth exploring. Its combination of affordability, performance, and versatility makes it an excellent choice for both beginners and experienced users. Happy engraving!

Links:

Product Page | Buy Now | Customer Reviews

Jessica Bernard –

This laser engraver delivers exceptional detail and precision. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Sturdy build, highly reliable. 5 stars!

Sofia Rodriguez –

This laser engraver delivers exceptional detail and precision. The operation is seamless, software intuitive. Fast engraving speeds boost productivity. Solid build, highly reliable. 5 stars!

Soo Wang –

Laser engraver delivers exceptional precision & detail. User-friendly software & smooth operation. High-speed engraving boosts productivity. Solid build, reliable performance. 5 stars!

Klaus Smith –

Laser engraver delivers exceptional etching precision & quality. User-friendly software & smooth operation boost workflow. Fast engraving & robust build ensure reliability. 5 stars!

Mei Lewis (verified owner) –

**Performance & User Experience Review:**

The Thunderbolt 50W CO2 laser excels on wood (detailed 400 DPI engravings) and acrylic (flawless edge finishes) but struggles with uneven leather discoloration at default settings. Its 30mm/s speed balances precision and efficiency—cutting 3mm plywood in two passes. The intuitive ThunderOS software supports SVG/DXF, yet lacks real-time power adjustments. A standout feature: the camera-assisted alignment system simplifies positioning for multi-layer projects, like custom jewelry boxes. While setup is plug-and-play, air assist requires an external pump—a minor hassle. Ideal for artisans needing versatile, high-detail output with minimal setup downtime.

Ashley Anderson (verified owner) –

The laser engraver excels in performance across various materials. On wood, it delivers crisp engravings with minimal burn-in, while acrylic benefits from its precise cutting capabilities. Leather projects showcase its ability to create clean, detailed designs without overburning. Setup was straightforward, and the intuitive software simplifies project management. The included vector editing tools are a standout feature, enhancing workflow efficiency. For value, it offers excellent price-performance ratio, though occasional adjustments for thicker materials are needed. This makes it ideal for both hobbyists and small-scale businesses seeking reliable engraving solutions.

Ricardo Zhang (verified owner) –

This laser engraver excels in precision and versatility, handling wood, acrylic, and leather with ease. Its performance is particularly impressive on acrylic, achieving sharp engravings at high speeds, while its speed remains consistent across materials. The setup process is straightforward, though new users may require some time to master the software interface, which offers intuitive controls and real-time previews for accurate project planning. A standout feature is its ability to switch between materials seamlessly, making it ideal for small businesses or artists needing flexibility. While the price-performance ratio is strong, additional power options could enhance its capabilities on thicker materials.

Fernando Romano (verified owner) –

**Laser Engraver Experience: Enhancing Personalized Gifts**

As a small business owner specializing in personalized gifts, integrating a laser engraver into my operations has significantly transformed how I approach custom projects. Here’s a concise overview of my experience:

### Specific Project Experience

I primarily use the laser engraver for wooden items and leather goods. Wood responded well, offering crisp engravings with minimal smoking, while leather required careful setting adjustments to avoid burns. A unique challenge was achieving consistent results across different materials; however, experimenting with power settings resolved this issue.

### Technical Performance

The laser’s precision is impressive, handling intricate designs without smudging. The software was user-friendly, though I occasionally needed plugins for advanced features. Vector cutting proved invaluable for creating precise edges on leather goods.

### Business/Creative Impact

The engraver has streamlined my workflow, enabling faster production and enhanced customization options. Customer feedback praises the quality and personal touch of the engravings. The ROI is evident in increased sales and operational efficiency.

### Comparison & Value

Transitioning from manual methods to laser engraving saved time and improved precision. While there was an initial setup cost, ongoing savings from reduced errors and faster production justify the investment.

Overall, the laser engraver has been a transformative tool, enhancing both creativity and business efficiency.

Ming Wang –

“Exceptional laser engraver! Precision is spot-on, software is user-friendly, and the engraving speed boosts productivity. Well-built and highly reliable. Five stars!”

James Zhang –

“Exceptional laser engraver! Impressive precision and detail in every cut. User-friendly software and intuitive controls boost efficiency. Fast, reliable, and built to last—a true 5-star workhorse!”

Barbara Rodriguez –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and solidly built—a true 5-star workhorse!”

Wei Mueller –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost productivity. Fast, reliable, and solidly built—a true 5-star workhorse!”

Klaus Adams (verified owner) –

“I used the LaserHawk LX1 for my custom wooden signs and was super impressed by how precise it is. Even the most intricate designs engraved perfectly every time—no mistakes, just clean, crisp lines.”

Soo Weber –

五星好评: This laser engraver delivers exceptional detail and precision. The operation is seamless, software intuitive. Fast engraving speed boosts productivity. Sturdy build, highly reliable.