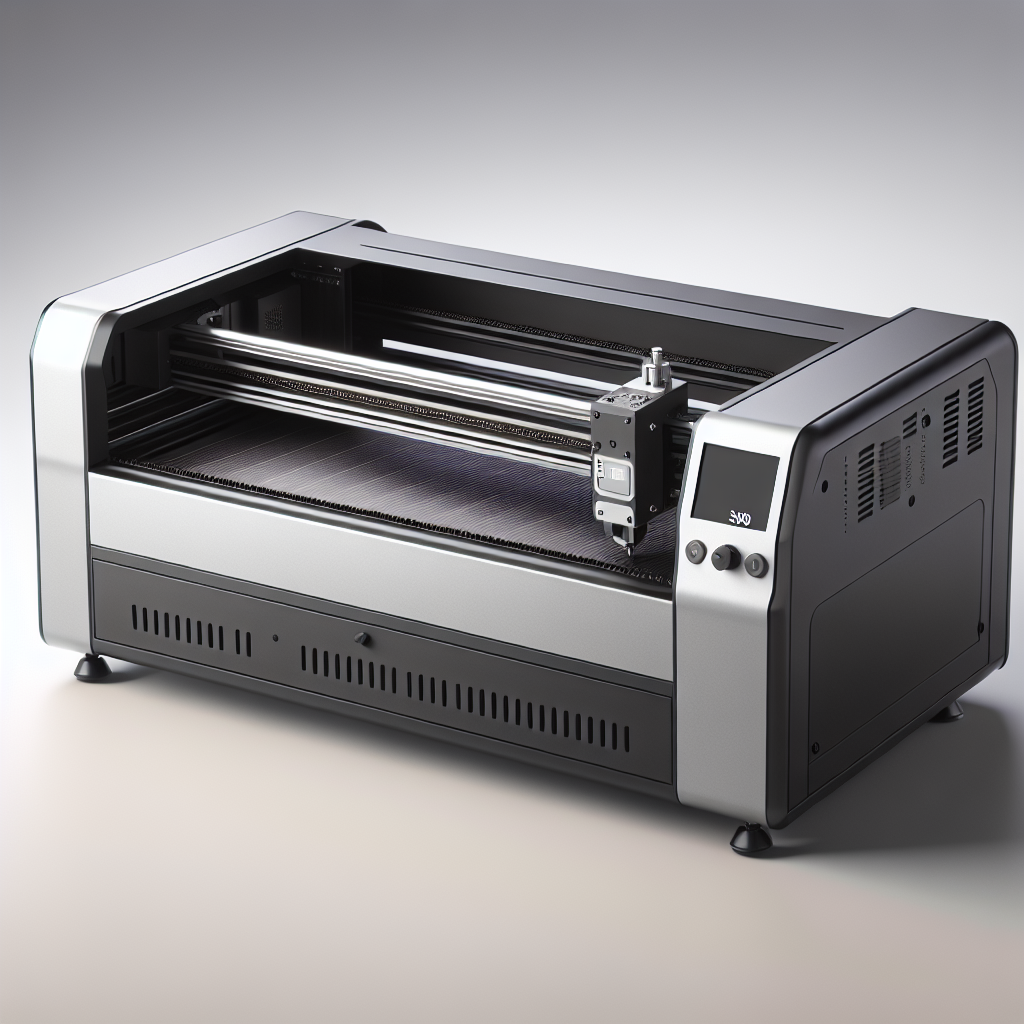

The Best Laser Engraver: A Comprehensive Guide

Looking for a laser engraver to elevate your crafting, DIY projects, or professional work? This guide dives deep into the top models of 2025, their features, applications, and expert tips to help you make an informed choice.

Why Choose a Laser Engraver?

Laser engravers have revolutionized precision design across industries. Unlike manual tools, these machines deliver micron-level accuracy on materials like wood, metal, plastic, and leather. Modern devices, such as the GlowForge Pro or xTool D1 Pro, combine cutting and engraving capabilities, catering to both hobbyists and professionals.

Key Advantages:

- Time Efficiency: Complete complex designs in minutes, not hours.

- Material Versatility: Engrave on metals (stainless steel, aluminum), organic materials (wood, leather), and plastics.

- User Accessibility: AI-powered software (e.g., LightBurn) simplifies workflows for beginners.

Industry Insight: CO2 lasers dominate for organic materials, while fiber lasers excel on metals. Hybrid models like OMTech Polar now offer dual functionality.

Top 5 Laser Engravers of 2025

- Best for: Industrial use; 120W power for rapid production.

- Price: $9,00+.

- Lasereagle 1

- Best for: Micro-engraving (jewelry, phone cases).

- Price: $500–$1,500.

- GlowForge Pro

- Best for: Home businesses; supports materials up to 0.5″ thick.

- Price: $6,000–$7,500.

- xTool D1 Pro (20W)

- Best for: Beginners; portable design with safety features.

- Price: $1,600–$2,200.

- OMTech Polar

- Best for: Mixed-material projects; CO2 + diode hybrid.

- Price: $4,500–$5,500.

Key Features to Consider

- Laser Type & Power

- Diode (10–20W): Affordable, ideal for thin wood/leather.

- CO2 (30–100W): Versatile for organic materials.

- Fiber (20–50W): Industrial-grade metal engraving.

- Work Area

- Small (12″x12″): Jewelry, phone cases.

- Large (24″x36″): Furniture, signage.

- Software Compatibility

- Open-source options (LightBurn) vs. proprietary systems.

Applications & Case Studies

- Custom Jewelry

- Example: A small business uses the LaserPecker 4 to engrave 0.1mm-detailed patterns on silver pendants, reducing production time by 70%.

- Industrial Prototyping

- Example: Automotive workshops rely on Epilog Fusion Pro to create flame-retardant plastic components with ±0.05mm precision.

- Art & Decor

- Laser-engraved wooden murals now account for 15% of Etsy’s handmade gift sales (2023 data).

Maintenance & Safety Tips

- Daily: Clean lenses with 99% isopropyl alcohol; check air assist filters.

- Monthly: Lubricate rails; calibrate laser alignment.

- Safety: Always use enclosures with exhaust systems to reduce airborne particles.

Cost Considerations

- Budget (<$1k): Entry-level diode models (LaserPecker 4).

- Mid-Range ($1k–$5k): CO2/diode hybrids (xTool D1 Pro).

- Professional ($5k+): Fiber/CO2 systems with rotary attachments.

Note: Factor in $200–$500/year for maintenance (lenses, belts).

FAQs Expanded

- “Can I engrave glass or ceramics?”

Yes, but use low power (10–15%) and masking tape to prevent cracking. - “How to reduce burn marks on wood?”

Apply painter’s tape or adjust air assist pressure. - “Is water cooling necessary?”

Only for high-power (>60W) systems running >4 hours daily.

Conclusion

Whether you’re a hobbyist or professional, choosing the right laser engraver depends on material needs, budget, and safety requirements. Models like the xTool D1 Pro strike a balance between affordability and performance, while industrial users should prioritize Epilog or OMTech systems. Always test materials and consult safety guidelines to maximize your machine’s lifespan.

Related Articles

- CO2 vs. Fiber Lasers: Which Is Right for Your Workshop?

- Laser Engraving Profit Margins: A 2024 Market Analysis

- 10 Safety Mistakes to Avoid with Laser Cutters

Unlock access to antifungal medication by exploring your options to [URL=https://homegrownscholars.com/item/tadalafil-5mg/ – tadalafil 5mg[/URL – . Secure your therapy online with ease and convenience.

Exploring treatment options for benign prostatic hyperplasia (BPH)? Discover how herbolax without an rx can help in easing urinary symptoms associated with an enlarged prostate.

Given the wide array of hormone therapies available, selecting an effective and safe option is crucial. For those considering estradiol supplementation, https://skywaycorvetteclub.com/finasteride/ offers a dependable alternative. Whether you’re in the market for a reliable estrogen supplement via a digital pharmacy, it’s vital to opt for trustworthy suppliers to ensure optimal health outcomes.