The Evolution and Applications of Laser Engraving Machines for Creating Laser Engraved QR Codes

In today’s fast-paced industrial and creative landscapes, laser engraved QR codes have emerged as a game-changing solution for businesses and hobbyists alike. These intricate, scannable codes are not only durable but also highly customizable, making them ideal for applications ranging from product authentication to artistic designs. At the heart of this innovation lies advanced laser engraving machines, which combine precision, speed, and versatility to meet modern demands. This article explores how these machines work, their benefits, and why they are essential for producing laser engraved QR codes.

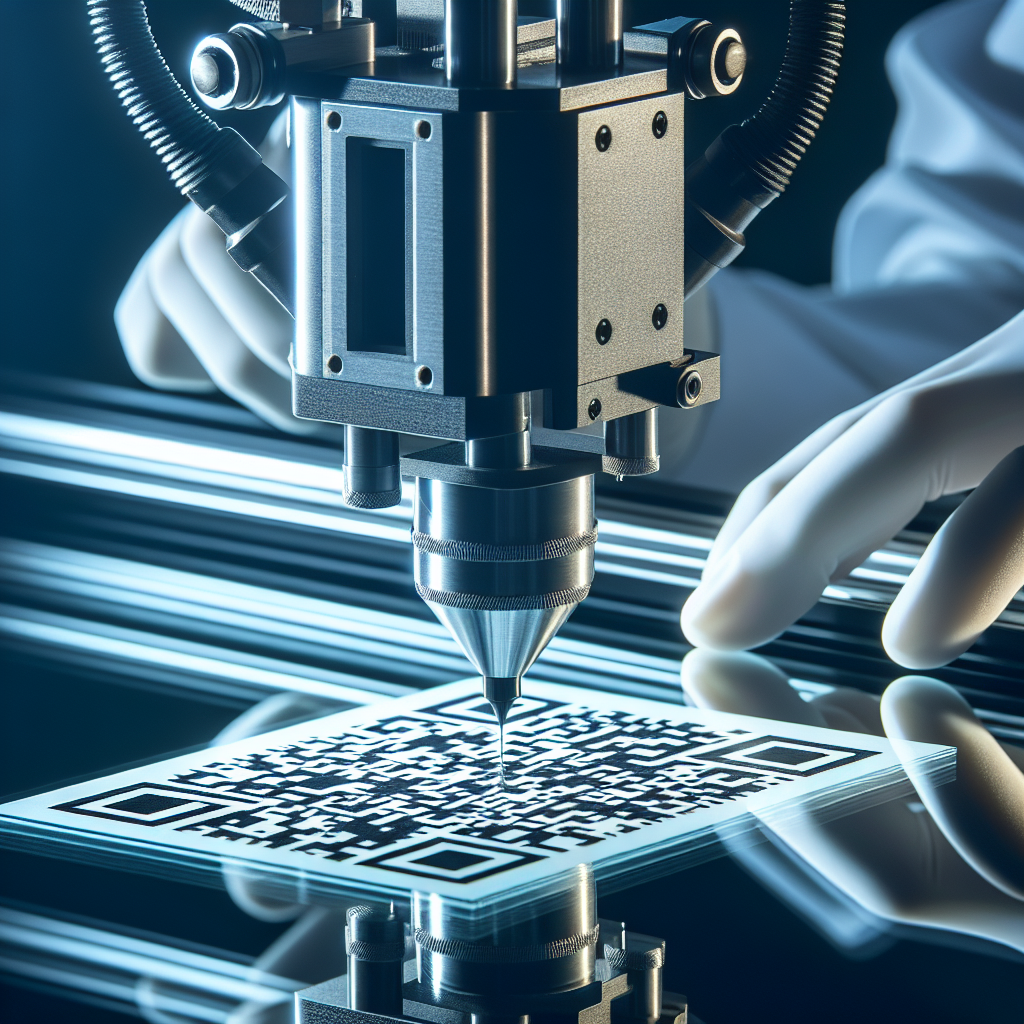

How Do Laser Engraving Machines Work?

Laser engraving machines utilize focused laser beams to etch designs onto materials like metal, wood, plastic, and glass. The process involves three key steps:

- Design Input: A digital file (e.g., a QR code) is uploaded to the machine’s software.

- Laser Focusing: The laser beam is calibrated to the material’s thickness and hardness.

- Engraving: The laser vaporizes or oxidizes the material’s surface, creating permanent marks.

For laser engraved QR codes, this precision ensures that even the tiniest modules within the code remain legible, which is critical for reliable scanning. Why is this important? A poorly engraved QR code could lead to scanning failures, compromising functionality in industrial or retail settings.

Advantages of Laser Engraved QR Codes

Laser engraved QR codes offer unmatched durability compared to printed labels or stickers. They resist fading, abrasion, and exposure to harsh chemicals, making them suitable for:

- Industrial part tracking

- Medical device identification

- Outdoor equipment labeling

Moreover, laser engraving machines enable customization at scale. Whether you need 10 or 10,000 codes, the process remains consistent and efficient. How does this impact businesses? It reduces long-term costs by eliminating the need for label replacements and minimizing errors in automated systems.

Choosing the Right Laser Engraving Machine

Not all laser engraving machines are created equal. Key factors to consider include:

- Laser Power: Higher wattage (e.g., 50W–100W) handles metals and thick materials.

- Software Compatibility: Ensure the machine supports QR code generation tools.

- Speed and Precision: Look for micron-level accuracy for tiny QR modules.

For instance, the laser engraved QR codes used in aerospace components require machines with fiber lasers, which excel on metals. Conversely, CO2 lasers are better suited for organic materials like wood or leather.

Industries Revolutionized by Laser Engraved QR Codes

The adoption of laser engraved QR codes spans multiple sectors:

- Manufacturing: Track parts through supply chains with scannable codes.

- Healthcare: Ensure traceability of surgical instruments.

- Retail: Enhance customer engagement with engraved promotional codes.

What challenges do these industries face? Traditional labeling methods often fail under extreme conditions, whereas laser-engraved marks withstand high temperatures, solvents, and physical wear.

Common Questions About Laser Engraving Machines and QR Codes

Q: Can laser engraving machines handle colored QR codes?

A: While lasers typically create monochromatic marks, some materials (like anodized aluminum) produce contrast variations for better readability.

Q: How small can a laser engraved QR code be?

A: This depends on the machine’s resolution. High-end systems can engrave codes as small as 2×2 mm while maintaining scannability.

Q: Are laser engraved QR codes secure against tampering?

A: Yes. Unlike stickers, these codes cannot be peeled off or altered without visible damage, making them ideal for anti-counterfeiting.

Future Trends in Laser Engraving Technology

As demand for laser engraved QR codes grows, manufacturers are pushing boundaries with innovations like:

- AI-Driven Optimization: Machines that auto-adjust settings based on material scans.

- Ultrafast Lasers: Reduce engraving time by 50% without sacrificing quality.

- 3D Engraving: Create textured QR codes for tactile applications.

What does this mean for small businesses? Lower-cost, user-friendly machines are democratizing access to this technology, enabling startups to compete with larger enterprises.

Conclusion: Why Invest in Laser Engraving Machines?

From enhancing supply chain transparency to enabling creative branding, laser engraved QR codes are a cornerstone of modern manufacturing and design. Laser engraving machines provide the precision, durability, and scalability required to meet these needs. As industries continue to prioritize efficiency and security, investing in the right laser technology is no longer optional—it’s essential.

Ready to explore how laser engraving can transform your business? Evaluate your material requirements, production volume, and budget to choose a machine that unlocks the full potential of laser engraved QR codes.