The Ultimate Guide to Diode Laser Cutter and Engraver

Laser technology has revolutionized the way we approach crafting, manufacturing, and art. Among the many innovations in this field, the diode laser cutter and engraver stands out as a versatile tool that combines precision, efficiency, and creativity. Whether you’re a hobbyist, an artist, or a small business owner, this device offers endless possibilities for cutting and engraving various materials with ease. In this comprehensive guide, we’ll explore what makes the diode laser cutter and engraver a must-have tool for your workshop or studio.

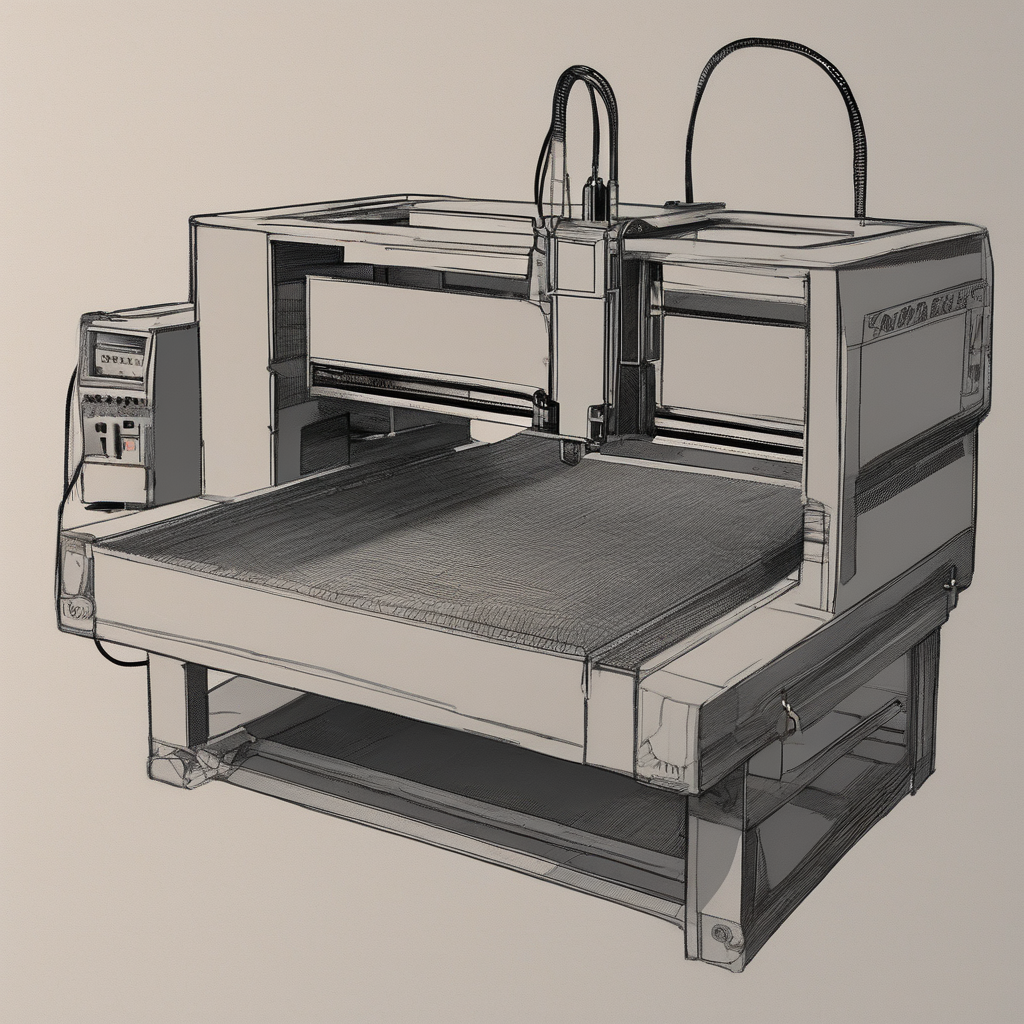

What is a Diode Laser Cutter and Engraver?

A diode laser cutter and engraver is a compact, high-precision device designed to cut and engrave materials like wood, acrylic, leather, fabric, and more. Unlike traditional lasers, which use gas or crystals, this tool relies on semiconductor diodes to generate the laser beam. This makes it lightweight, energy-efficient, and ideal for small-scale projects. The machine typically comes with a user-friendly interface, allowing you to control the laser’s power, speed, and focus settings to achieve perfect results every time.

If you’re wondering, “How does a diode laser cutter work?” the answer lies in its ability to concentrate light energy into a narrow beam. This focused beam heats the material, causing it to vaporize or char, creating precise cuts or engravings. The process is fast, clean, and requires minimal setup, making it an excellent choice for both beginners and experienced users.

Key Features of a Diode Laser Cutter and Engraver

The diode laser cutter and engraver boasts several features that set it apart from other cutting tools:

- High Precision: The laser beam is highly focused, allowing for intricate designs and precise cuts.

- Wide Range of Applications: Suitable for engraving on wood, acrylic, leather, fabric, and other materials.

- User-Friendly Design: Intuitive controls and easy setup make it accessible to everyone.

- Energy Efficiency: Uses less power compared to traditional laser cutters, reducing operating costs.

- Compact Size: Portable and space-saving, perfect for small workshops or home use.

These features make it a versatile tool for hobbyists, crafters, and small businesses looking to add a professional touch to their projects.

Applications of a Diode Laser Cutter and Engraver

The diode laser cutter and engraver is incredibly versatile and can be used in numerous applications. Here are some popular uses:

- Woodworking: Create custom furniture, decorative items, or personalized wood signs.

- Crafts: Engrave intricate designs on leather, fabric, or paper for unique gifts and accessories.

- Signage: Produce high-quality signs, plaques, and nameplates with precise engravings.

- Fabric Cutting: Perfect for creating patterns, logos, or decorative elements on textiles.

- Jewelry Making: Engrave delicate designs on metal or gemstones for custom jewelry pieces.

With its wide range of applications, the is a valuable tool for anyone looking to bring their creative ideas to life.

Advantages Over Traditional Laser Cutters

While traditional laser cutters have been the go-to choice for many years, the diode laser cutter and engraver offers several advantages:

- Cost-Effective: Lower power consumption and fewer maintenance requirements reduce operating costs.

- Easier Setup: No need for complex alignment or gas refills, making it simpler to get started.

- Faster Processing: The laser beam delivers quick cuts and engravings, saving time on projects.

- Safety: Produces less heat compared to traditional lasers, reducing the risk of burns or fires.

These benefits make the an excellent alternative for those seeking a more affordable and user-friendly option.

Maintenance and Safety Tips

To ensure your diode laser cutter and engraver performs optimally, proper maintenance is essential. Here are some tips:

- Clean Regularly: Dust and debris can accumulate on the machine, so clean it regularly to maintain performance.

- Check Alignment: Periodically verify the laser alignment to ensure accurate cuts and engravings.

- Use Safety Gear: Always wear protective eyewear and gloves when operating the machine.

- Follow Instructions: Read the user manual carefully and follow all safety guidelines provided by the manufacturer.

By following these tips, you can extend the lifespan of your tool and ensure safe operation.

Frequently Asked Questions (FAQs)

Q: Can a diode laser cutter engrave metal?

A: While it’s possible to engrave metal with a diode laser cutter, the results may not be as deep or detailed compared to other materials like wood or acrylic. For heavy-duty metal engraving, a more powerful laser is recommended.

Q: Is a diode laser cutter suitable for beginners?

A: Absolutely! Its user-friendly design and intuitive controls make it an excellent choice for newcomers to laser cutting and engraving.

Q: How long does the laser diode last?

A: The lifespan of a laser diode typically ranges from 10,000 to 25,000 hours, depending on usage and maintenance. Regular cleaning and proper handling can extend its longevity.

Conclusion

The diode laser cutter and engraver is a game-changer for anyone looking to explore the world of laser cutting and engraving. With its precision, versatility, and ease of use, it’s no wonder this tool has become a favorite among hobbyists, artists, and professionals alike. Whether you’re creating custom designs, crafting unique gifts, or running a small business, investing in a can open up a world of possibilities for your projects.

If you’re ready to take your creativity to the next level, why not give it a try? Your next project is just a few clicks away!