The Ultimate Guide to Fiber Laser Engravers: Precision, Speed, and Versatility

Fiber laser engravers have revolutionized the world of precision cutting and engraving. These advanced machines are setting new standards for industries ranging from woodworking and metal fabrication to jewelry making and sign. If you’re looking for a tool that combines speed, accuracy, and versatility, then a fiber laser engraver might be exactly what you need. In this comprehensive guide, we’ll explore everything you need to know about fiber laser engravers, their applications, advantages, and how they can transform your projects. Whether you’re a hobbyist or a professional, this article will help you understand the power of fiber laser technology.

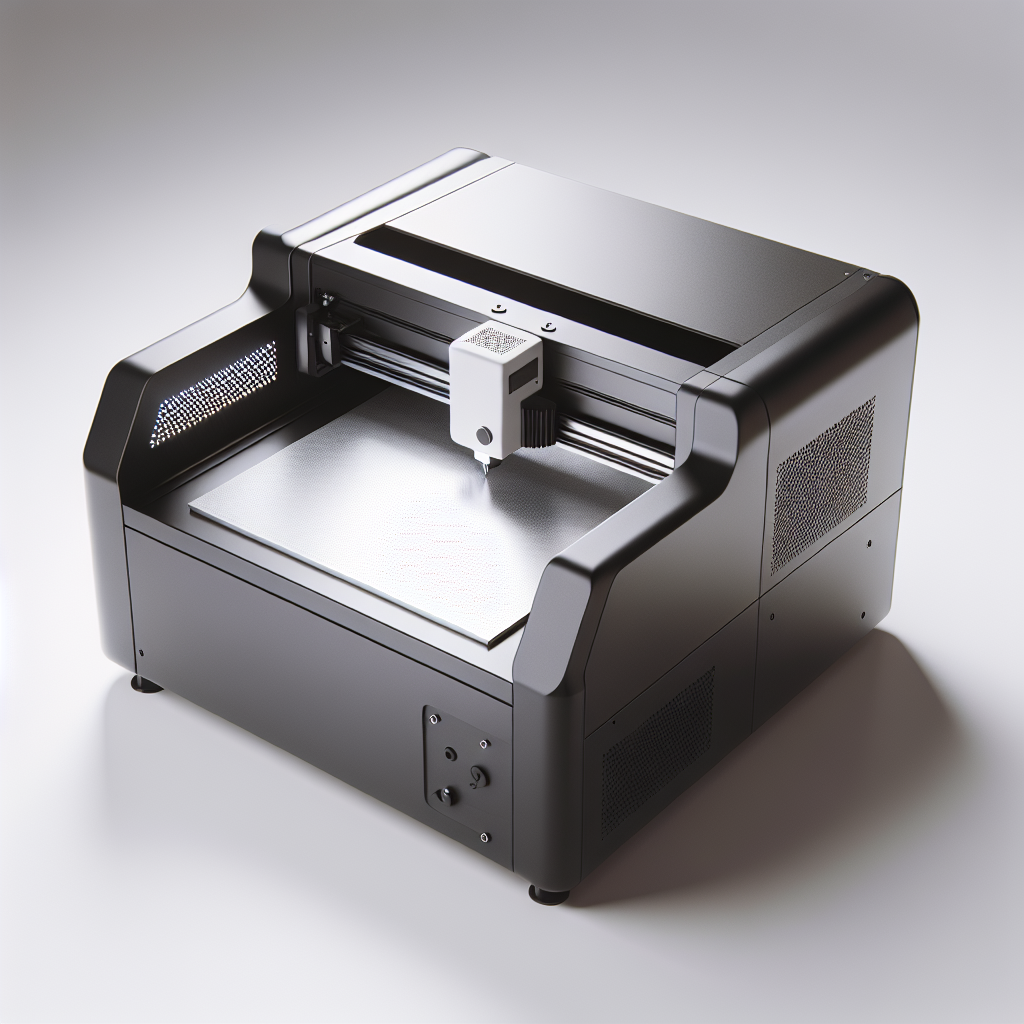

What is a Fiber Laser Engraver?

A fiber laser engraver is a cutting-edge machine that uses fiber laser technology to etch intricate designs onto various materials. Unlike traditional engraving methods, which often rely on mechanical tools or less precise lasers, fiber laser engravers offer unparalleled precision and speed. The machine works by directing a highly focused beam of light at the material, vaporizing or melting it to create detailed patterns. This process is not only faster but also produces cleaner results compared to traditional methods.

Fiber laser engravers are particularly popular for their ability to work on a wide range of materials, including wood, metal, plastic, and even glass. They are ideal for creating custom designs, logos, and text that require a high level of detail. Whether you’re crafting personalized jewelry or producing large-scale signs, these machines can handle it all.

Applications of Fiber Laser Engravers

Fiber laser engravers have a vast array of applications across different industries. Some of the most common uses include:

- Woodworking: Creating intricate designs, inlays, and furniture decorations.

- Metal fabrication: Engraving logos, serial numbers, and complex patterns on metal surfaces.

- Jewelry making: Etching delicate details on precious metals and gemstones.

- Sign: Producing high-quality signs with customized text and graphics.

- Custom branding: Adding logos and trademarks to products for marketing purposes.

The versatility of fiber laser engravers makes them a must-have tool for anyone looking to add precision and professionalism to their projects. Whether you’re working on small-scale crafts or large industrial applications, these machines deliver exceptional results every time.

Advantages of Using a Fiber Laser Engraver

There are numerous reasons why fiber laser engravers have become so popular in recent years. Some of the key advantages include:

- High precision: The focused laser beam ensures that even the most intricate designs are engraved with pinpoint accuracy.

- Speed: Fiber lasers operate at a much faster rate than traditional engraving methods, saving time and increasing productivity.

- Versatility: They can work on a wide range of materials, making them suitable for diverse applications.

- Durability: Fiber lasers have a long lifespan and require minimal maintenance compared to other laser technologies.

- Ease of use: Modern fiber laser engravers come with user-friendly interfaces and software, making them accessible even for beginners.

These advantages make fiber laser engravers an ideal choice for both small-scale hobbyists and large-scale industrial operations. Their ability to deliver consistent results time after time has made them a cornerstone of modern manufacturing and craftsmanship.

How Does a Fiber Laser Engraver Work?

To understand how a fiber laser engraver operates, let’s break down the process step by step:

- Laser generation: The machine generates a high-powered laser beam using a fiber optic cable. This beam is highly focused and produces minimal heat distortion.

- Focusing the beam: The laser beam is directed through a series of lenses to ensure it remains tightly focused, allowing for precise cutting or engraving.

- Material interaction: When the laser beam comes into contact with the material, it either melts or vaporizes the surface, creating the desired design.

- Control systems: Advanced control systems ensure that the laser moves accurately across the material, following the programmed design exactly.

This process is not only faster than traditional methods but also produces smoother and more polished results. The lack of physical contact between the machine and the material also means there’s no risk of wear and tear on tools or damage to the workpiece.

Choosing the Right Fiber Laser Engraver

If you’re considering purchasing a fiber laser engraver, it’s essential to evaluate your specific needs before making a decision. Here are some factors to keep in mind:

- Material compatibility: Consider the types of materials you’ll be working with. Some lasers are better suited for certain materials than others.

- Power output: Higher power lasers are capable of cutting through thicker materials but may not be necessary for smaller projects.

- Software compatibility: Look for machines that come with user-friendly software or can integrate with your existing design tools.

- Budget: Fiber laser engravers vary widely in price, so it’s important to find a machine that offers the best value for your needs.

One excellent option to consider is the fiber laser engraver available at [insert link]. This machine is designed to deliver exceptional performance and versatility, making it ideal for both amateur and professional use. Its compact design and user-friendly interface make it easy to set up and operate, while its powerful laser ensures precise and efficient results.

Maintenance and Safety Tips

Like any advanced piece of equipment, fiber laser engravers require proper maintenance to ensure optimal performance and longevity. Here are some tips to keep your machine running smoothly:

- Regular cleaning: Keep the lenses and mirrors clean to prevent dust or debris from affecting the laser beam.

- Lubrication: Follow the manufacturer’s guidelines for lubricating moving parts to ensure smooth operation.

- Software updates: Regularly update the machine’s software to take advantage of new features and improvements.

- Safety precautions: Always wear protective eyewear when operating the machine, and ensure it is properly ventilated to avoid inhaling fumes from the laser process.

By following these simple maintenance tips, you can extend the life of your fiber laser engraver and ensure it continues to deliver high-quality results for years to come.

Fiber Laser Engravers: The Future of Precision Crafting

Fiber laser engravers are more than just tools—they’re a gateway to a new level of creativity and precision. With their ability to handle a wide range of materials, deliver exceptional results, and operate with ease, these machines are revolutionizing the way we approach crafting and manufacturing.

If you’re ready to take your projects to the next level, investing in a fiber laser engraver is an excellent choice. Whether you’re working on small-scale crafts or large industrial applications, this technology will help you achieve the perfect balance of speed, accuracy, and versatility. Explore the possibilities today and discover how fiber laser engravers can transform your work!