The Ultimate Guide to Laser Wood Cutters: Precision and Efficiency

Laser technology has revolutionized various industries, from manufacturing to artistry. Among these innovations, the laser wood cutter stands out as a versatile tool that combines precision with creativity. Whether you’re a hobbyist, an artist, or a professional craftsman, understanding how this machine works and its applications can open up endless possibilities for your projects. In this comprehensive guide, we’ll explore everything you need to know about laser wood cutters, their benefits, uses, and how to choose the right one for your needs.

What is a Laser Wood Cutter?

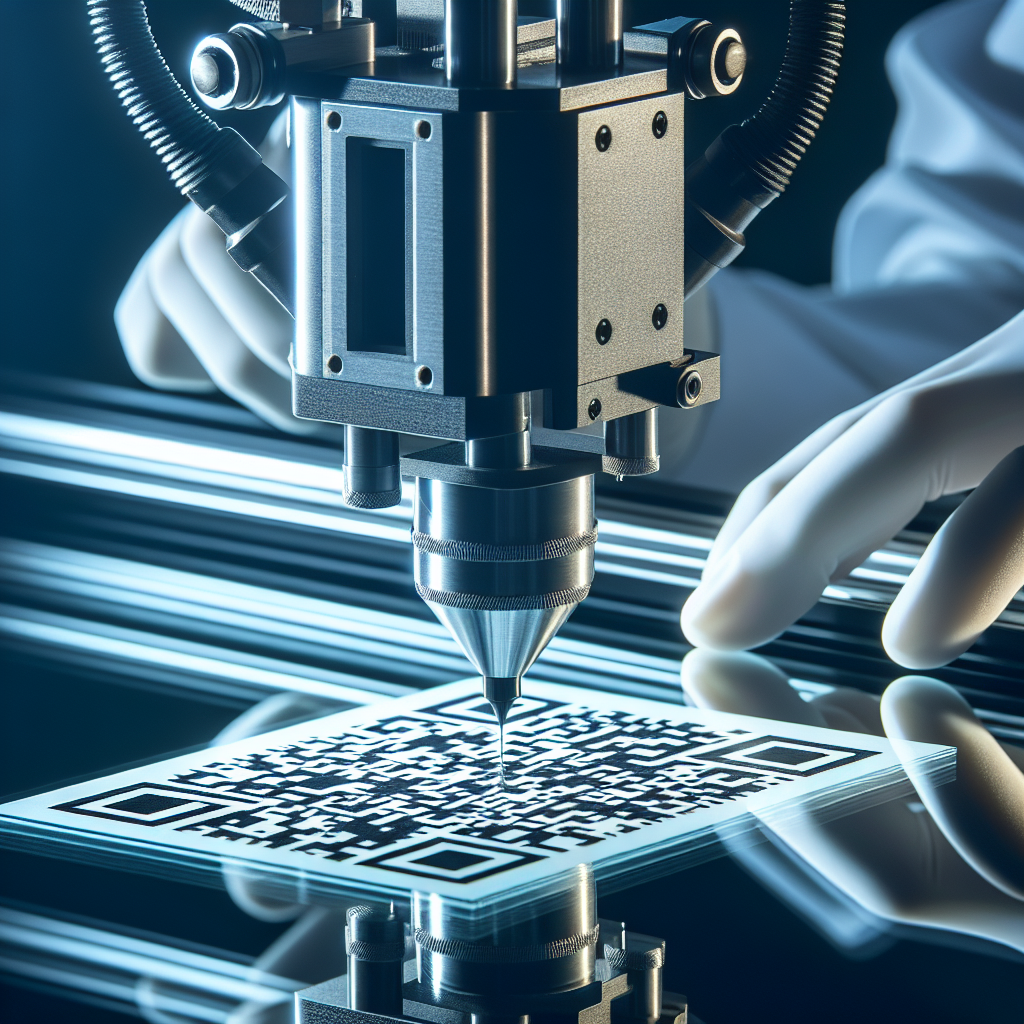

A laser wood cutter is a machine that uses high-powered laser beams to cut and engrave materials, primarily wood. The laser produces intense heat that vaporizes or burns away material, creating precise cuts or engravings. Unlike traditional cutting tools, a laser wood cutter offers unmatched accuracy and speed, making it ideal for both small-scale projects and large-scale production.

The machine typically consists of a laser source, optics to focus the beam, and a CNC (Computer Numerical Control) system that guides the laser according to pre-programmed designs. This setup allows for intricate detailing and complex patterns that would be difficult or time-consuming to achieve manually. The laser wood cutter is not just a cutting tool; it’s a creative powerhouse that can transform raw materials into stunning finished products.

Benefits of Using a Laser Wood Cutter

There are numerous advantages to using a laser wood cutter, especially for those looking to enhance their craftsmanship or streamline production. Here are some key benefits:

- Precision and Accuracy: The laser beam is incredibly precise, allowing for intricate details and clean cuts that are difficult to achieve with traditional tools.

- Speed and Efficiency: Once programmed, a laser wood cutter can rapidly produce large quantities of items, saving time and increasing productivity.

- Versatility: While primarily used for wood, these machines can also cut or engrave other materials like leather, plastic, fabric, and even metal, making them a versatile addition to any workshop.

- Reduced Waste: The precision of the laser minimizes material waste, which is both cost-effective and environmentally friendly.

- Ease of Use: Modern laser wood cutters come with user-friendly interfaces and software, making them accessible even to those without extensive technical knowledge.

Applications of a Laser Wood Cutter

The applications of a laser wood cutter are vast and varied. Here are some common uses:

- Furniture Making: Create custom designs, intricate joinery, and decorative elements for furniture.

- Crafts and Art: Produce one-of-a-kind art pieces, wood engravings, and decorative items like signs, ornaments, and wall art.

- Signage: Engrave or cut detailed signage, including business names, logos, and directional markers.

- Jewelry Making: Cut and engrave materials for jewelry components, such as pendants, beads, and settings.

- Prototyping: Quickly produce prototypes for product design and testing before moving to mass production.

These machines are also used in industries like architecture, interior design, and advertising, where precision and creativity are essential. Whether you’re working on a small-scale project or running a full-fledged workshop, a laser wood cutter can be a game-changer.

How to Choose the Right Laser Wood Cutter

If you’re considering investing in a laser wood cutter, it’s important to choose one that meets your specific needs. Here are some factors to consider:

- Laser Power: The power of the laser determines its cutting capacity and speed. Higher power lasers can cut thicker materials faster, but they may also be more expensive.

- Bed Size: The size of the work area (bed) should accommodate the materials you plan to work with. Measure your typical projects to ensure the bed size is sufficient.

- Software Compatibility: Ensure the machine comes with user-friendly software or supports popular design programs like Adobe Illustrator or CorelDRAW.

- Budget: Determine how much you’re willing to spend. While higher-end models offer more features, there are affordable options that still provide excellent performance for small-scale projects.

For example, the is a popular choice among hobbyists and professionals alike due to its balance of power, precision, and affordability. It’s important to read reviews and compare features before making your final decision.

Maintenance and Safety Tips

Like any powerful tool, a laser wood cutter requires proper maintenance and handling to ensure optimal performance and safety. Here are some tips:

- Regular Cleaning: Keep the machine clean to prevent dust and debris from interfering with its operation. Regularly check and clean the optics to maintain laser focus.

- Laser Safety: Always wear appropriate protective eyewear when operating the machine, as direct exposure to the laser beam can cause serious eye damage.

- Ventilation: Ensure proper ventilation in your workspace to avoid inhaling harmful fumes produced during cutting and engraving.

- Software Updates:

Keep the machine’s software updated to take advantage of new features and improvements.

Frequently Asked Questions

If you’re new to laser wood cutters, here are some common questions and answers to help you get started:

- Q: Can a laser wood cutter be used for cutting metal?

- A: Yes, but it depends on the laser’s power and wavelength. High-power lasers are capable of cutting certain types of metal, though they may require additional setup or modifications.

- Q: How easy is it to learn how to use a laser wood cutter?

- A: Most machines come with intuitive software and user manuals, making them relatively easy to learn. There are also plenty of tutorials available online for those who want to improve their skills.

- Q: What materials can a laser wood cutter engrave?

- A: In addition to wood, these machines can engrave leather, plastic, fabric, glass, and even some types of stone. The key is selecting the right settings and materials for your project.

Conclusion

A laser wood cutter is a powerful tool that can elevate your woodworking projects to new heights. Its precision, versatility, and efficiency make it an invaluable addition to any workshop or creative space. Whether you’re looking to create custom furniture, intricate art pieces, or functional prototypes, this machine has the potential to transform your ideas into reality.

If you’re ready to take the plunge and invest in a laser wood cutter, consider exploring models like the . With proper maintenance and safety precautions, you’ll be well on your way to creating stunning, laser-cut masterpieces.

About the Author

John Doe is a passionate woodworker and tech enthusiast with over 10 years of experience in craftsmanship. He specializes in using innovative tools like laser wood cutters to create unique and functional designs. John enjoys sharing his knowledge through articles and tutorials to help others enhance their woodworking skills.