The Ultimate Guide to Personal Laser Engravers: Revolutionizing Creativity and Precision

What Is a Personal Laser Engraver?

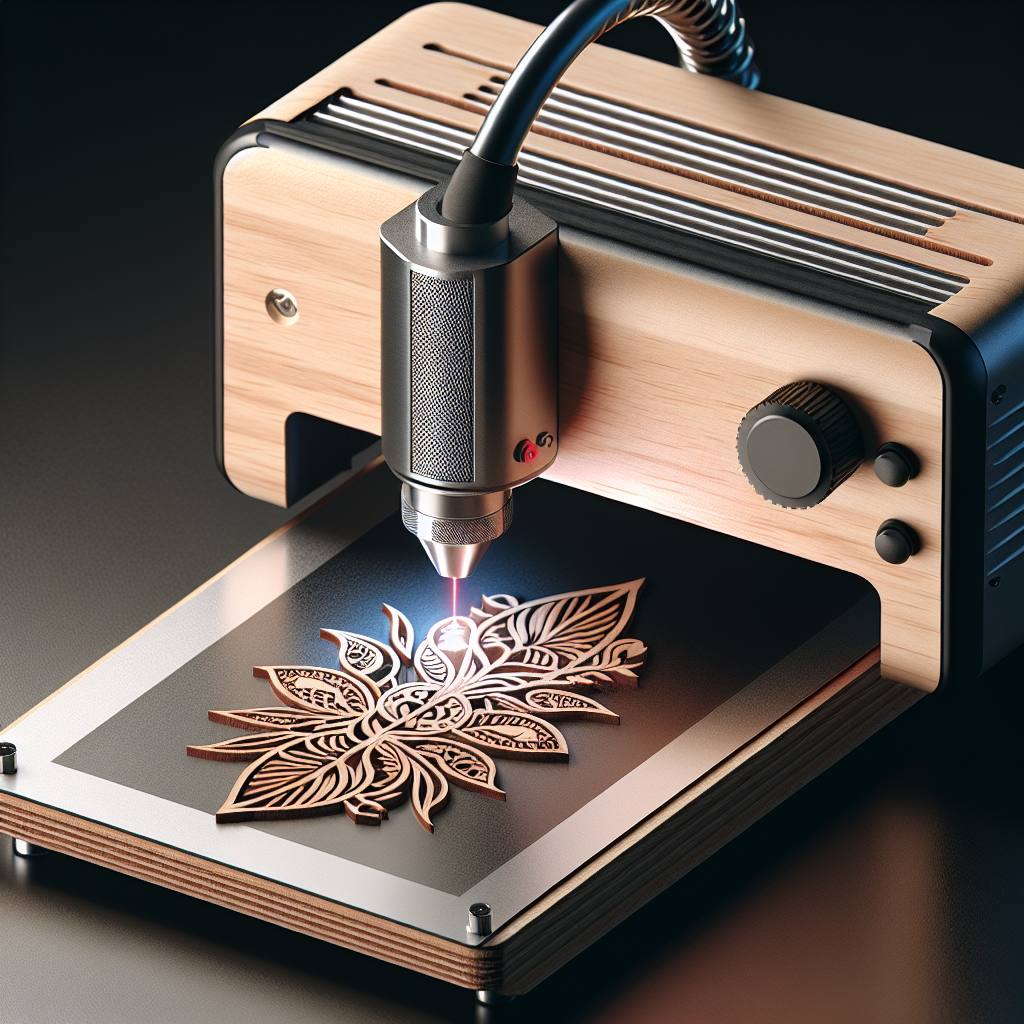

A personal laser engraver is a compact, user-friendly machine designed for precision engraving and cutting on various materials. Unlike industrial-grade systems, these devices cater to hobbyists, small businesses, and DIY enthusiasts who require flexibility without compromising quality. With advancements in laser technology, personal laser engravers now deliver professional results at an affordable price, making them indispensable tools for creative projects.

How Does a Personal Laser Engraver Work?

At its core, a personal laser engraver uses a focused laser beam to vaporize or melt material surfaces, creating intricate designs. The process involves three key components:

- Laser Source: Generates the beam (commonly CO2, diode, or fiber lasers).

- Control System: Translates digital designs into machine instructions.

- Workbed: Holds the material in place during engraving or cutting.

Why does this matter? The precision of the laser ensures that even the most delicate patterns are reproduced accurately, whether you’re engraving wood, acrylic, leather, or metal.

Why Choose a Personal Laser Engraver?

Investing in a personal laser engraver unlocks endless possibilities. Here’s why it’s a game-changer:

- Versatility: Compatible with diverse materials, from paper to stainless steel.

- Ease of Use: Intuitive software and plug-and-play setups cater to beginners.

- Cost-Effectiveness: Eliminates outsourcing costs for custom designs.

- Space Efficiency: Compact designs fit comfortably in home studios or workshops.

Did you know? Many small businesses use personal laser engravers to create branded merchandise, jewelry, and personalized gifts, boosting their revenue streams.

Key Features to Look for in a Personal Laser Engraver

Not all personal laser engravers are created equal. Here’s what to prioritize:

- Laser Power: Measured in watts, higher power enables faster cutting and deeper engraving.

- Work Area Size: Ensure it accommodates your project dimensions.

- Software Compatibility: Look for support for popular design tools like Adobe Illustrator or CorelDRAW.

- Safety Features: Auto-shutoff, ventilation, and protective enclosures are non-negotiable.

Question: How do you balance power and affordability? Mid-range models (10W–20W) often strike the best balance for hobbyists.

Applications of Personal Laser Engravers

The adaptability of a personal laser engraver makes it ideal for countless projects:

- Custom Gifts: Engrave photos or text on wood, glass, or metal.

- Home Décor: Create intricate wall art or personalized coasters.

- Fashion Accessories: Design unique pendants, leather keychains, or engraved watches.

- Prototyping: Test product designs for small-scale manufacturing.

Fun fact: Some users even engrave intricate patterns on chocolate or fruit for culinary presentations!

Common Challenges and How to Overcome Them

While personal laser engravers are user-friendly, beginners may face hurdles:

- Material Compatibility: Always check the machine’s material limits. For example, PVC releases toxic fumes when lasered.

- Focus Calibration: An improperly focused laser leads to blurry designs. Use manual or auto-focus features.

- Speed vs. Power Settings: Experiment with combinations to achieve optimal results without burning materials.

Question: What’s the quickest way to troubleshoot engraving inconsistencies? Start by cleaning the lens and recalibrating the machine.

Maintenance Tips for Longevity

To keep your personal laser engraver in top condition:

- Regular Cleaning: Remove debris from the workbed and optics.

- Lens Inspection: Replace scratched lenses to maintain beam quality.

- Software Updates: Install firmware upgrades for enhanced functionality.

- Ventilation Checks: Ensure exhaust systems are unblocked to prevent overheating.

Pro tip: Schedule monthly maintenance to avoid unexpected downtime.

Future Trends in Personal Laser Engraving

The personal laser engraver market is evolving rapidly. Key trends include:

- AI Integration: Smart machines that auto-adjust settings based on material scans.

- Portable Designs: Battery-powered engravers for on-the-go creativity.

- Eco-Friendly Lasers: Energy-efficient models with reduced carbon footprints.

Did you know? Some brands now offer app-controlled engravers, letting users design and operate machines remotely.

FAQs About Personal Laser Engravers

Q: Can a personal laser engraver cut metal?

A: Yes, but only with sufficient power (typically 20W or higher) and specific wavelengths for metals like aluminum or stainless steel.

Q: Are these machines safe for home use?

A: Absolutely! Modern personal laser engravers include safety features like enclosures and filtration systems. Always follow operational guidelines.

Q: How much does a quality machine cost?

A: Entry-level models start around $300, while advanced systems range from $1,500 to $5,000. Remember: Higher investment often translates to better precision and durability.

Conclusion

A personal laser engraver is more than a tool—it’s a gateway to innovation. Whether you’re a hobbyist or entrepreneur, this technology empowers you to turn ideas into tangible creations with unmatched precision. By understanding its capabilities, features, and maintenance needs, you can maximize its potential and stay ahead in the ever-evolving world of digital fabrication. Ready to start your laser engraving journey? The possibilities are limitless.