The Ultimate Guide to Metal Engraving Laser Machines: Precision and Creativity in One Tool

When it comes to precision and creativity in metalworking, few tools can rival the capabilities of a metal engraving laser machine. These cutting-edge devices have revolutionized industries ranging from jewelry making to industrial manufacturing, offering unparalleled accuracy and versatility. If you’re curious about how these machines work, their benefits, or how they can transform your projects, this article will provide you with all the insights you need. Let’s dive into the world of laser engraving and discover why it has become a cornerstone of modern craftsmanship.

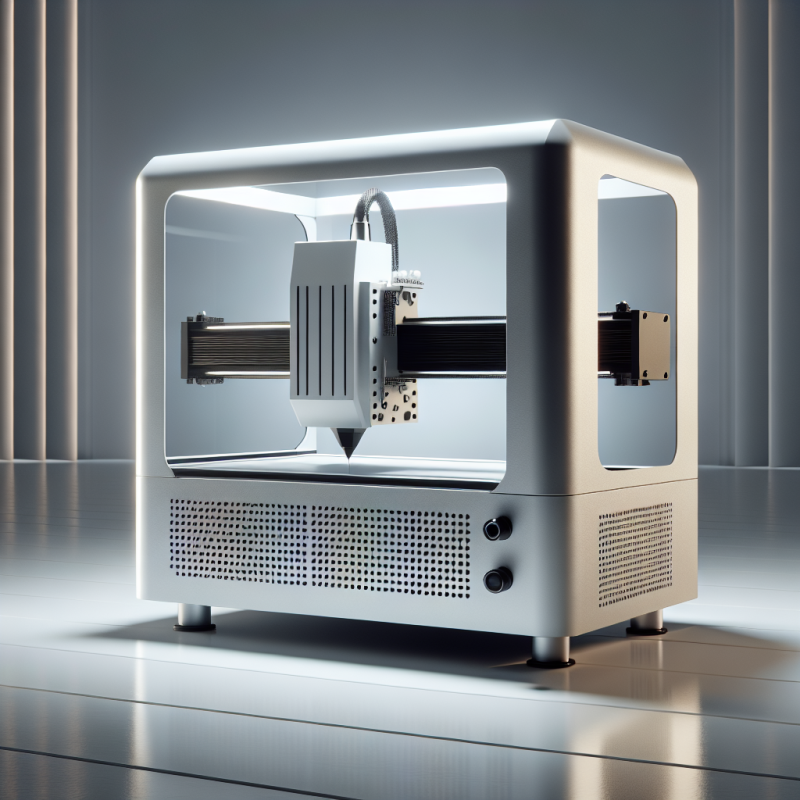

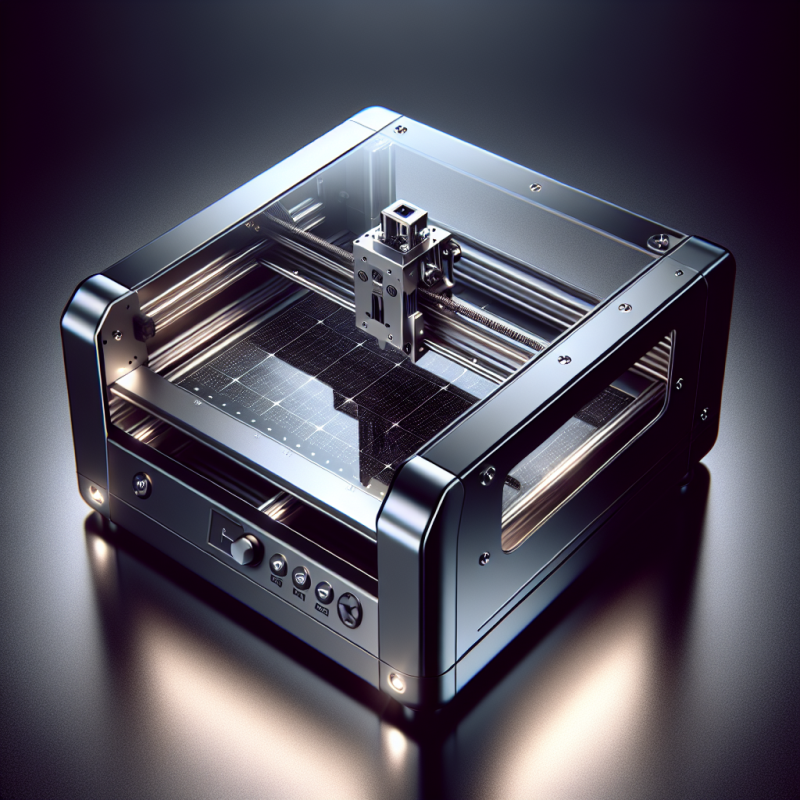

What Is a Metal Engraving Laser Machine?

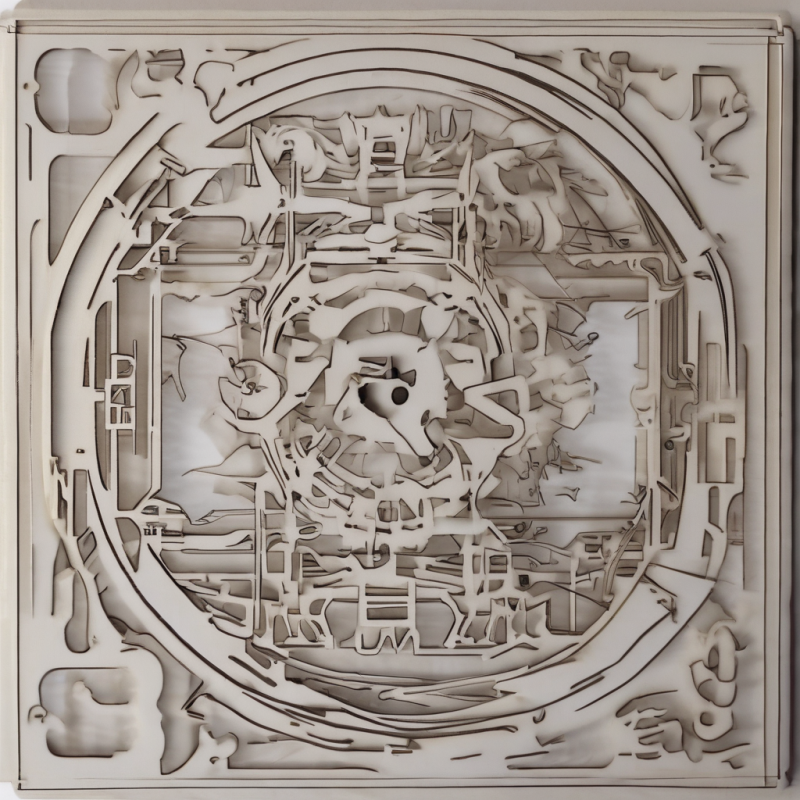

A metal engraving laser machine is a sophisticated tool that uses focused laser beams to etch, cut, or mark metal surfaces with exceptional precision. Unlike traditional engraving methods that rely on mechanical tools, laser engraving machines use light energy to create intricate designs, patterns, and text. This method is not only faster but also produces cleaner, more precise results. The machine operates by directing a high-powered laser at the metal surface, vaporizing or melting the material to create the desired pattern.

One of the key advantages of these machines is their ability to work with various materials, including stainless steel, aluminum, brass, and titanium. Whether you’re creating custom jewelry, decorative signs, or industrial components, a metal engraving laser machine can handle it all with ease. The process is also highly customizable, allowing users to input designs from computer-aided design (CAD) software for precise execution.

How Does a Metal Engraving Laser Machine Work?

To understand the functionality of a metal engraving laser machine, it’s essential to break down its components and process. At its core, the machine consists of a laser source, optics for beam focusing, a motion control system, and software for design input and execution. Here’s a step-by-step overview of how it works:

- Laser Generation: The laser is generated by a source, typically a CO2 or fiber laser, which produces high-energy light beams.

- Beam Focusing: The optics within the machine focus the laser beam to a pinpoint, creating an intense energy concentration capable of melting or vaporizing metal.

- Motion Control: The motion control system directs the laser beam across the surface of the metal, following the design pattern inputted into the software.

- Material Ablation: As the laser hits the metal surface, it removes material layer by layer, creating the desired engraving or cut.

- Cooling and Cleaning: Some machines include cooling systems to prevent overheating and maintain precision. Others may require manual cleaning after use to remove residual debris.

This process is not only efficient but also highly accurate, making it ideal for both small-scale projects and large-scale industrial applications. The ability to control the laser’s intensity and focus allows users to achieve intricate details that would be impossible with traditional engraving tools.

Benefits of Using a Metal Engraving Laser Machine

Investing in a metal engraving laser machine comes with numerous advantages, particularly for businesses and hobbyists looking to enhance their craftsmanship. Here are some of the key benefits:

- High Precision: Laser engraving machines can achieve tolerances as small as 0.1mm, making them ideal for creating intricate designs and detailed patterns.

- Versatility: These machines are compatible with a wide range of metals, allowing users to work with different materials depending on their project requirements.

- Speed: Compared to traditional engraving methods, laser machines significantly reduce production time, especially for complex designs or large batches.

- Customization: The ability to import and manipulate designs from CAD software ensures that each project can be tailored to specific needs and preferences.

- Low Maintenance: Unlike mechanical tools that require frequent replacement of blades or bits, laser machines have fewer moving parts, resulting in lower maintenance costs over time.

These benefits make metal engraving laser machines a valuable asset for businesses looking to improve efficiency, reduce costs, and enhance the quality of their products. Whether you’re producing custom jewelry, industrial components, or decorative items, these machines offer an unmatched level of precision and versatility.

Applications of Metal Engraving Laser Machines

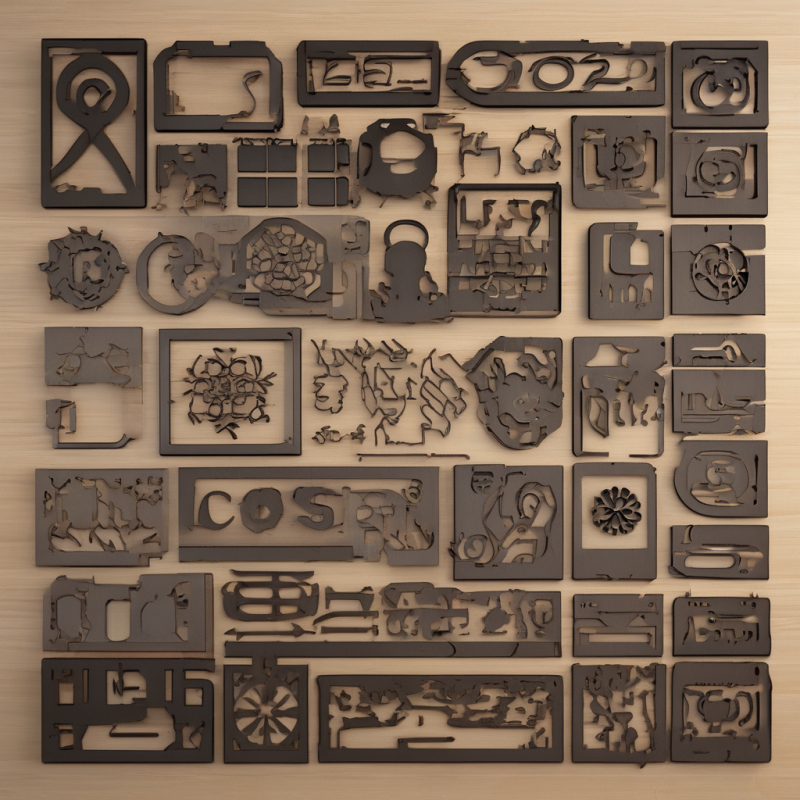

The applications of metal engraving laser machines are vast and varied, spanning multiple industries. Here are some of the most common uses:

- Jewelry Making: From intricate designs on wedding rings to personalized engravings on pendants, laser machines allow for exceptional detail and precision in jewelry production.

- Signage Production: Custom signs, plaques, and nameplates can be created with sharp, lasting text and graphics using laser engraving technology.

- Industrial Manufacturing: The aerospace, automotive, and electronics industries rely on laser machines for creating precise components, markings, and engravings that meet stringent quality standards.

- Customization Services: Businesses offering personalized products, such as engraved firearms or decorative kitchenware, benefit from the speed and accuracy of these machines.

The versatility of laser engraving ensures that it remains a popular choice across industries, providing solutions for both small-scale projects and large-scale production needs.

Choosing the Right Metal Engraving Laser Machine

With so many options available in the market, selecting the right metal engraving laser machine can be a daunting task. Here are some factors to consider when making your choice:

- Laser Type: Decide between CO2 and fiber lasers based on your material requirements. CO2 lasers are better suited for non-metallic materials, while fiber lasers excel at engraving metals with high precision.

- Power Output: Higher power output allows for faster processing of thicker or harder metals but may not be necessary for smaller projects. Choose a machine with the appropriate power level for your needs.

- Software Compatibility: Ensure that the machine supports popular CAD and CAM software to facilitate seamless design integration and customization.

- Build Quality: Invest in machines from reputable manufacturers to guarantee durability, reliability, and customer support. Look for features like sturdy construction, high-quality optics, and advanced cooling systems.

By evaluating these factors, you can select a machine that aligns with your project requirements, budget, and long-term goals.

Frequently Asked Questions About Metal Engraving Laser Machines

If you’re still unsure about whether a metal engraving laser machine is the right choice for your needs, here are answers to some common questions:

- Is laser engraving safe? Yes, when used with proper safety precautions, such as wearing protective eyewear and operating in a well-ventilated area, laser engraving is a safe process.

- Can I use it for both small and large projects? Absolutely! Many laser machines are designed to handle a wide range of project sizes, from tiny engravings on jewelry to larger signage production.

- How much does it cost? The price varies depending on the machine’s specifications and capabilities. Entry-level models can be purchased for around $1,000, while high-end industrial machines may cost upwards of $50,000.

- Do I need special training to operate one? Basic operation is relatively straightforward, but advanced users may benefit from additional training or tutorials to maximize the machine’s potential.

If you’re ready to take your metalworking projects to the next level, a metal engraving laser machine could be the perfect investment. With its precision, versatility, and efficiency, it offers an unmatched solution for both hobbyists and professionals alike.